Patents

Literature

40results about How to "Avoid construction errors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

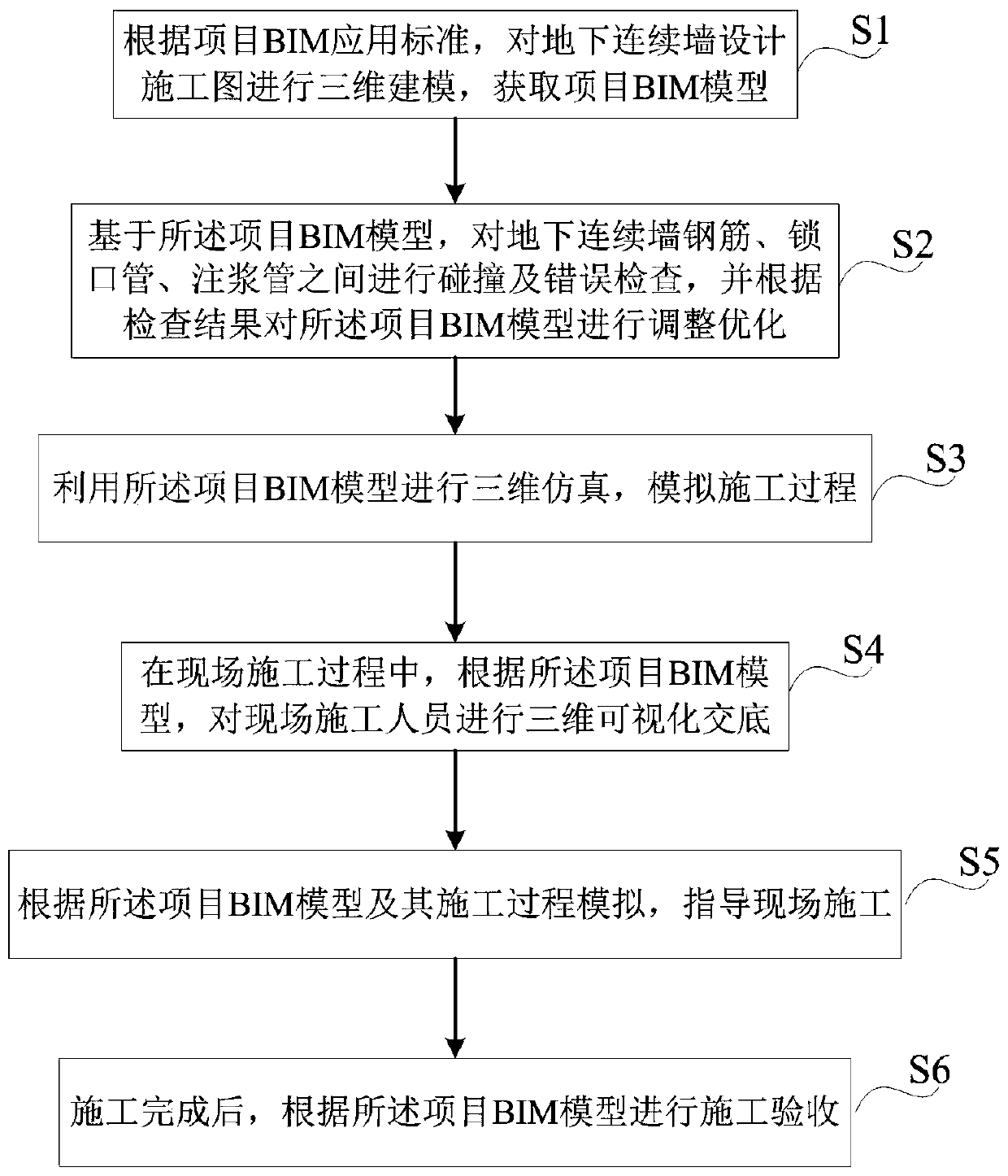

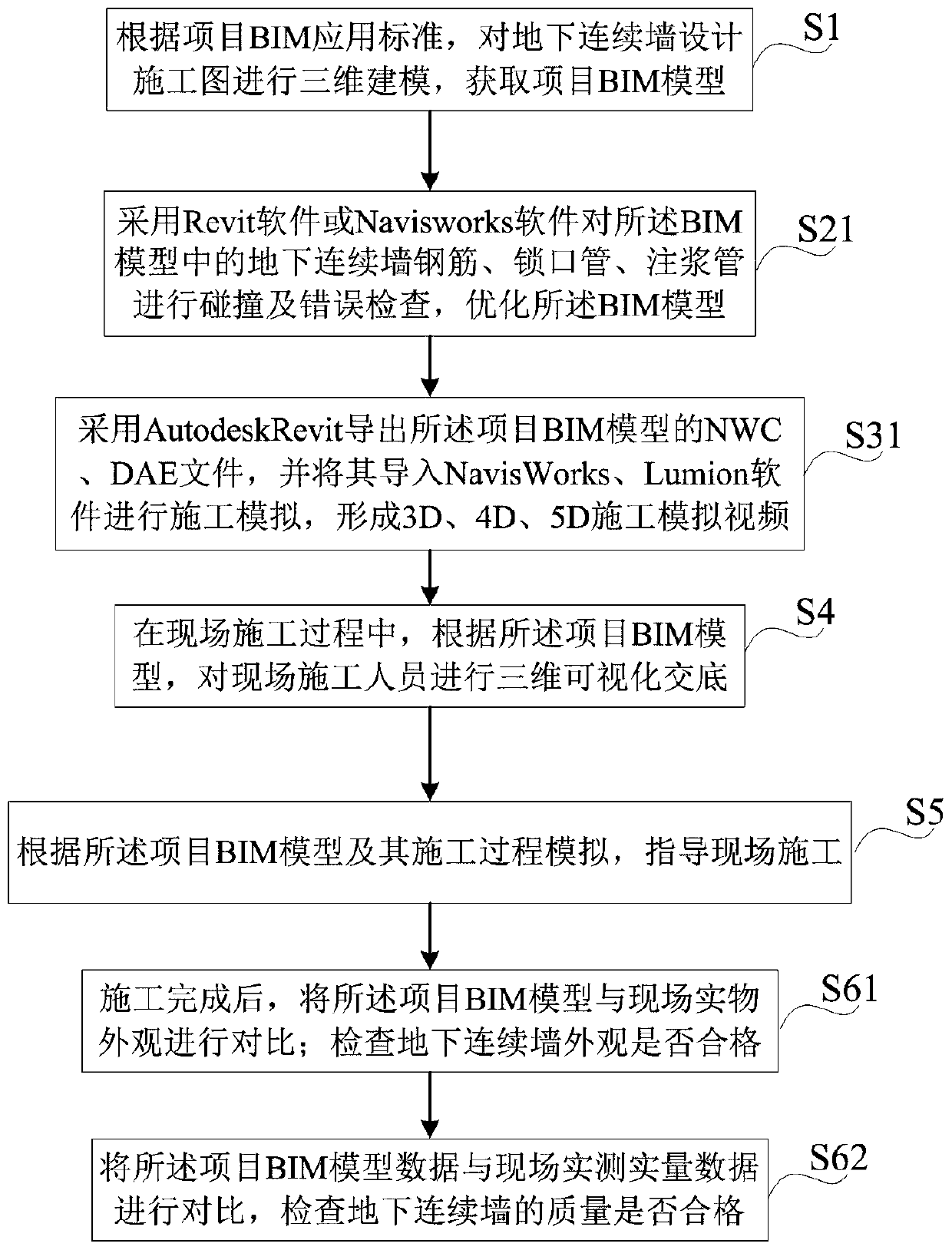

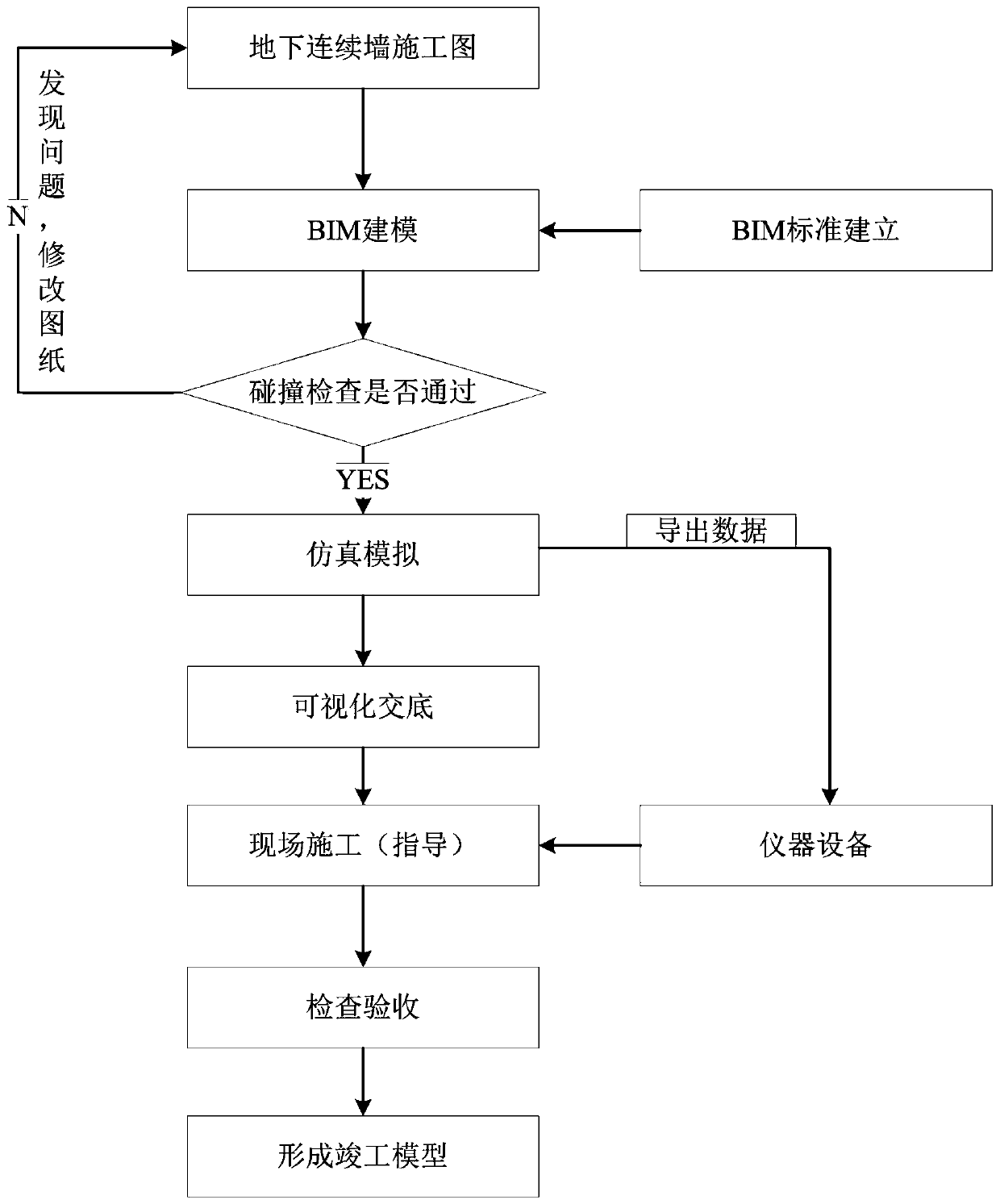

Underground diaphragm wall construction method based on BIM technology

InactiveCN111062081AStrengthen construction managementReduce wasteGeometric CAD3D modellingSlurry wallError check

The invention discloses an underground diaphragm wall construction method based on a BIM technology, and the method comprises the steps: carrying out the three-dimensional modeling of an underground diaphragm wall design and construction drawing according to a project BIM application standard, and obtaining a project BIM model; based on the project BIM model, conducting collision and error inspection on underground diaphragm wall steel bars, fore shaft pipes and grouting pipes, and adjusting and optimizing the project BIM model according to the inspection result; performing three-dimensional simulation by using the project BIM model, and simulating a construction process; in the on-site construction process, conducting three-dimensional visual disclosure on on-site construction personnel according to the project BIM model; guiding field construction according to the project BIM model and the construction process simulation thereof; and after construction is completed, performing construction acceptance according to the project BIM model. By means of the construction method, the construction quality and precision of the underground diaphragm wall are improved, and the construction progress is accelerated.

