Large-span concrete filled steel pipe tied arch bridge jacking construction method

A large-span, jack-up technology, which is applied to arch bridges, bridges, bridge forms, etc., can solve problems such as short road closure time, tight construction period requirements, and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0190] Such as figure 1 The jacking construction method of a long-span concrete-filled steel pipe tied arch bridge is shown, the bridge to be lifted is a long-span concrete-filled steel pipe tied-arch bridge, and the long-span concrete-filled steel pipe tied-arch bridge includes a main bridge and two connected bridges respectively. The approach bridges on the front and rear sides of the main bridge, the two approach bridges have the same structure;

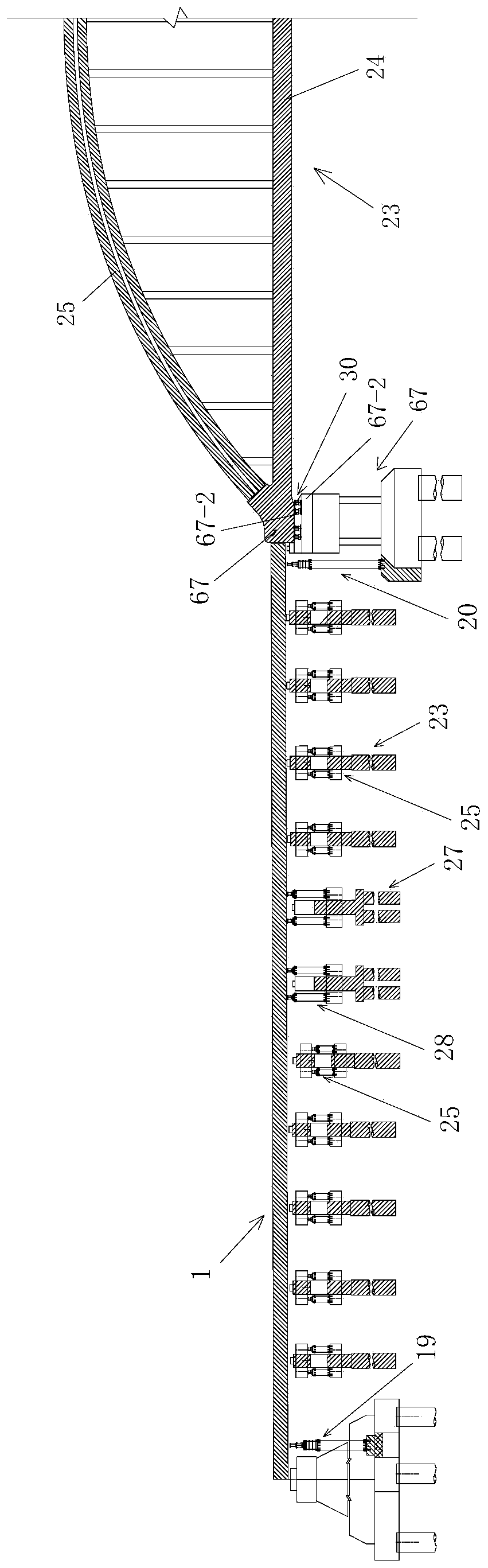

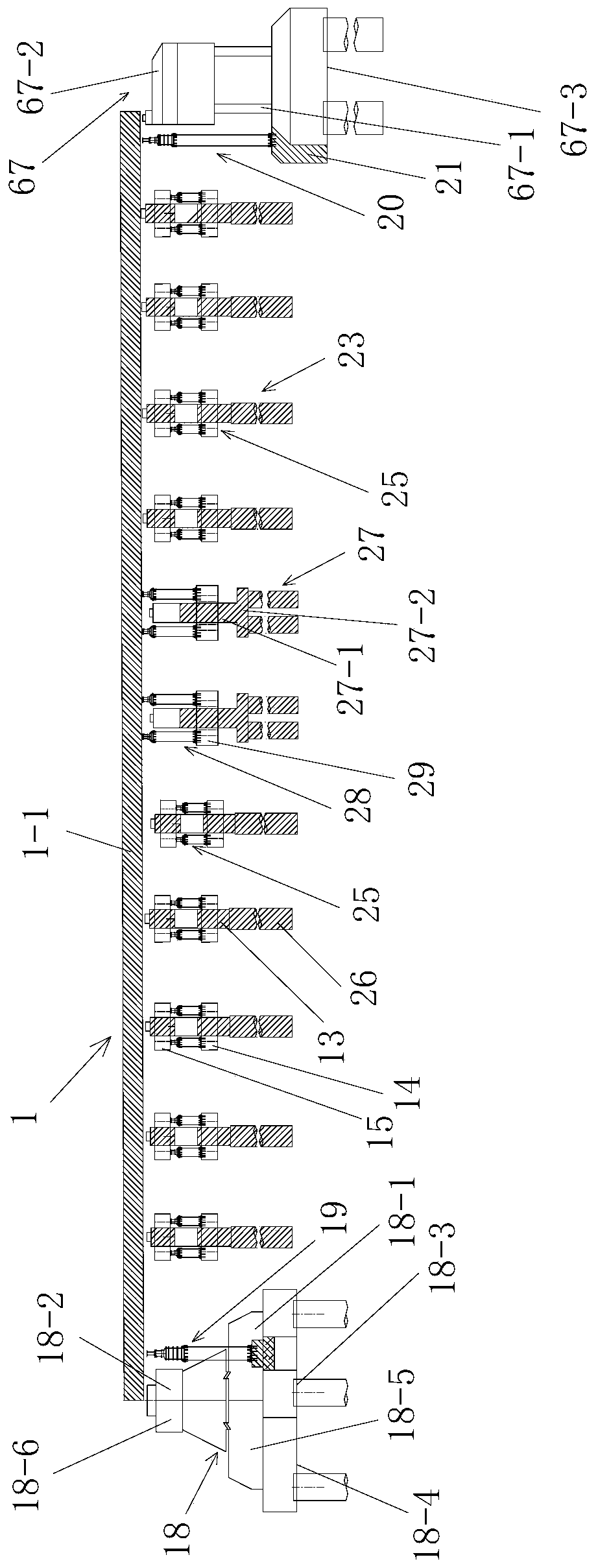

[0191] Such as figure 2 , Figure 22 As shown, the main bridge includes the upper structure of the bridge to be lifted and the lower support structure of the bridge to support the upper structure of the bridge to be lifted; the upper structure of the bridge to be lifted includes two symmetrically arranged arch bridge superstructures 63, and the two Said arch bridge superstructure 63 is all arranged vertically and the two are arranged along the longitudinal bridge direction; Figure 23 Each arch bridge superstructure 63 include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com