Three-screw-cap beverage bottle cap screwing machine

A technology of capping machine and beverage bottle, which is applied in the direction of capping containers tightly with caps, sealing machines, threaded bottle caps, etc. It can solve the problems of easy deterioration of beverages, loose caps, deformation and scrapping of bottle caps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

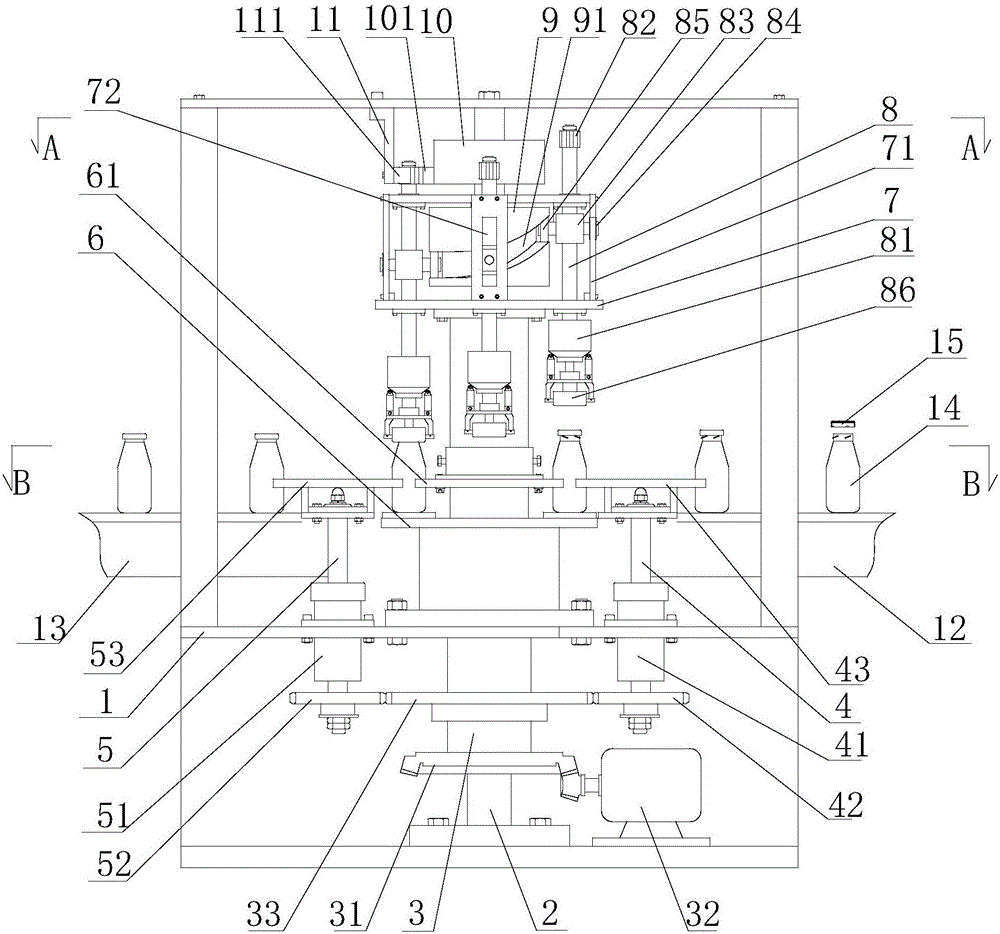

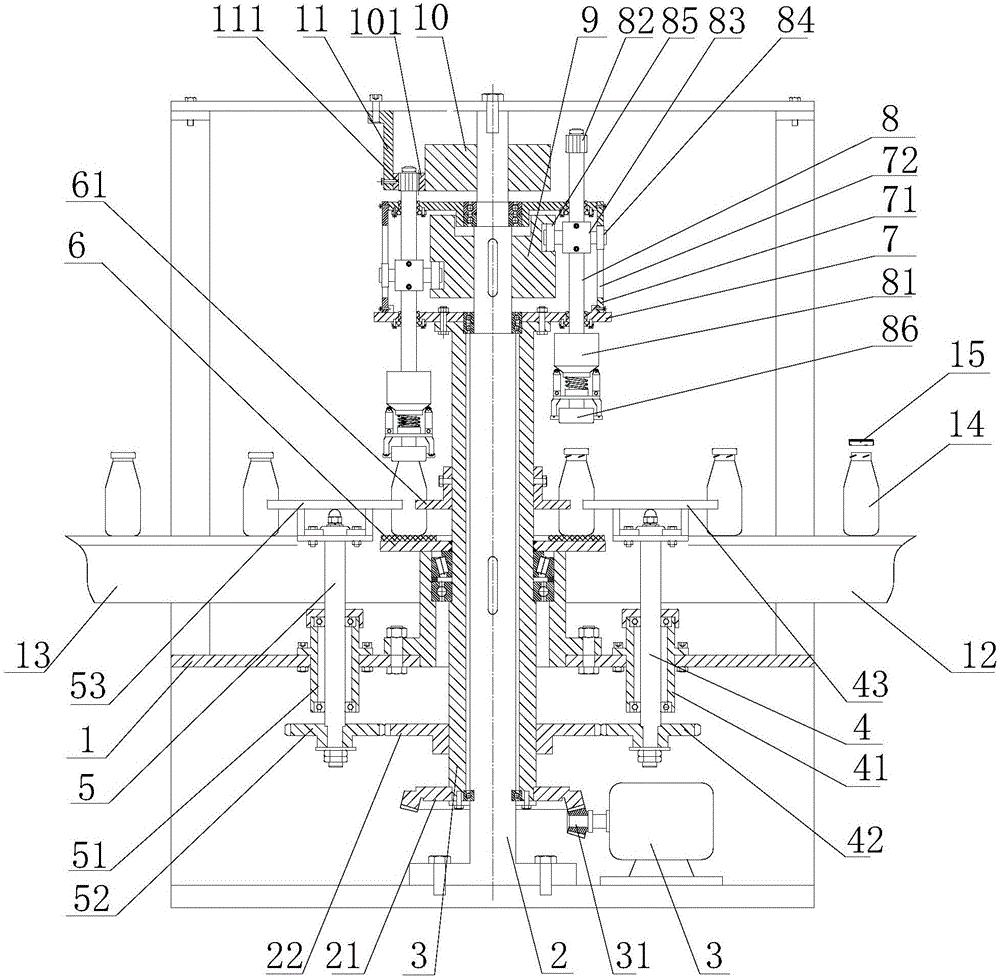

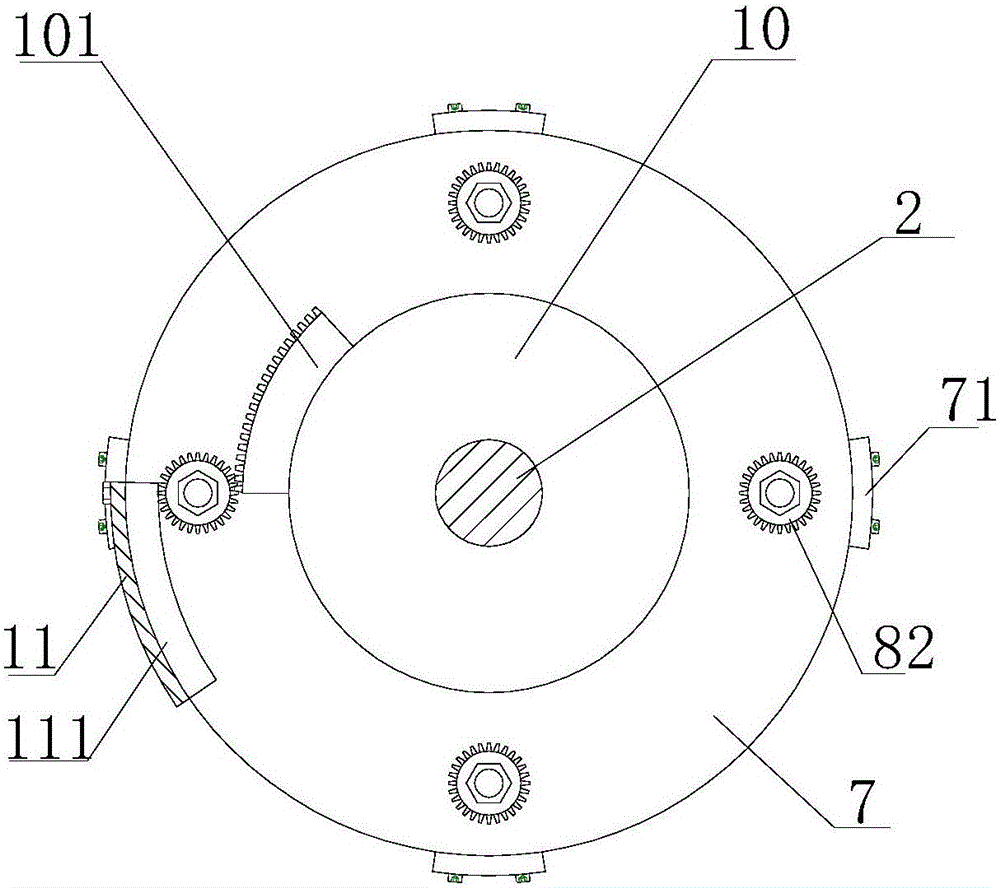

[0016] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 As shown, a three-screwing beverage bottle capping machine includes a frame 1, a bottle-in conveyor mechanism 12, and a bottle-out conveyor mechanism 13. A column 2 is mounted on the frame 1, and a sleeve shaft 3 is mounted on the column 2. , the lower end of the sleeve shaft 3 is equipped with a driving wheel 31, the driving wheel 31 is driven by a motor 32, and a bottle guide mechanism and a capping mechanism are installed on the sleeve shaft 3; Disc 6, capping dial 61, in-out dial drive wheel 33; a bottle-feeding mechanism is installed at the bottle-feeding conveying mechanism 12, and the bottle-feeding mechanism includes a bottle-feeding drive shaft 4, which passes through the bottle-feeding The shaft sleeve 41 is installed on the frame 1, the bottle feeding dial 43 is installed at the upper end of the bottle feeding driving shaft 4, and the bottle feeding driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com