Owner:SHANGHAI PUDONG ROAD & BRIDGE GRP CO LTD

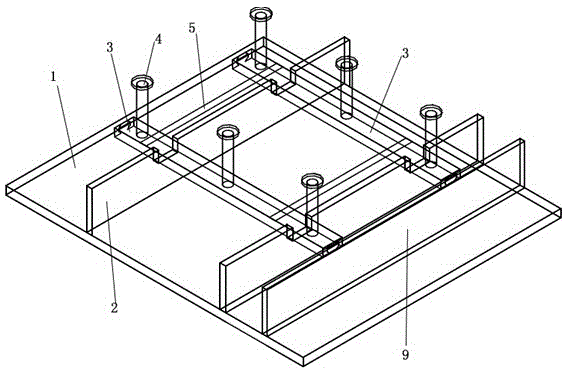

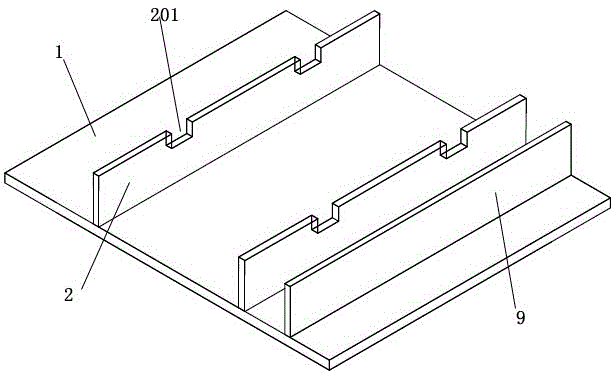

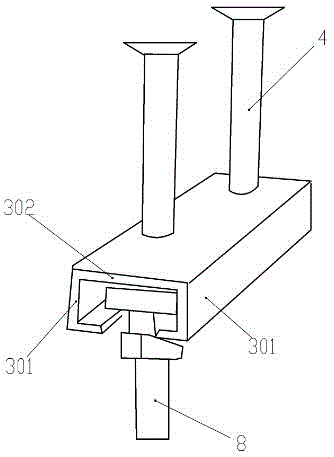

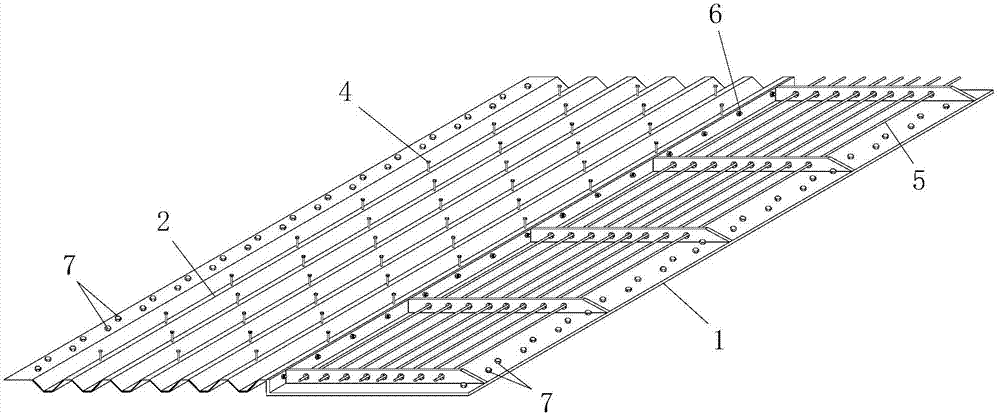

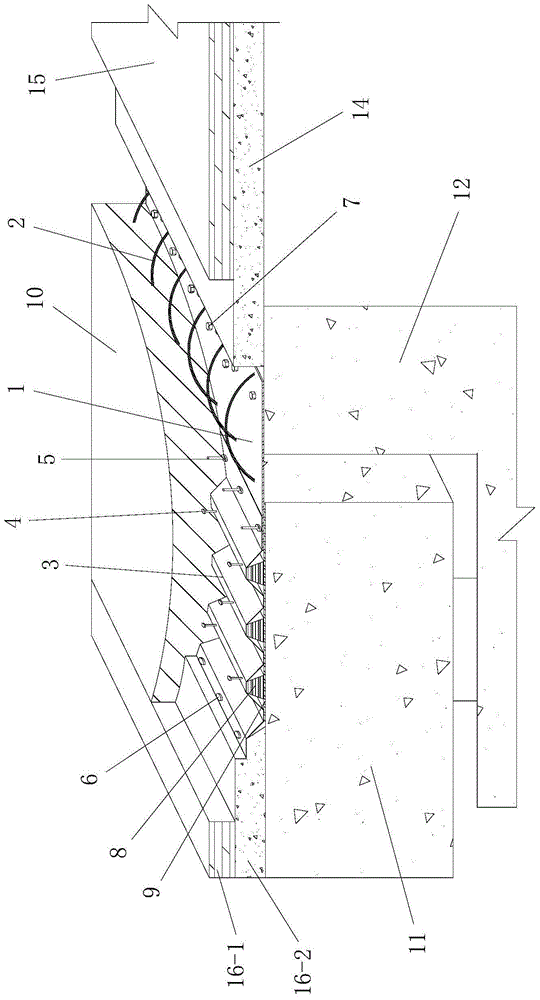

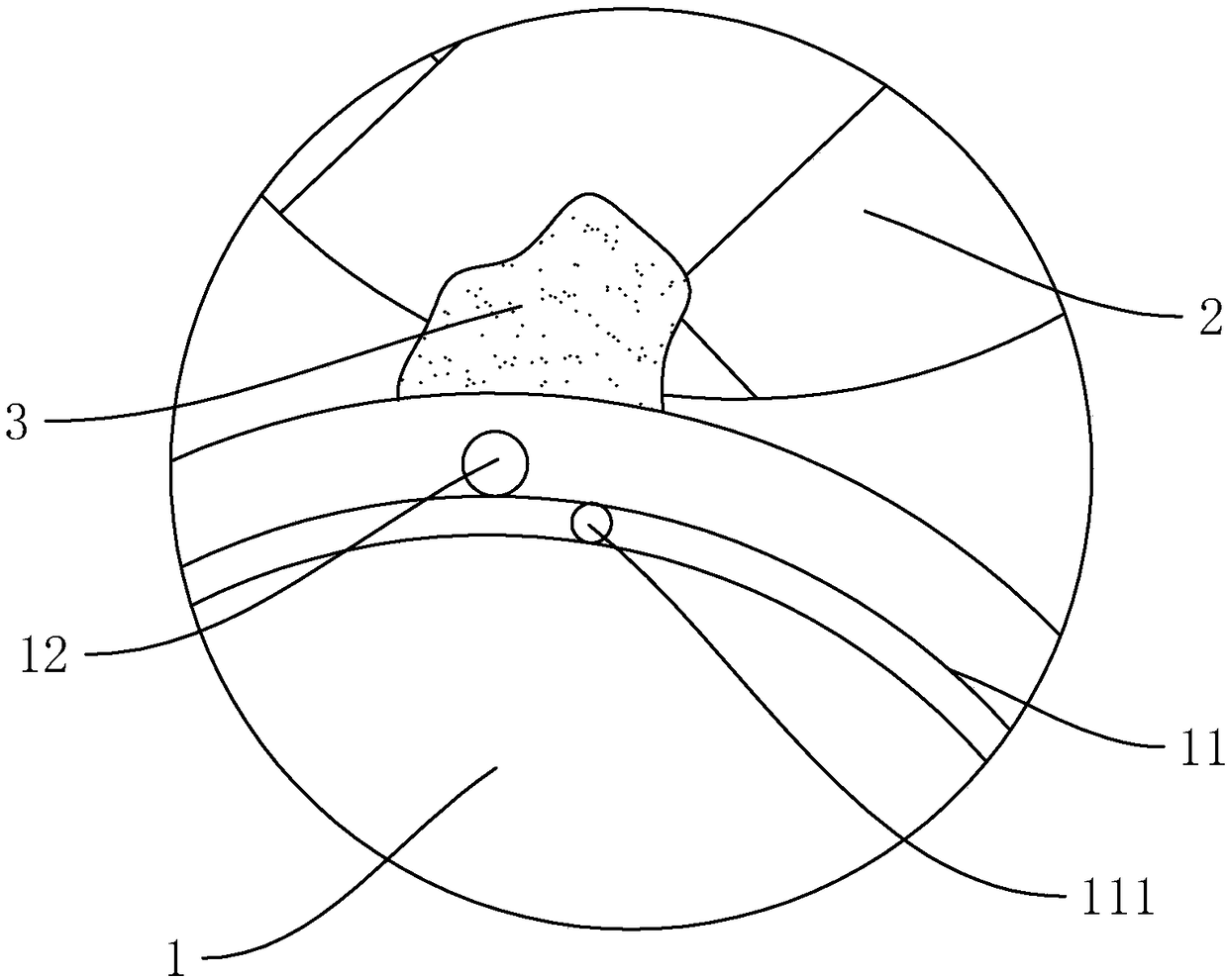

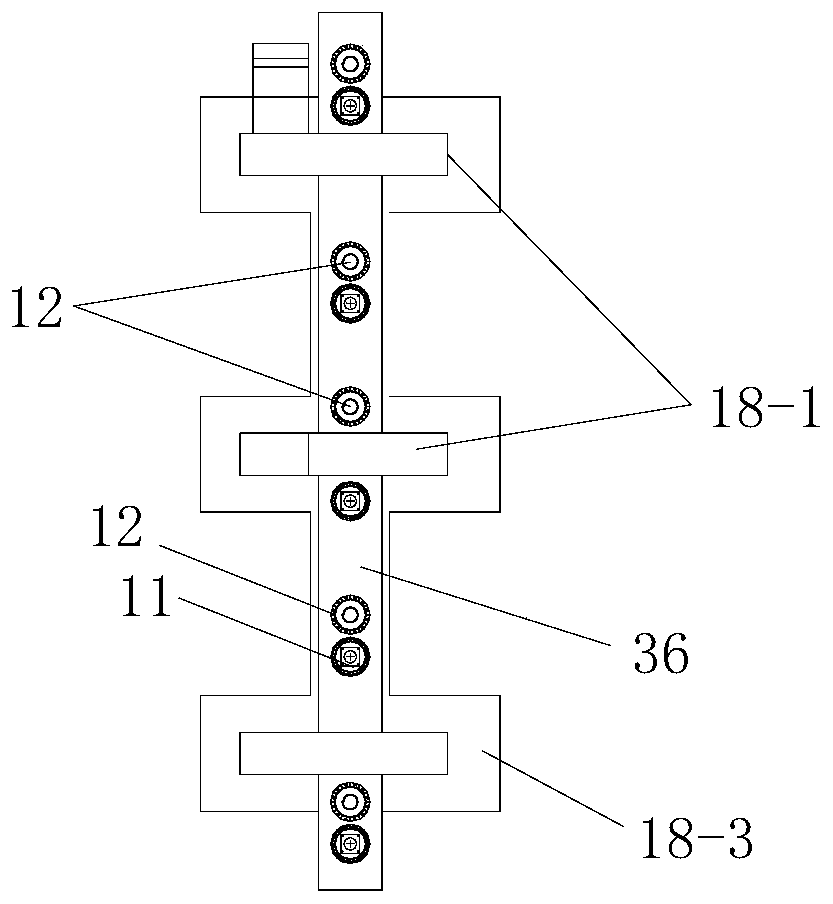

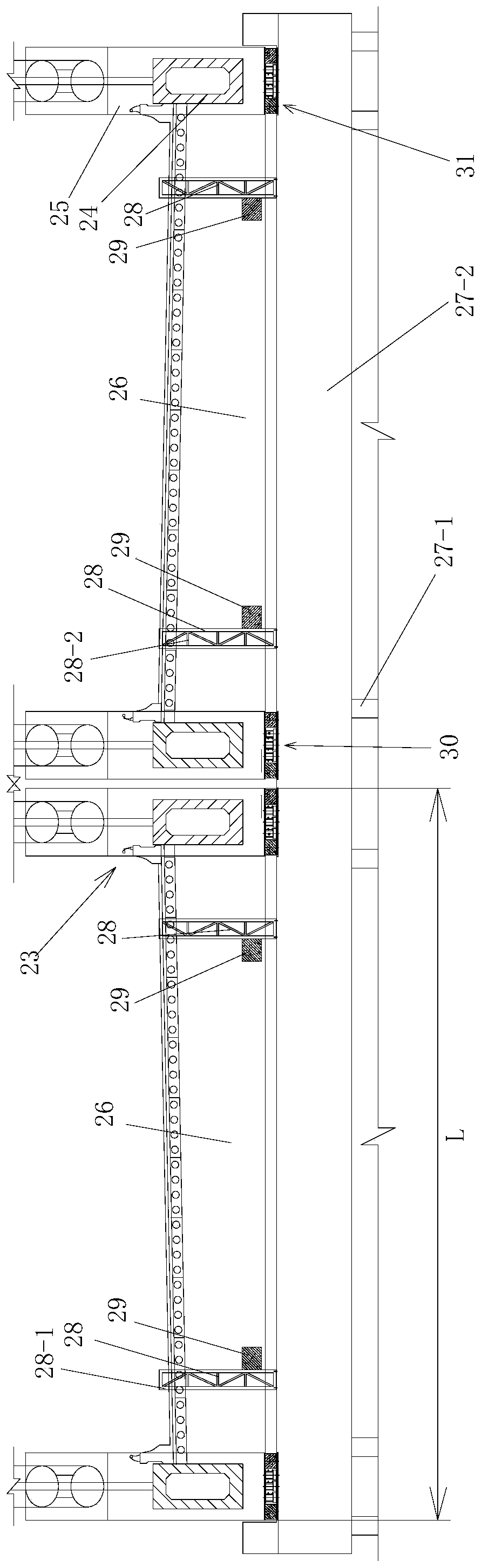

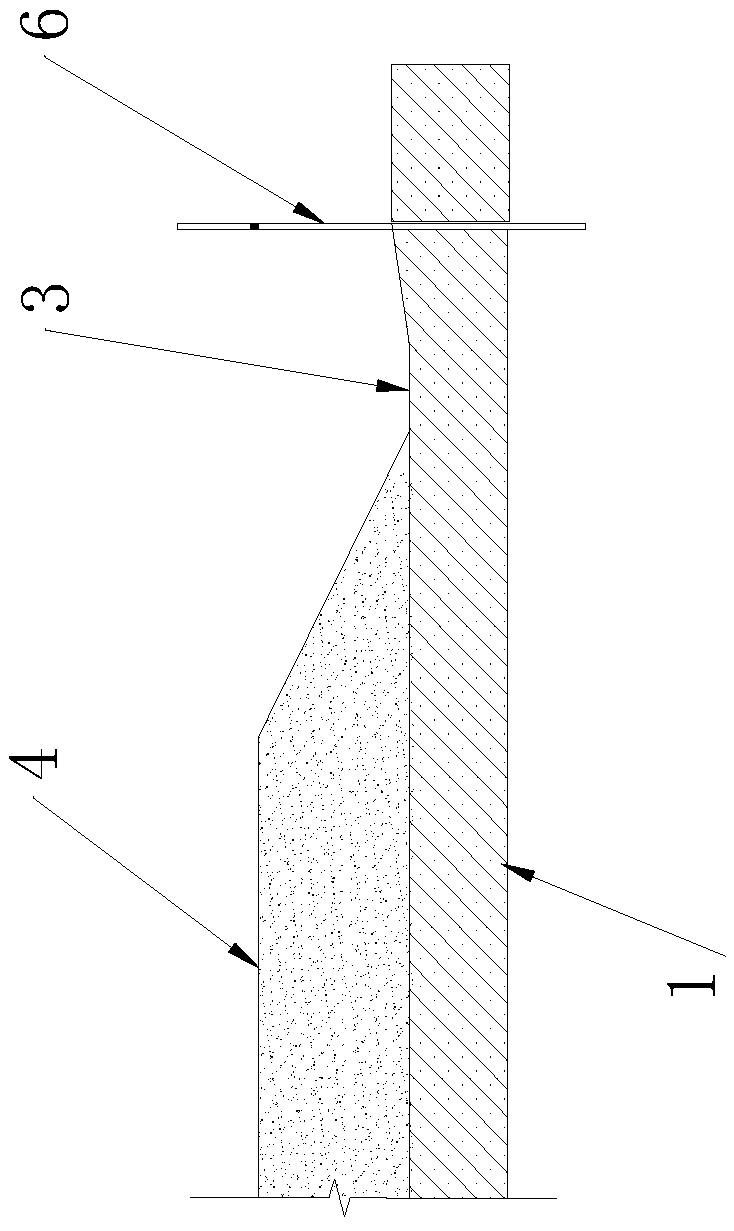

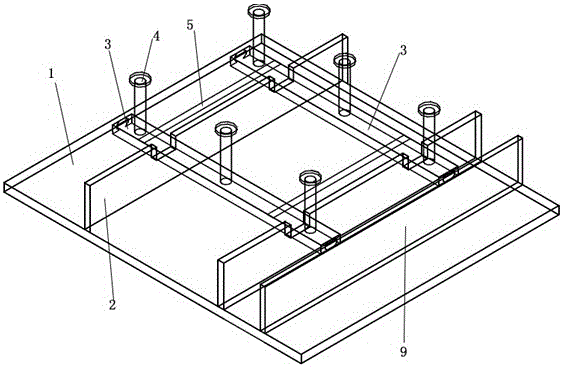

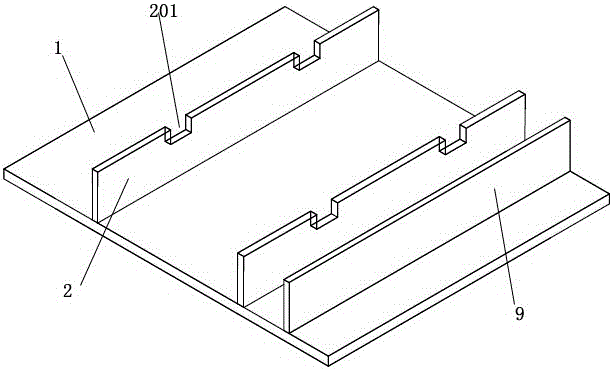

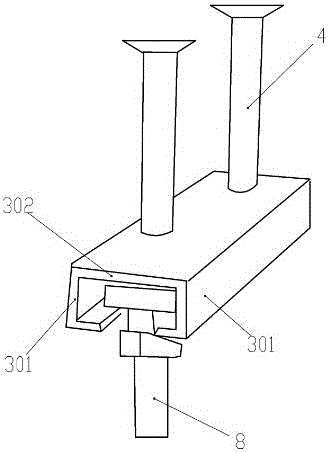

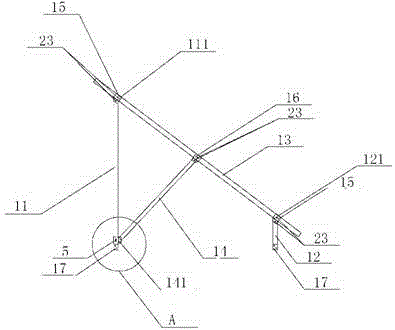

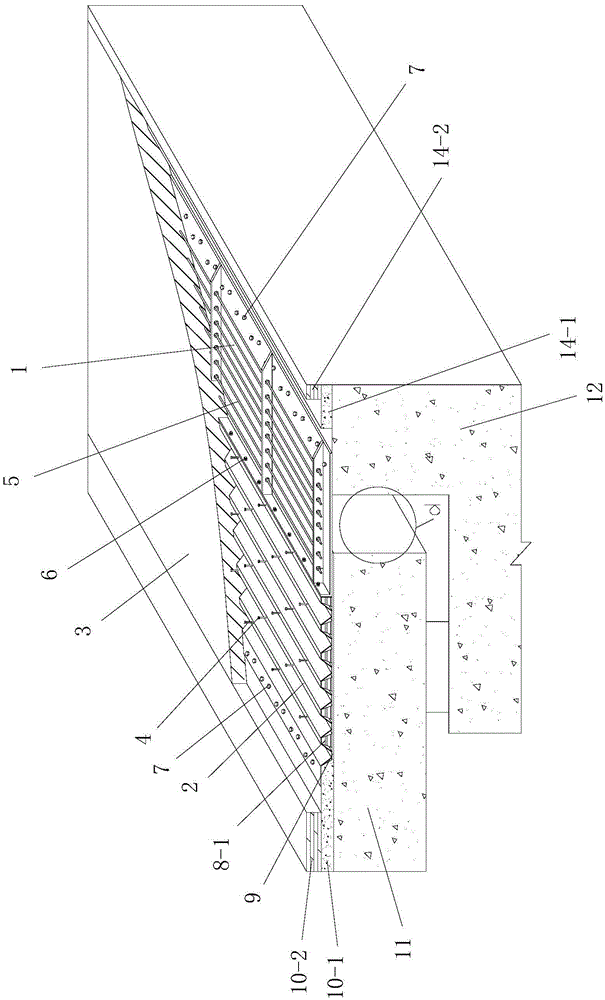

Installation method for conduits of contact rails of magnetism suspension track beams and positioning mold for conduits

ActiveCN105463958AGuaranteed installation accuracyFit tightlyRailway track constructionMagnetic levitationMagnetism

The invention relates to the field of track construction and in particular relates to an installation method for conduits of contact rails of magnetism suspension track beams and a positioning mold for the conduits. The method comprises the following steps: manufacturing the positioning mold for the conduits of the contact rails of the track beams; positioning and perforating side formworks of beam boxes; fixing conduit groups; pouring concrete; and dismantling the formworks. The positioning mold for the conduits of the contact rails of the track beams is used for assembling and grouping to enable the parallel construction error of double conduit groups to meet the design requirement; conduit positioning holes formed in external steel formworks of the track beams can enable the deflection construction error of the conduits to meet the design requirement and can also avoid mortar leakage during concrete pouring; and T-shaped bolts on the conduits are connected with the external steel formworks through the positioning holes, the insides of the T-shaped bolts are connected with the conduits, and nuts are tightened to ensure that indentations are tightly jointed with the conduits, thereby eliminating the embedded construction error of the conduits and the oblique construction error of the double conduit groups, ensuring the construction quality of the conduits and ensuring the installation accuracy of the conduits.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

