Integrated packaging device for surface-mounted diode

A technology for packaging devices and diodes, applied in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as inability to connect to the next process, inability to connect to lead frames, and unsatisfactory methods, so as to achieve rapid action and ensure efficiency , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0047] This example provides a chip diode lead frame delivery device, including: a delivery mechanism, a glue tank, a first stroke mechanism, a jumper carrying mechanism, a first stroke mechanism, and the like.

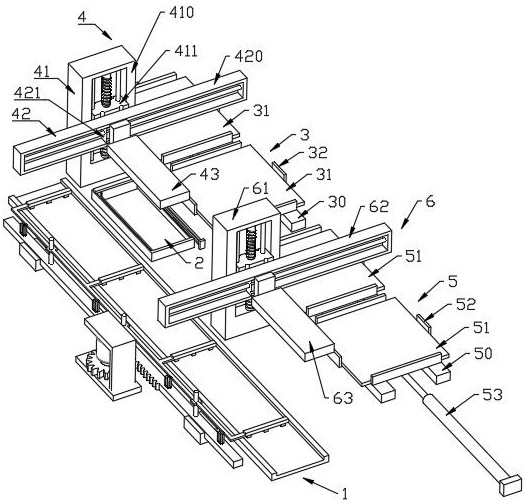

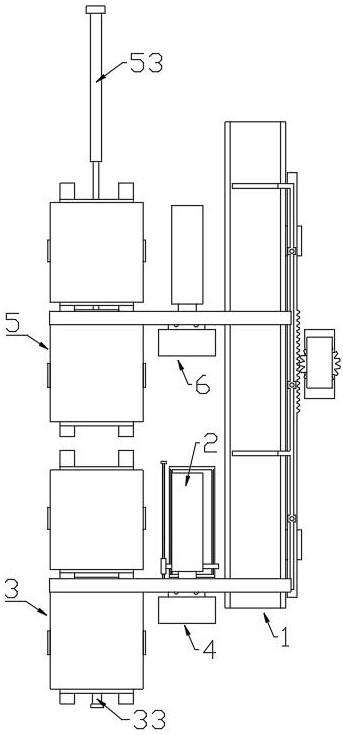

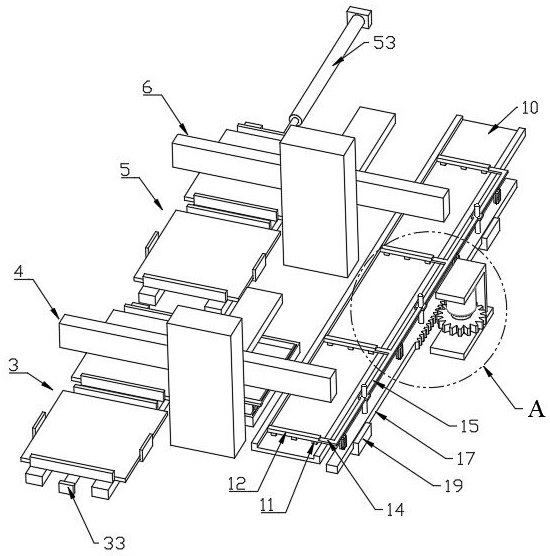

[0048] Specifically, such as Figure 1~3 Shown:

[0049] The conveying mechanism 1 is used for conveying the lead frame; the glue tank 2 is arranged on one side of the conveying mechanism 1 in the length direction to provide glue / colloid. The chip carrying mechanism 3 is located on the outside of the glue tank 2, and includes a first bracket 30, two sets of first four-way limiting plates 32 formed on the first bracket 30, and a A chip template 31, the chip template 31 carries a chip.

[0050]The first stroke mechanism 4 is located at one end of the glue tank 2, and includes a first elevating mechanism 41, a first horizontal linear mechanism 42 disposed on the first elevating mechanism 41, and a sticky core plate 43 disposed on the first horizontal linear mechanism 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com