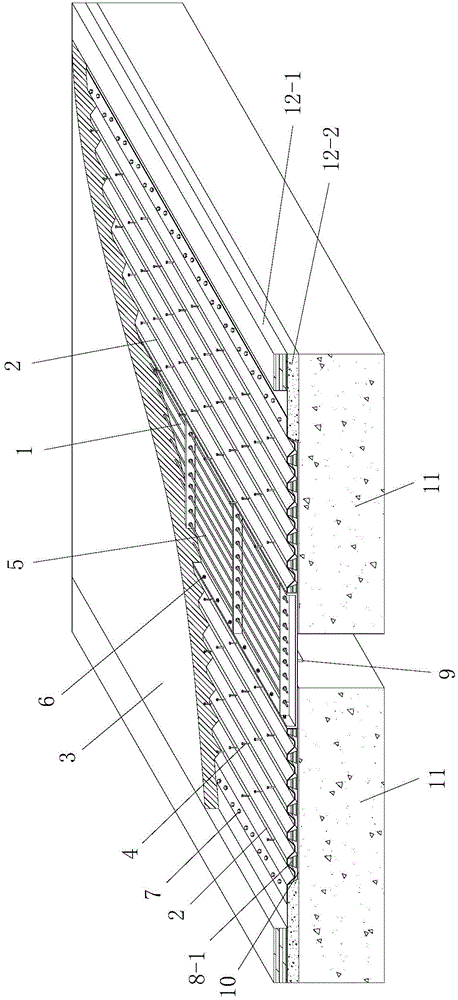

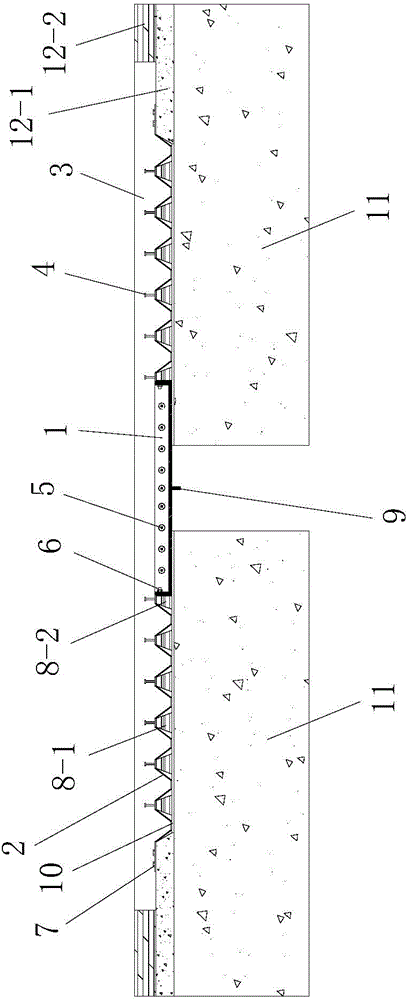

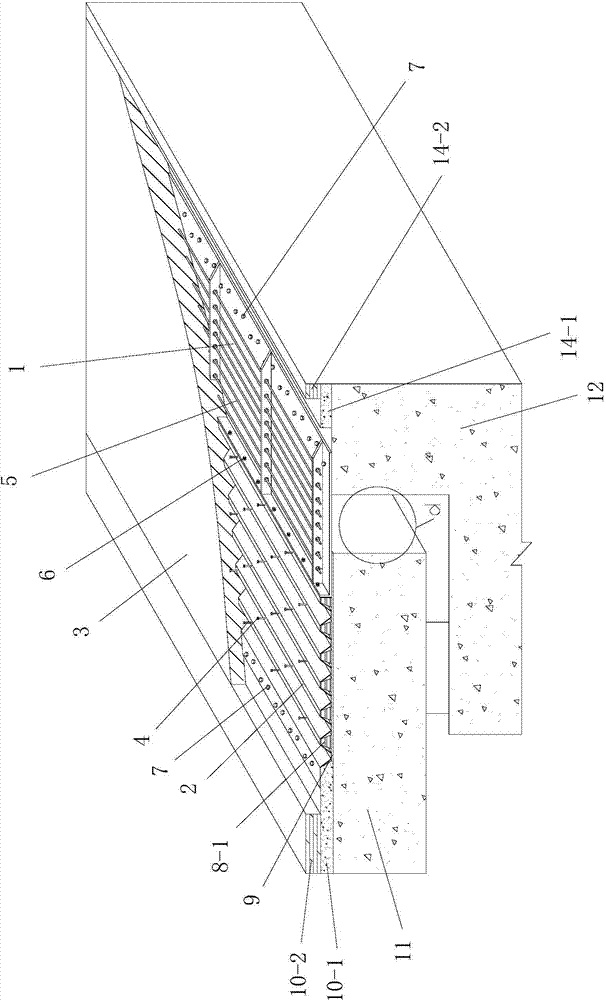

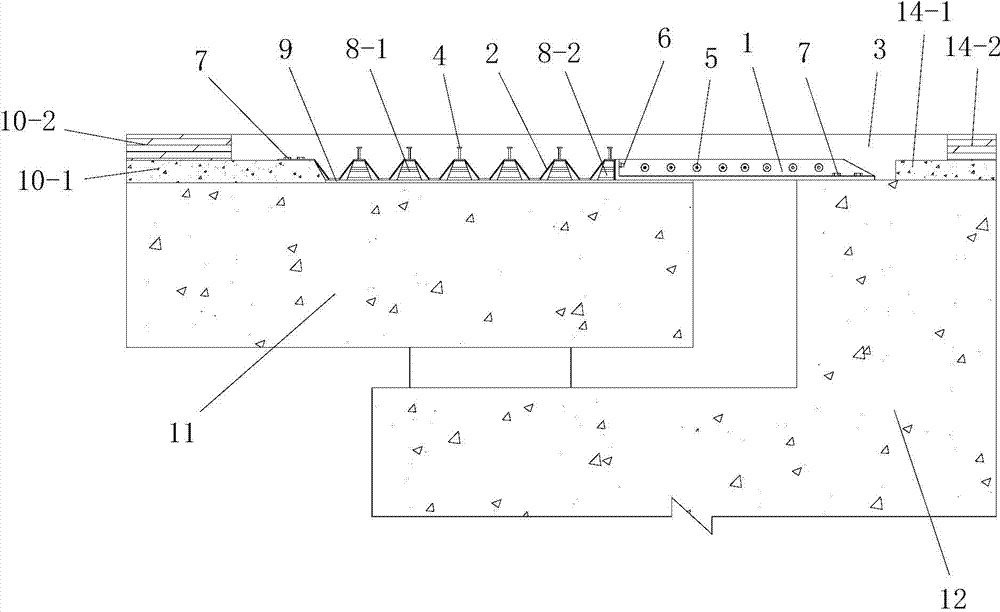

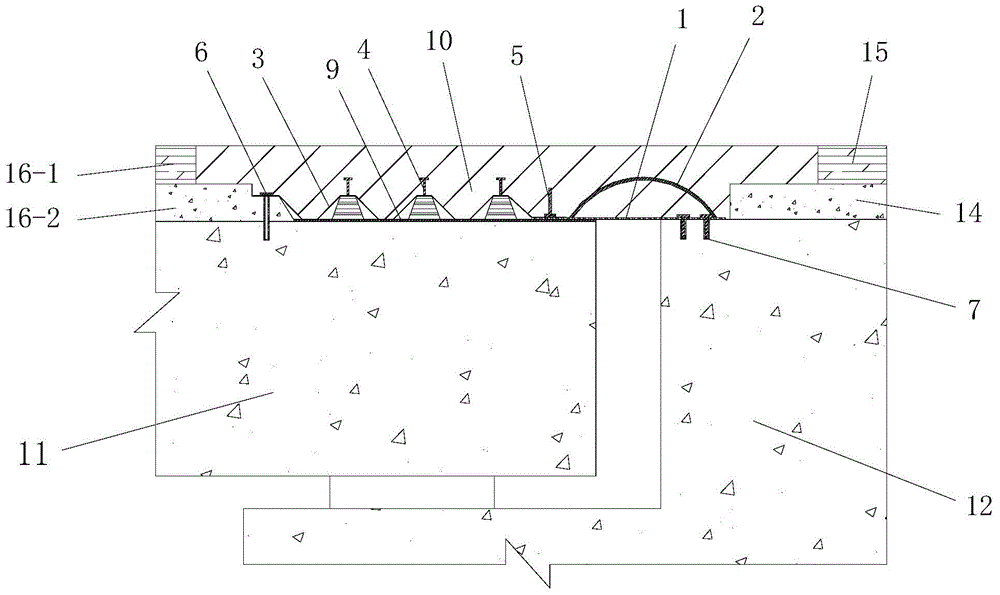

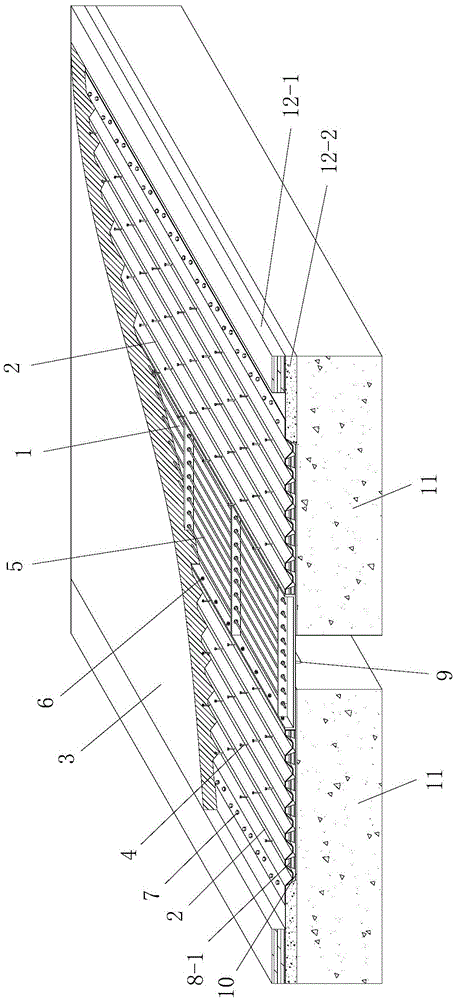

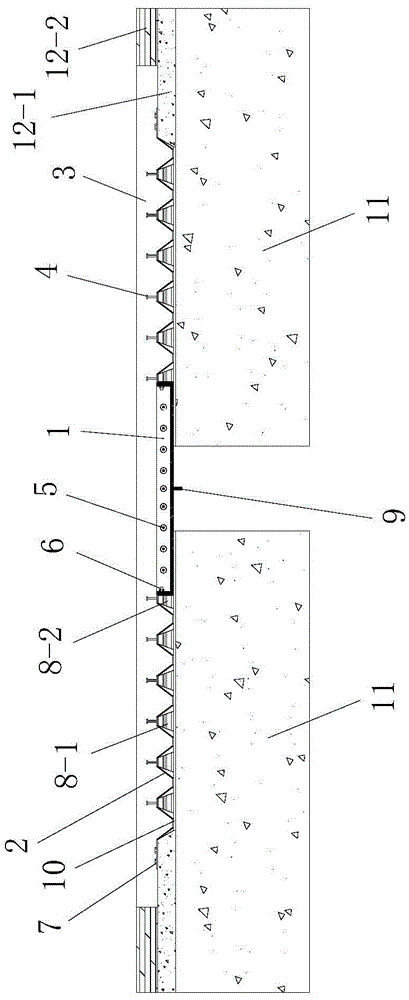

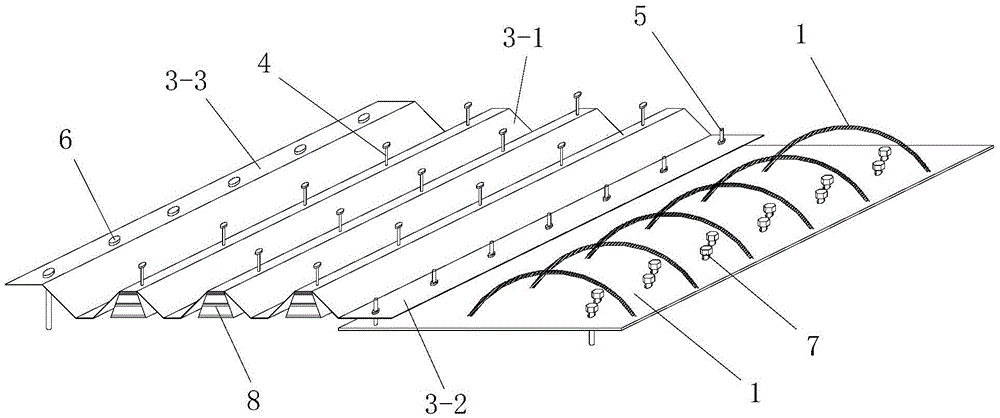

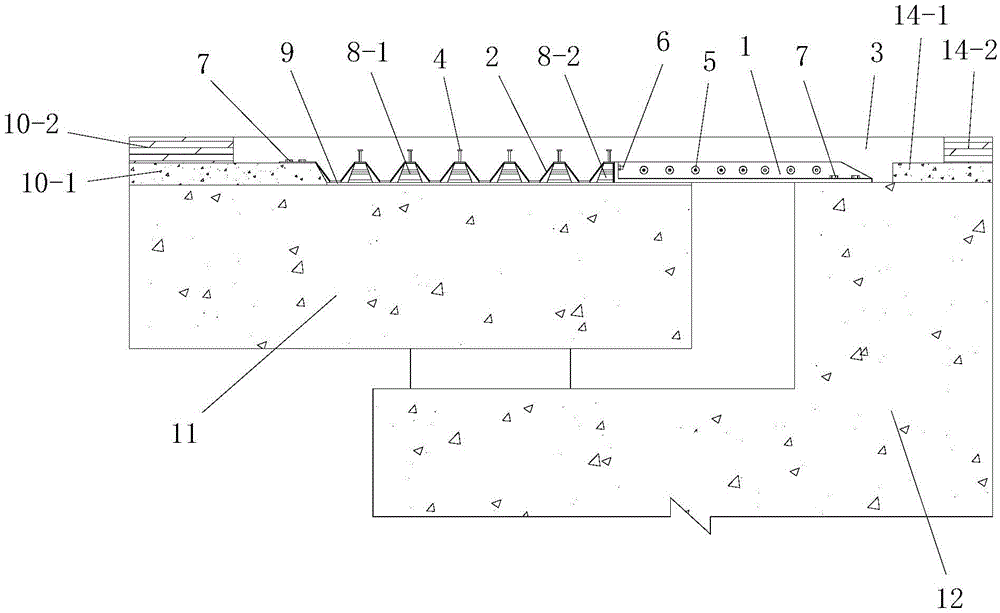

Stiffened joint-crossing plate based bridge deck jointless expansion device and construction method thereof

InactiveCN104674650ASimple structureReasonable designBridge structural detailsBridge erection/assemblyWave shapeExpansion joint

The invention discloses a stiffened joint-crossing plate based bridge deck jointless expansion device and a construction method thereof. The expansion device comprises a prefabricated expansion assembly and an expansion joint filler filled layer filled above the prefabricated expansion assembly, wherein the prefabricated expansion assembly is arranged on an expansion joint reserved between every two adjacent girder segments, and a sliding layer is laid on a girder exposed segment of each girder segment; the prefabricated expansion assembly comprises a stiffened joint-crossing plate and two wave-shaped expansion plates. A construction method for an expansion device to be repaired comprises the steps of cleaning an original bridge expansion device, constructing reserved mounting grooves, constructing the sliding layers, carrying out field assembly and mounting on the prefabricated expansion assembly and constructing the expansion joint filler filled layer. A construction method for an expansion device to be constructed comprises the steps of prefabricating the prefabricated expansion assembly, carrying out field assembly on the prefabricated expansion assembly, constructing the sliding layers, mounting the prefabricated expansion assembly and constructing bridge deck pavement structures and the expansion joint filler filled layer. The stiffened joint-crossing plate based bridge deck jointless expansion device and the construction method thereof have the advantages that the design is reasonable, the construction is convenient, the use effect is good, and multiple problems of the existing expansion devices can be solved.

Owner:XIAN HIGHWAY INST

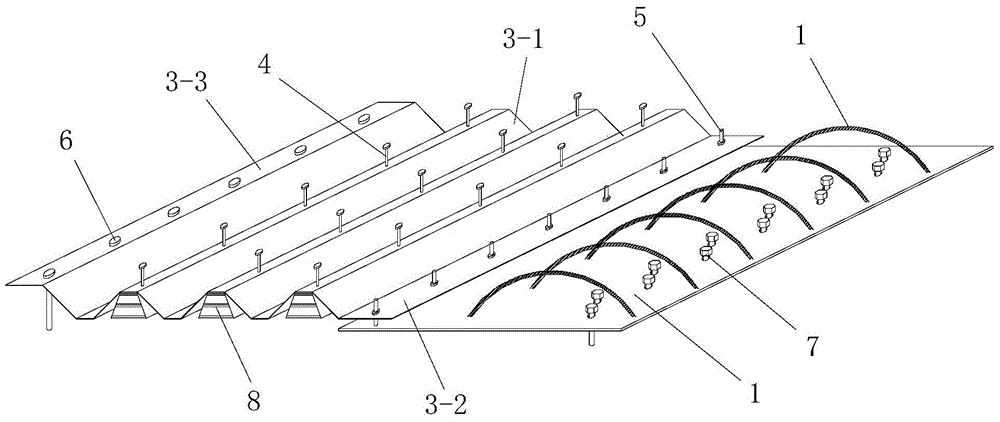

Bridge seamless telescopic device and construction method of device

InactiveCN104594190ASimple structureWell formedBridge structural detailsBridge erection/assemblyWave shapeArchitectural engineering

The invention discloses a bridge seamless telescopic device and a construction method of the device. The bridge seamless telescopic device comprises a main beam span telescopic device and a bridge abutment telescopic device, wherein the main beam span telescopic device comprises a first prefabricated telescopic component and a first telescopic joint filler filling layer; the bridge abutment telescopic device comprises a second prefabricated telescopic component and a second telescopic joint filler filling layer; the first prefabricated telescopic component and the second prefabricated telescopic component are formed by reinforced joint-crossing plates and wave-shaped telescopic plates. A construction method of a telescopic device to be repaired comprises the following steps: cleaning an original bridge telescopic device, constructing a preserved mounting slot, constructing a sliding layer, assembling and mounting prefabricated telescopic components, and constructing telescopic joint filler filling layers. A construction method of a telescopic device to be constructed comprises the following steps: prefabricating and processing prefabricated telescopic components, assembling the prefabricated telescopic components on site, constructing a sliding layer, mounting prefabricated telescopic components, paving a structure and constructing telescopic joint filler filling layers. The bridge seamless telescopic device is reasonable in design, convenient to construct and high in using effect, and can be used for solving various problems of the existing telescopic device.

Owner:XIAN HIGHWAY INST

Abutment hidden expansion device and construction method thereof

InactiveCN104762873AWell formedSimple structureIn situ pavingsBridge structural detailsExpansion jointAbutment

The invention discloses an abutment hidden expansion device and a construction method thereof. The expansion device comprises a prefabricated expansion component arranged on an abutment expansion joint, and an expansion joint filler filling layer filled in the upper side of the prefabricated expansion component, wherein a bridge deck pavement structure is paved on a main beam; a slide layer is paved on an exposed section of the main beam; a road surface pavement layer is arranged at the outer side of the upper part of an abutment; the prefabricated expansion component comprises a reinforced joint plate and a waveform expansion plate; a construction method of an expansion device to be repaired comprises the steps of cleaning of an original bridge expansion device, construction of a reversed mounting groove, construction of the slide layer, field assembly and installation of the prefabricated expansion component and construction of the expansion joint filler filling layer; and a construction method of an expansion device to be constructed comprises the steps of prefabrication of the prefabricated expansion component, field assembly of the prefabricated expansion component, construction of the slide layer, installation of the prefabricated expansion component and construction of the bridge deck pavement structure and the expansion joint filler filling layer. The abutment hidden expansion device and the construction method thereof have the advantages of reasonable design, convenience for construction and good use effect, and can solve multiple problems in traditional expansion devices.

Owner:XIAN HIGHWAY INST

Corrugated steel plate built-in seamless expansion device between girder and bridge abutment and construction method of seamless expansion device

InactiveCN104594191AWell formedSimple structureBridge structural detailsBridge erection/assemblySteel platesSteel bar

The invention discloses a corrugated steel plate built-in seamless expansion device between a girder and a bridge abutment and a construction method of the seamless expansion device. The expansion device comprises prefabricated steel plate elements distributed on a bridge abutment expansion joint and expansion joint filler packing layer filled above the prefabricated steel plate elements; the prefabricated steel plate elements comprise straight steel plates, corrugated steel plates and a plurality of arched reinforcing steel bars; a plurality of shear pins are fixed on the corrugated steel plates; a sliding layer is paved on the girder exposed section; the construction method of the to-be-repaired expansion device comprises the following steps: cleaning the original bridge expansion device, constructing preserved mounting grooves, constructing the girder sliding layer, assembling the prefabricated steel plate elements in the field, and mounting and constructing the expansion joint filler packing layer; the construction method of the to-be-constructed expansion device comprises the following steps: prefabricating and processing the prefabricated steel plate elements, assembling the prefabricated steel plate elements in the field, constructing the girder sliding layer, mounting the prefabricated steel plate elements, and constructing the bridge deck pavement structure and the expansion joint filler packing layer. The corrugated steel plate built-in seamless expansion device disclosed by the invention is reasonable in design, convenient to construct, and good in use effect, and can solve a plurality of problems in the existing expansion device.

Owner:XIAN HIGHWAY INST

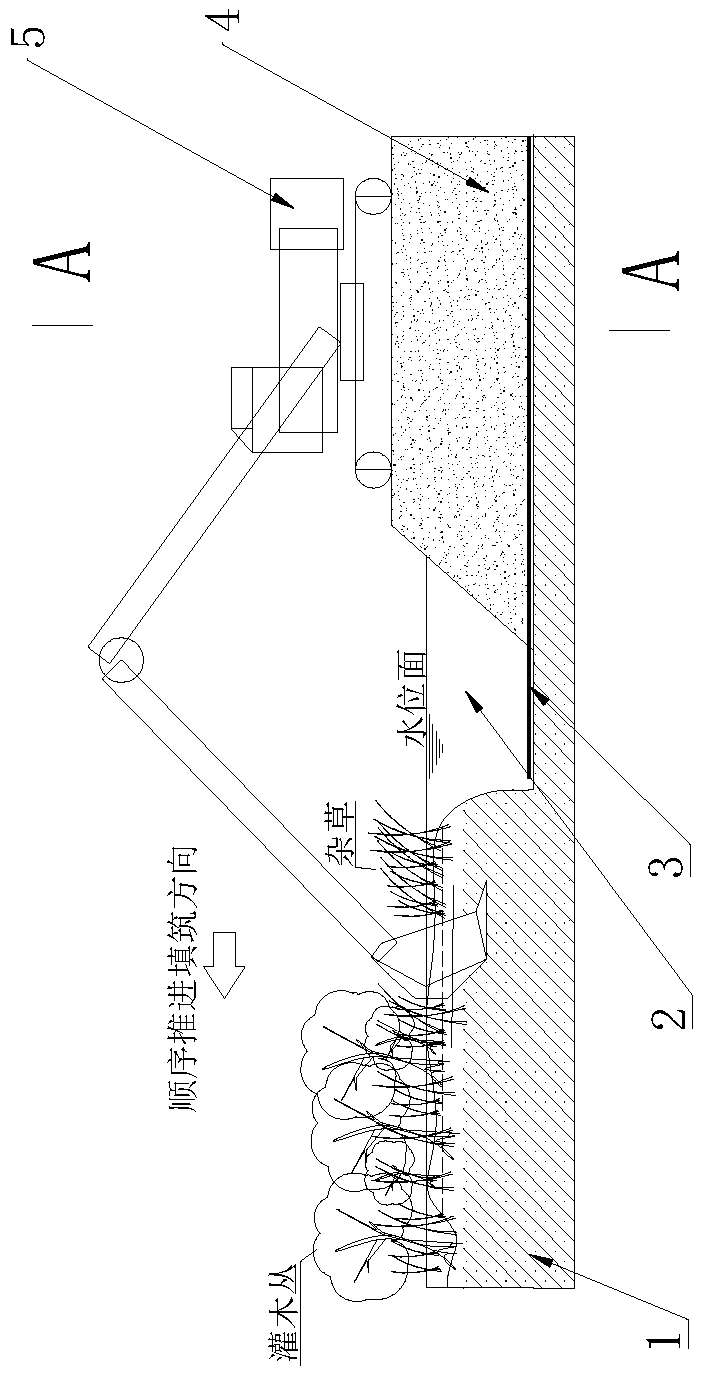

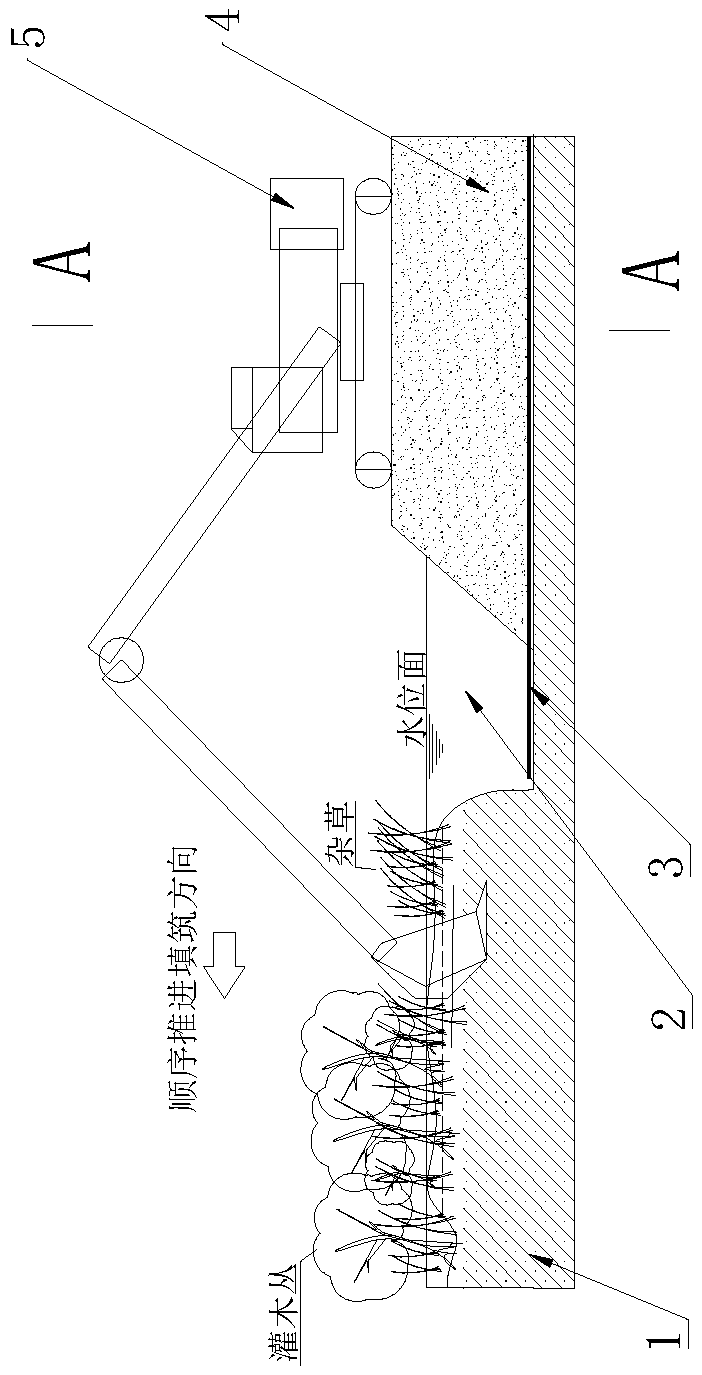

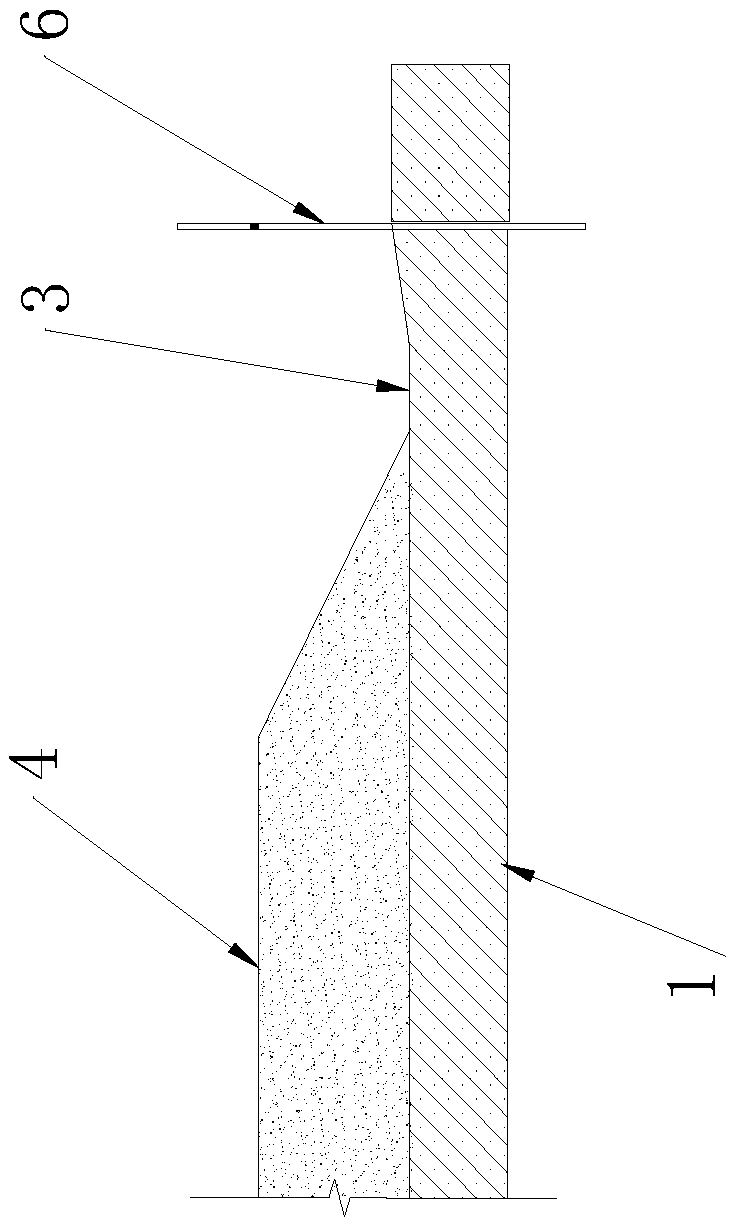

Pile-spanning waterproof heavy curtain combined pile side sleeve valve pipe grouting and water stopping construction method

InactiveCN108360542APouring position is accurateGood grouting plugging effectFoundation engineeringSleeve valveEngineering

The invention discloses a pile-spanning waterproof heavy curtain combined pile side sleeve valve pipe grouting and water stopping construction method. According to the key points of the technical scheme, the method comprises the following steps that a, surveying and setting out are conducted, specifically, the pile positions of slope protection piles are determined and marked, the positions of waterproof heavy curtains are determined and marked, and the slope protection piles and the waterproof heavy curtains are arranged alternately; b, holes are formed in the slope protection piles; c, reinforcement cages with sleeve valve pipes on the two sides are hoisted and placed; d, concrete is poured to form the slope protection piles, and pile body maintenance of the slope protection piles is conducted; e, the pile-spanning waterproof heavy curtains are constructed to form waterproof heavy curtain piles; f, the sleeve valve pipes on the two sides of the slope protection piles are subjected togrouting, plugging and reinforcing; and g, the waterproof heavy curtain piles are maintained. The purpose of conveniently filling leakage between the waterproof heavy curtains and the slope protection piles is achieved.

Owner:北京城建华夏基础建设工程有限公司

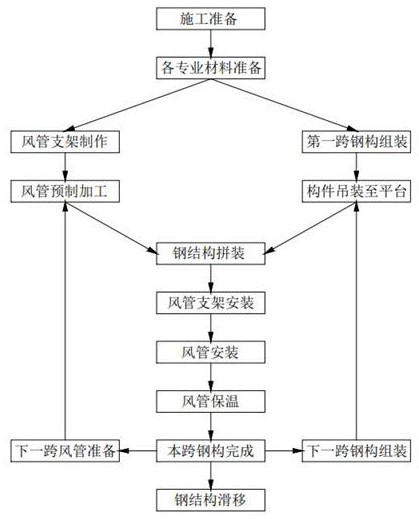

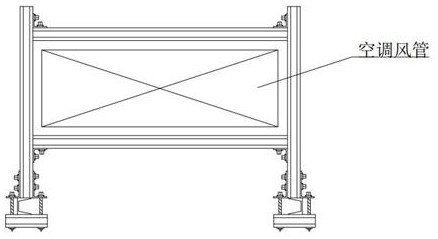

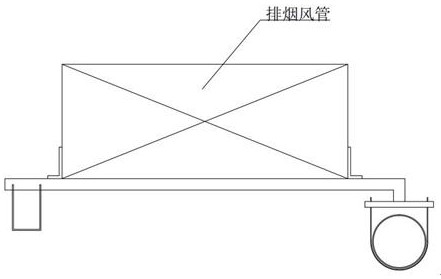

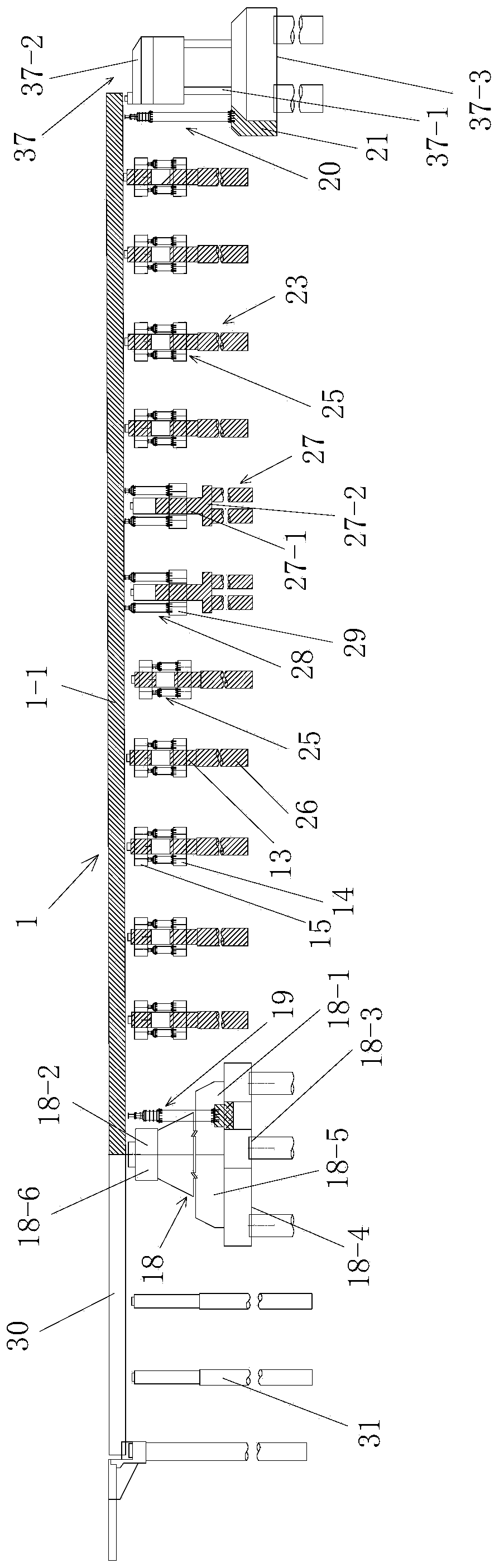

Roof steel structure and air duct synchronous sliding construction method

InactiveCN113565332AAvoid lifting difficultyImprove installation efficiencyBuilding material handlingArchitectural engineeringLong span

The invention relates to the technical field of supporting building facility construction. The method comprises the following construction steps that modeling is conducted on a whole system through BIM software, and the structure and position of an air duct are at least determined and at least comprise the size parameter and position information of the air duct and the structure and position information of a steel structure support; construction materials and devices are prefabricated according to data of a BIM model, and at least prefabrication machining of an air duct support and prefabrication machining of the steel structure support are included; a sliding rail and a sliding assembly platform are installed; the steel structure support is assembled, and ground assembling and hoisting of the steel structure support are included; the air duct support is installed, and the air duct is hoisted according to the air duct position information of the BIM model; and overall sliding is conducted. The steel structure support and the air duct are installed in a span-separated manner, each span is installed on the sliding assembly platform, then the steel structure support and the air duct overall slide to the sliding rail, the hoisting difficulty of large-span roof operation is avoided, and the installation efficiency and installation precision are improved through an information management system of the BIM.

Owner:CHINA CONSTR EIGHTH ENG DIV

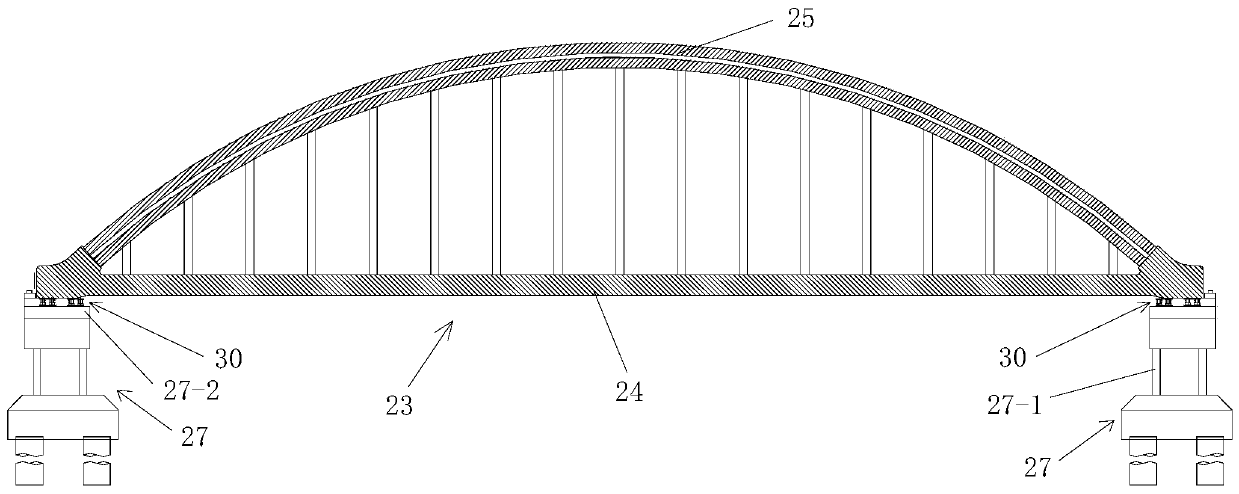

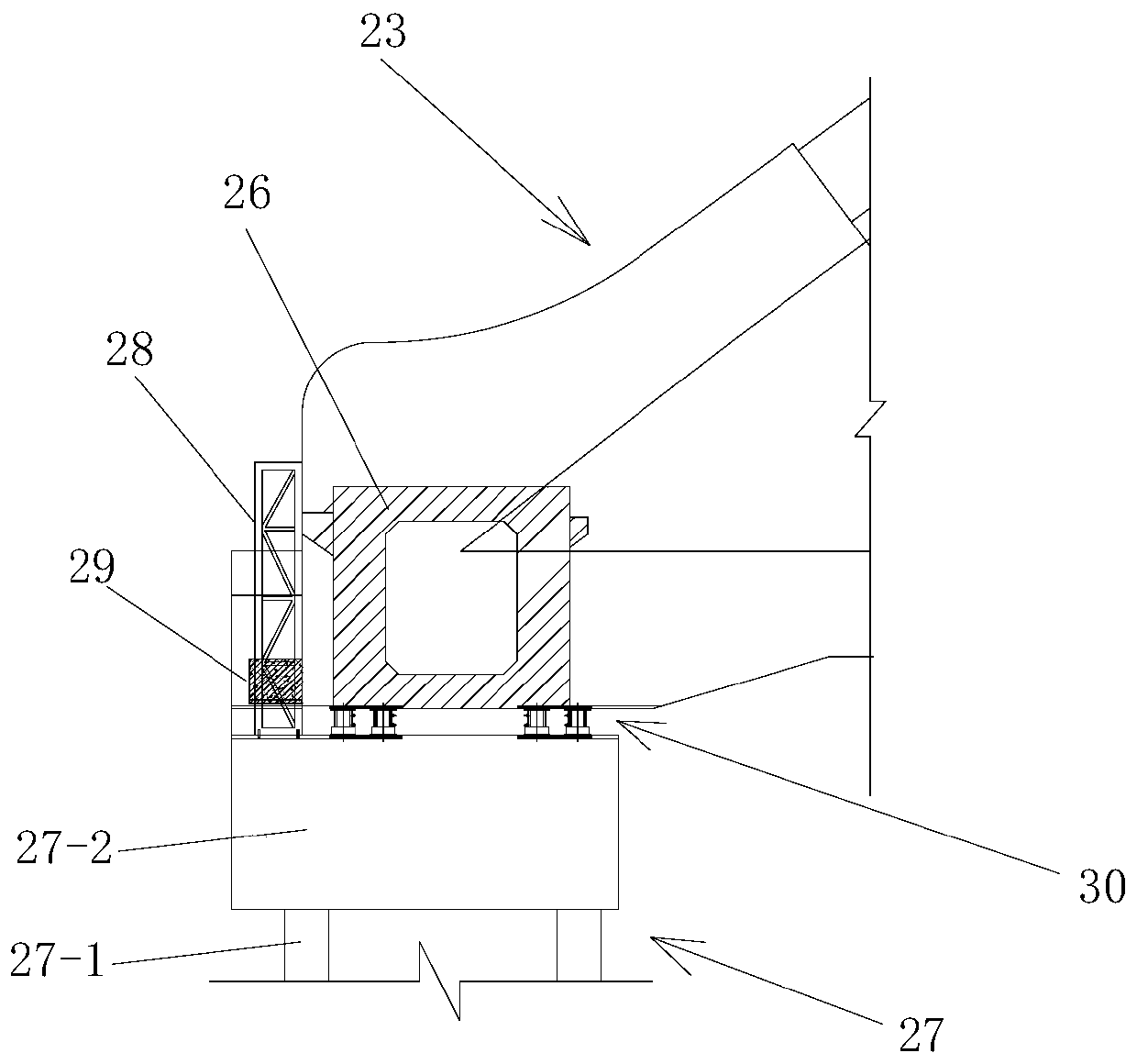

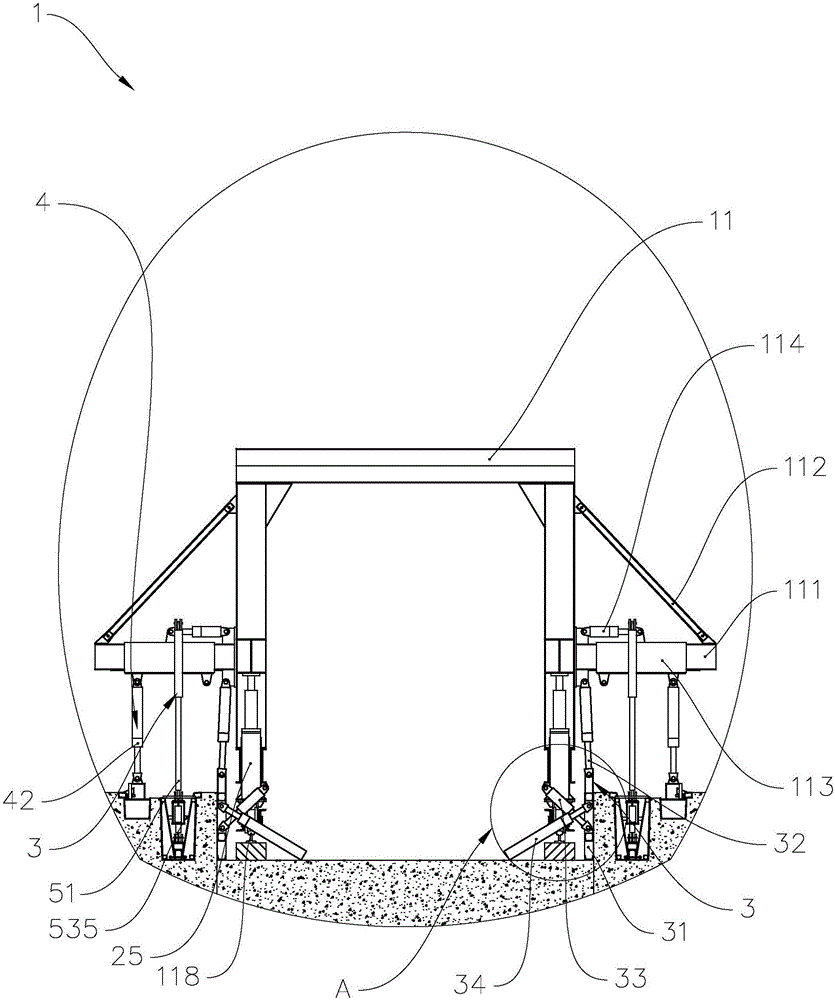

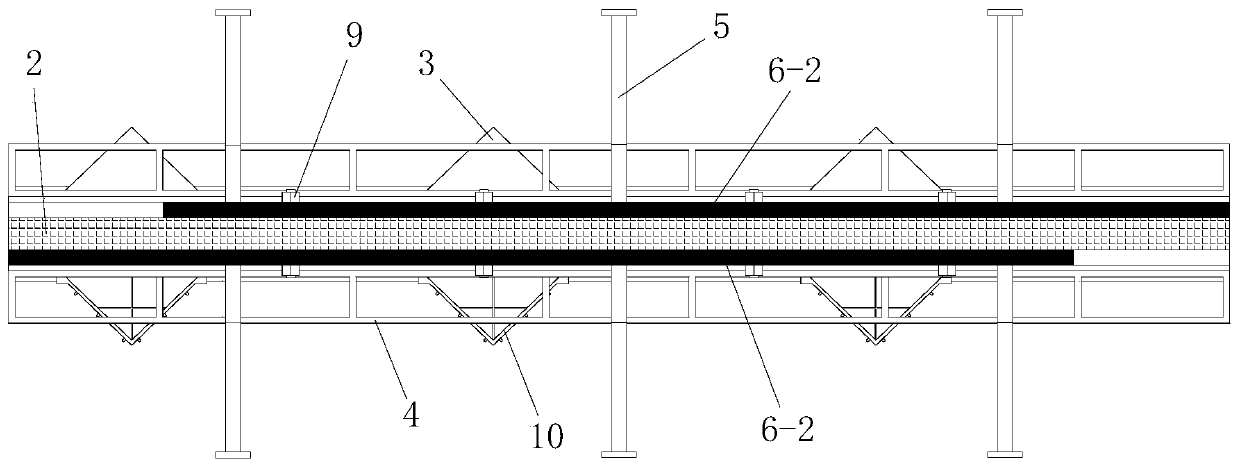

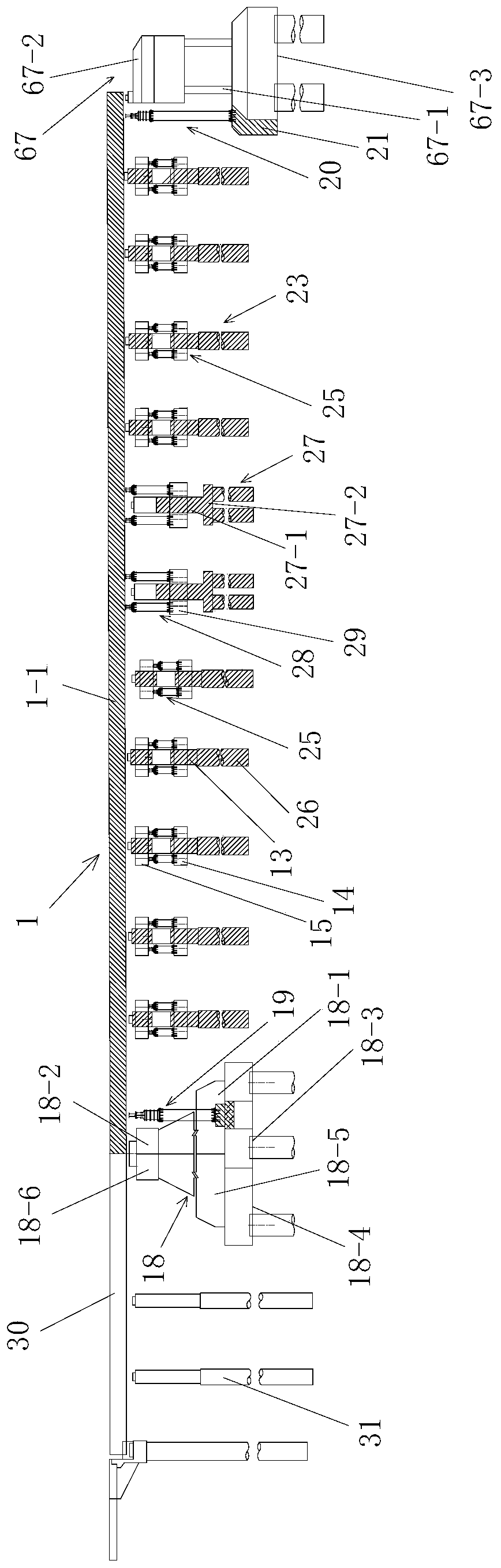

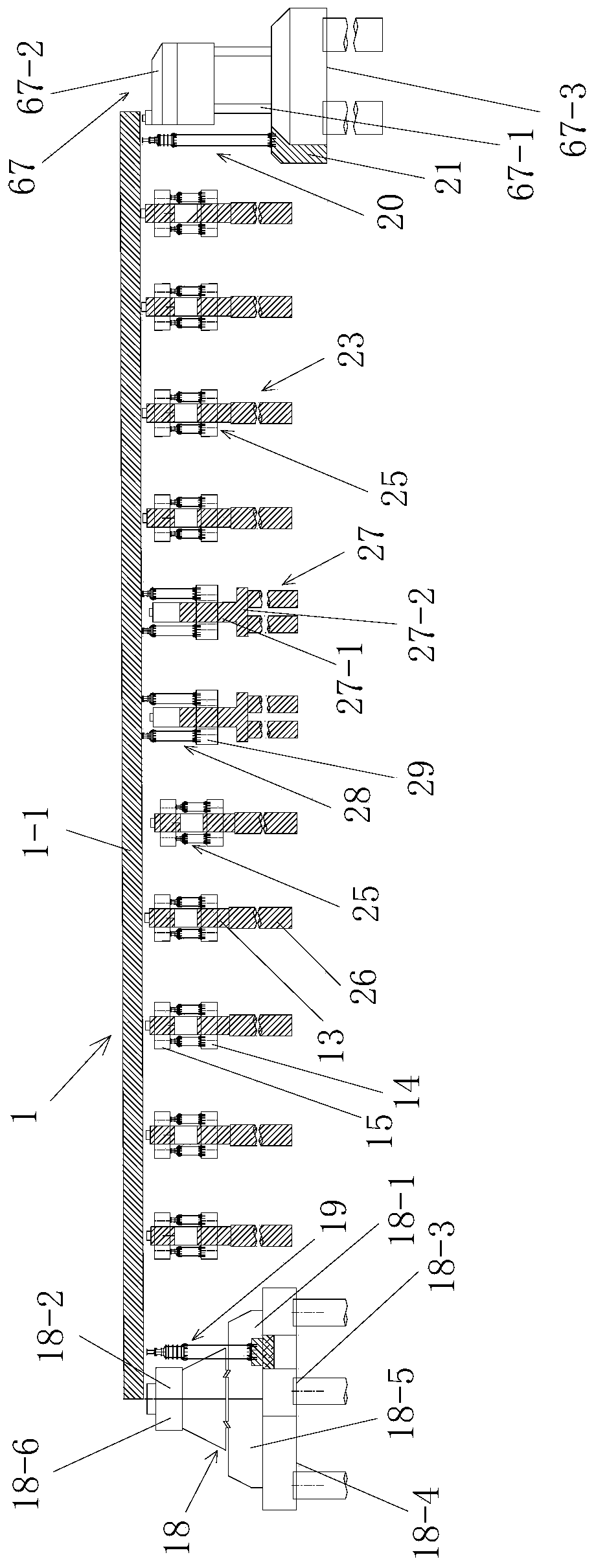

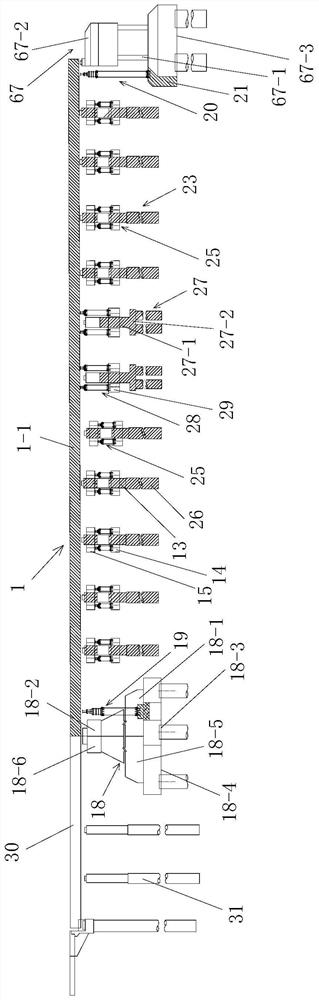

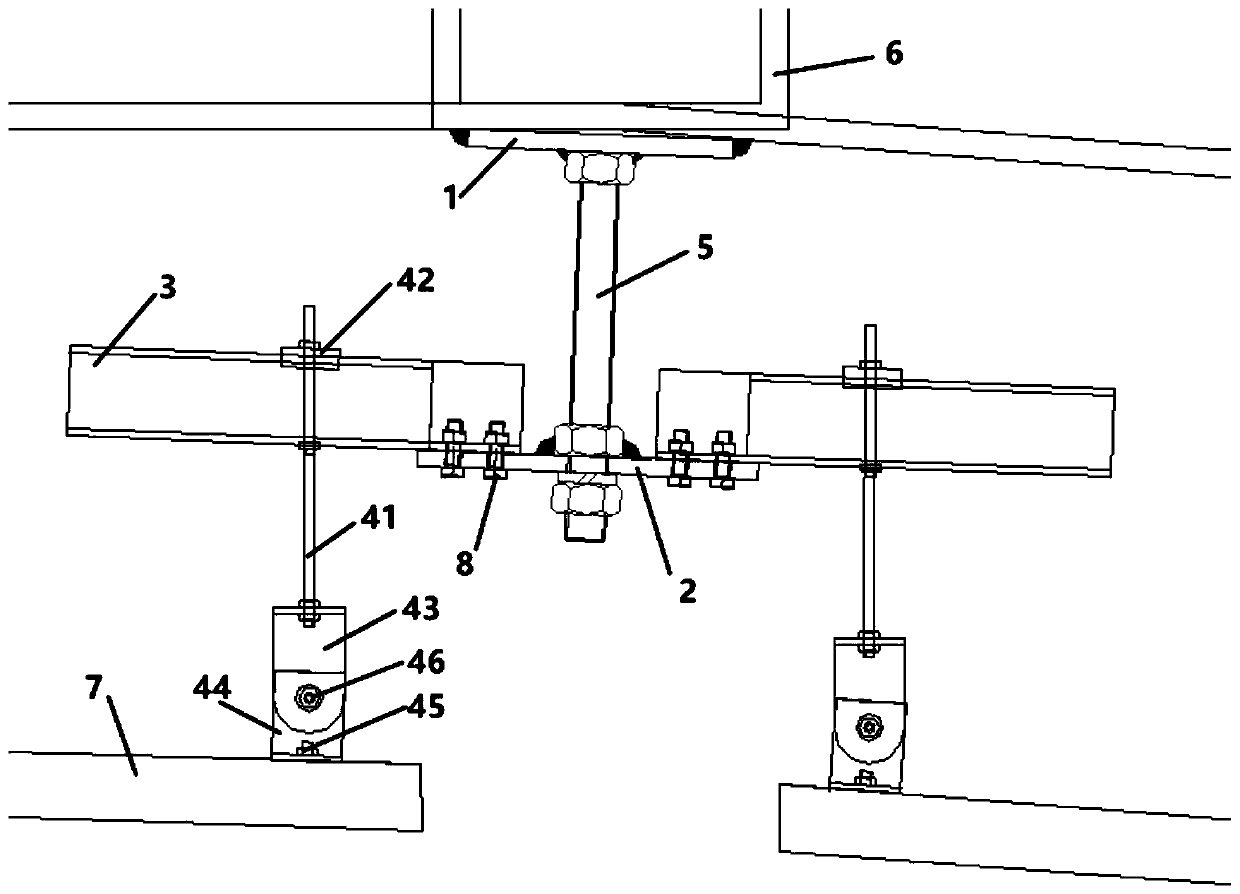

Large-span tie bar arch bridge approach bridge jacking system and jacking construction method

PendingCN110424246ASimple structureReasonable designBridge erection/assemblyArch-type bridgeStructural engineeringArch bridge

The invention discloses a large-span tie bar arch bridge approach bridge jacking system and jacking construction method. The system comprises a left approach bridge main beam jacking device and a right approach bridge main beam jacking device, wherein each of the approach bridge main beam jacking devices comprises an abutment-side hydraulic jacking device and a pier-side hydraulic jacking device,and each of both the abutment-side hydraulic jacking device and the pier-side hydraulic jacking device of each approach bridge main beam jacking device is an approach bridge beam end jacking device; and each of the approach bridge beam end jacking devices comprises a transverse distribution beam, a plurality of vertical jacking devices and a plurality of auxiliary supporting structures. The jacking construction method comprises the following steps of 1, mounting the jacking devices; 2, carrying out jacking; 3, increasing height of an approach bridge lower structure in a jointing way; and 4, removing the jacking devices. The large-span tie bar arch bridge approach bridge jacking system and jacking construction method have the advantages of reasonable structure design, simple and convenientconstruction and good use effect; the two left and right symmetrically-arranged approach bridge main beam jacking devices are adopted to carry out vertical jacking on a to-be-jacked approach bridge main beam, the vertical jacking devices and the auxiliary supporting structures are adopted in each approach bridge main beam jacking device to cooperate together to carry out jacking, and meanwhile theadopted temporary supporting structures have good bearing effect and good supporting stability, thus ensuring that the jacking process of the approach bridge main beam is stable and reliable.

Owner:NO 1 ENG LIMITED OF CR20G

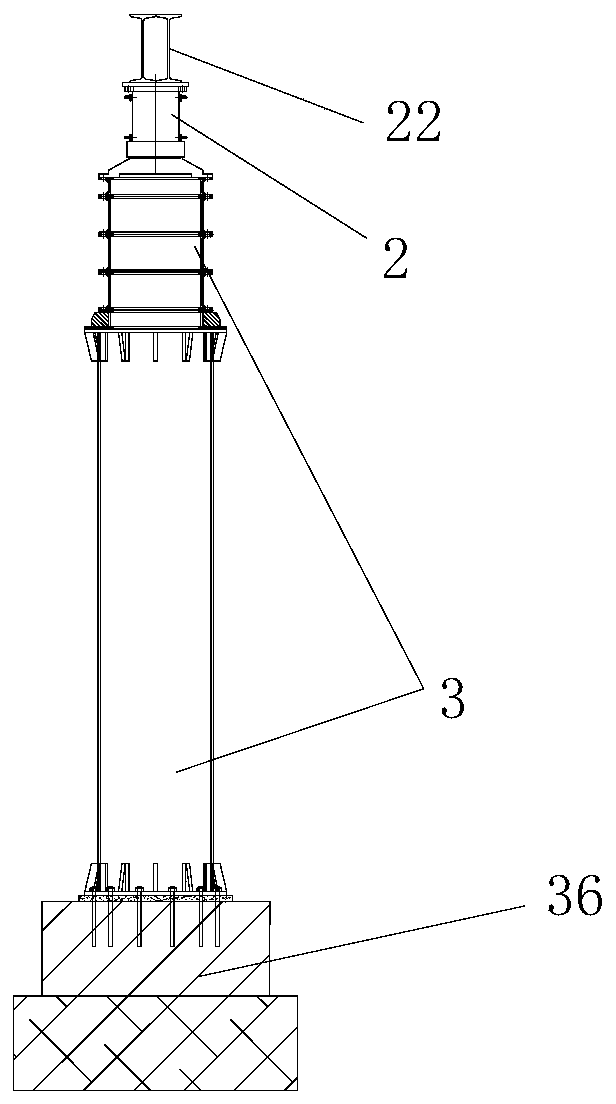

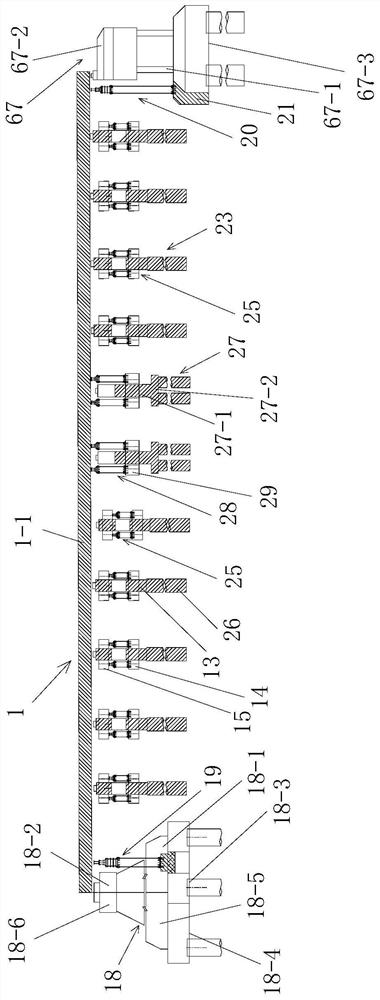

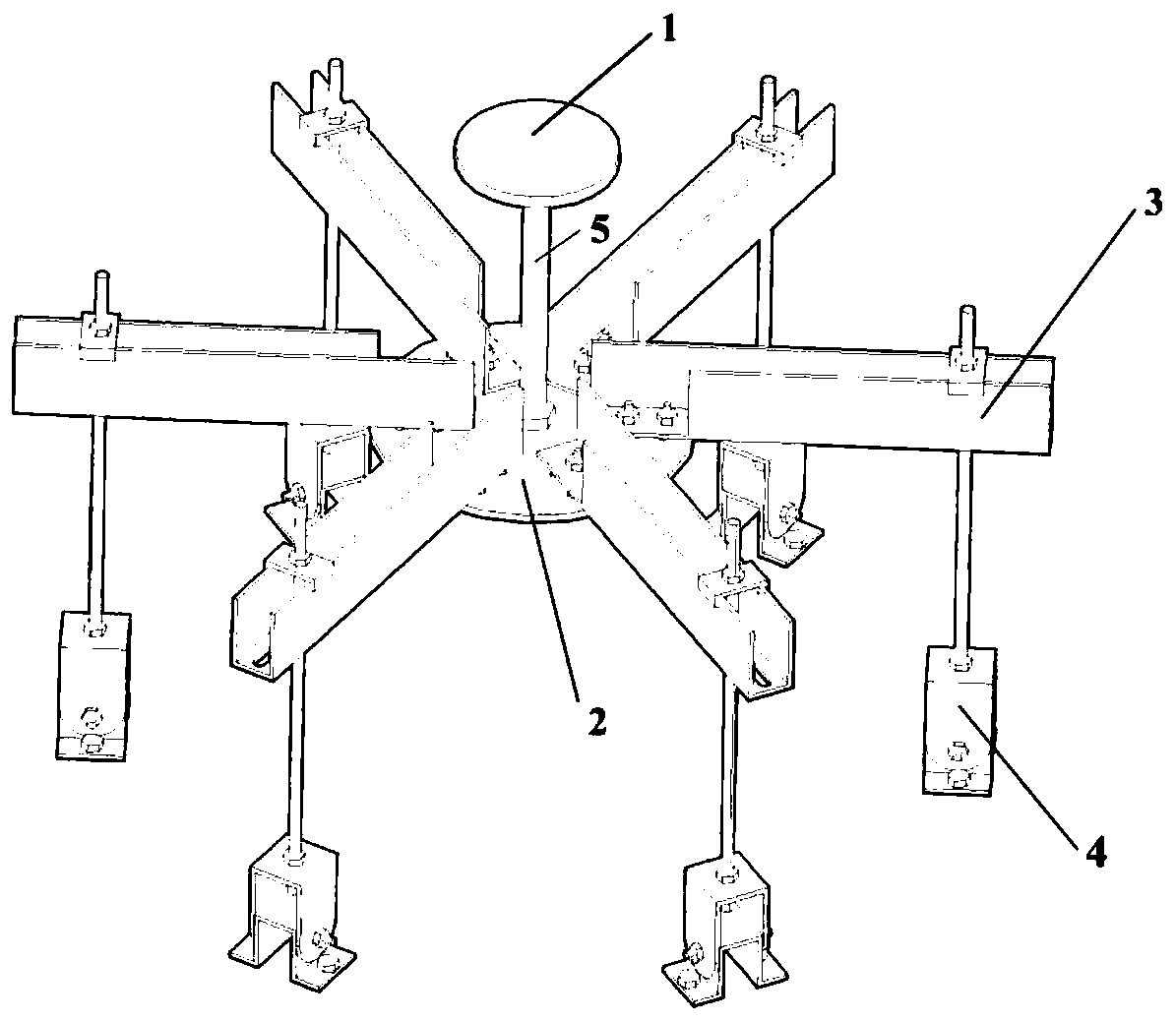

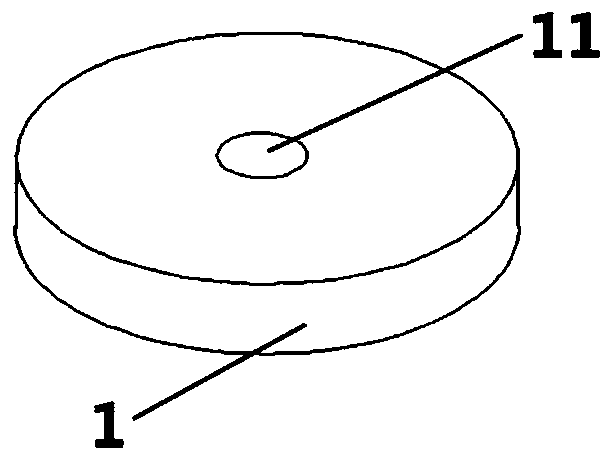

Jacking system for main bridge of large-span tied arch bridge and jacking construction method

PendingCN110424243ASimple structureReasonable designBridge erection/assemblyArch-type bridgeUltimate tensile strengthSubstructure

The invention discloses a jacking system for a main bridge of a large-span tied arch bridge and a jacking construction method. The system comprises a left main bridge jacking device and a right main bridge jacking device, wherein each arch bridge superstructure comprises a left arch bridge composite structure, a right arch bridge composite structure and multiple crossbeams, each arch bridge composite structure is a steel tube concrete tied arch and comprises a girder and an arch rib, and each main bridge jacking device is arranged under each arch bridge superstructure. The jacking constructionmethod includes the steps of firstly, jacking device installation; secondly, jacking; thirdly, jacking device disassembling; and fourthly, bridge substructure jointing. The system is reasonable in structural design, simple and convenient to construct and good in use effect, the left main bridge jacking device and the right main bridge jacking device which are arranged symmetrically are adopted for vertically jacking the bridge superstructures, vertical jacking devices and auxiliary supporting structures are adopted in the main bridge jacking devices to cooperate for jacking, multiple steel bar supporting cushion blocks are adopted to form a temporary supporting structure below a jack, the supporting strength is large, the bearing effect is good, and no dismantling is required in the laterperiod.

Owner:NO 1 ENG LIMITED OF CR20G +1

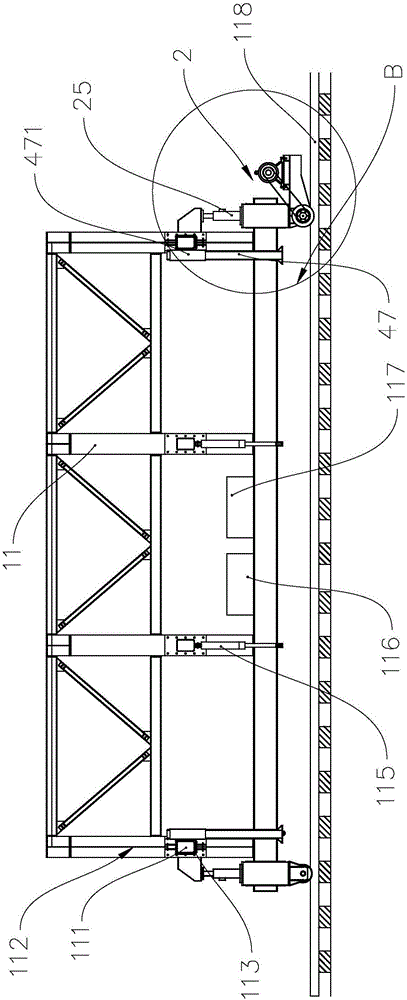

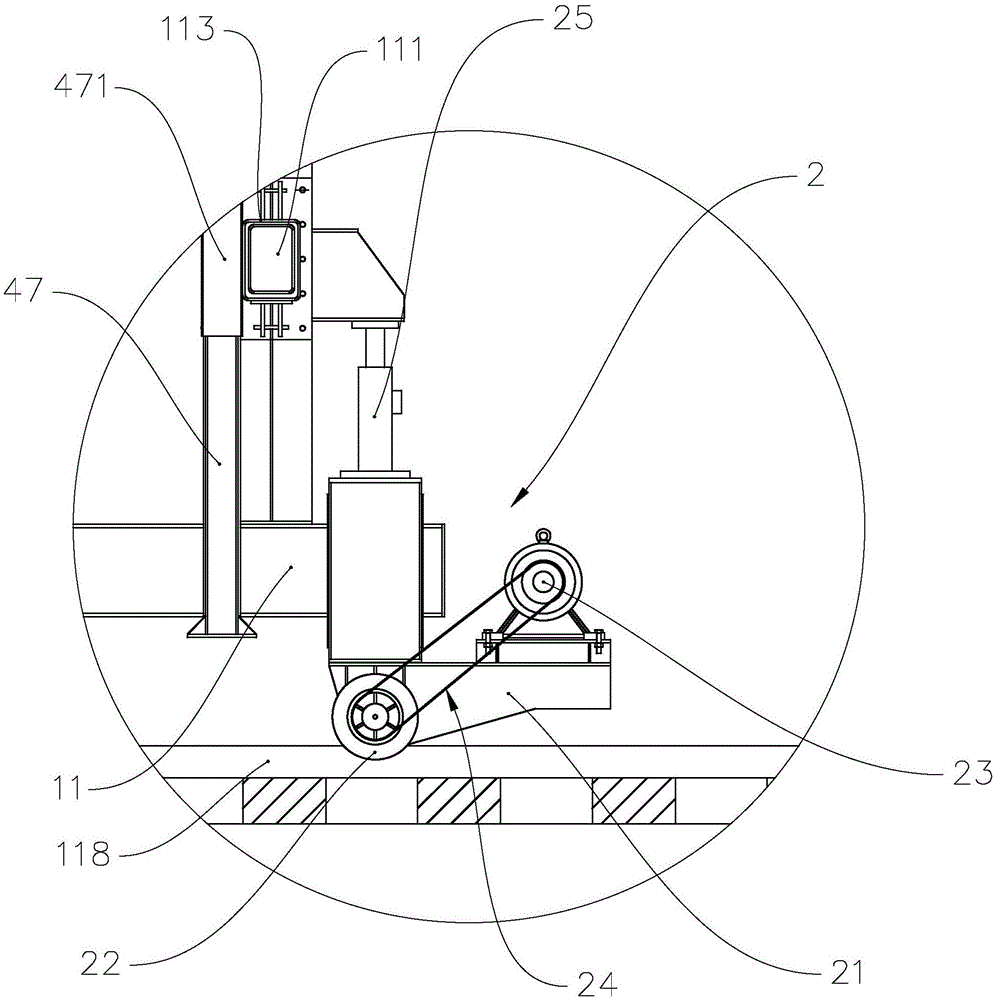

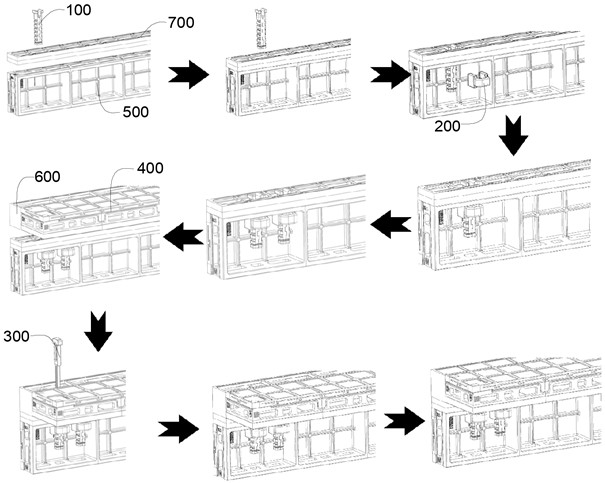

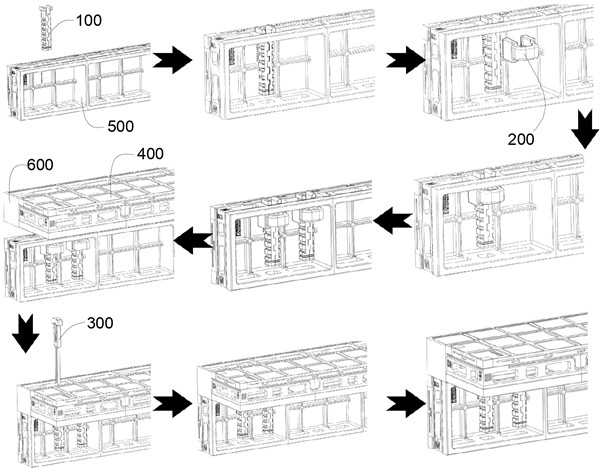

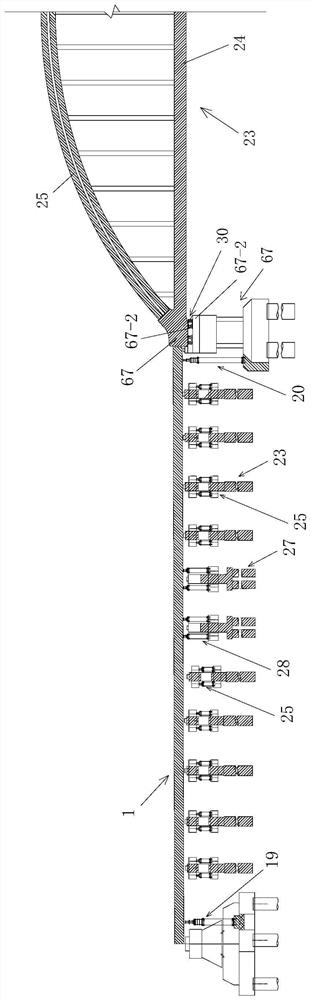

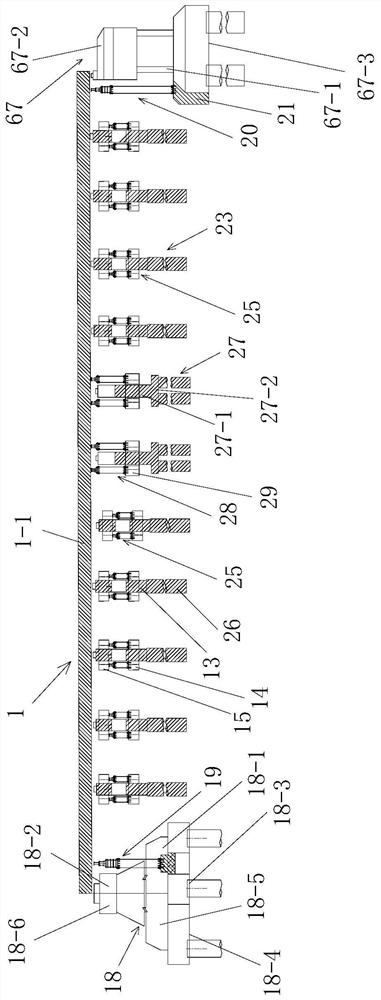

Tunnel ditch cable trough construction trolley

InactiveCN106089257AImprove construction qualityShort demoulding timeUnderground chambersDrainageDitchThreaded rod

The invention provides a tunnel ditch cable trough construction trolley which comprises a truss and a traveling system installed below the truss. The tunnel ditch cable trough construction trolley further comprises side wall die set devices, cable die set devices and ditch die set devices. Each side wall die set device comprises a side wall die set, a first oil cylinder and a second oil cylinder, wherein the two ends of the first oil cylinder are hinged to the side wall die set and the truss correspondingly, and the two ends of the second oil cylinder are hinged to the side wall die set and the truss correspondingly. Each cable die set device comprises a cable die set and a third oil cylinder, and the two ends of the third oil cylinder are hinged to the cable die set and the truss correspondingly. Each ditch die set device comprises a fourth oil cylinder, two oppositely arranged wedge-shaped die sets and an adjusting unit, wherein the adjusting unit comprises a bearing beam, an adjusting hand wheel and two oppositely arranged threaded rods, the two ends of the fourth oil cylinder are hinged to the truss and the bearing beam correspondingly, the adjusting hand wheel is arranged on the bearing beam, and each threaded rod is connected between the adjusting hand wheel and the corresponding wedge-shaped die set. The construction trolley has the advantages that the construction quality is high, and the demolding time is short.

Owner:NO 7 ENG CO LTD OF CHINA RAILWAY 19 BUREAU GRP +1

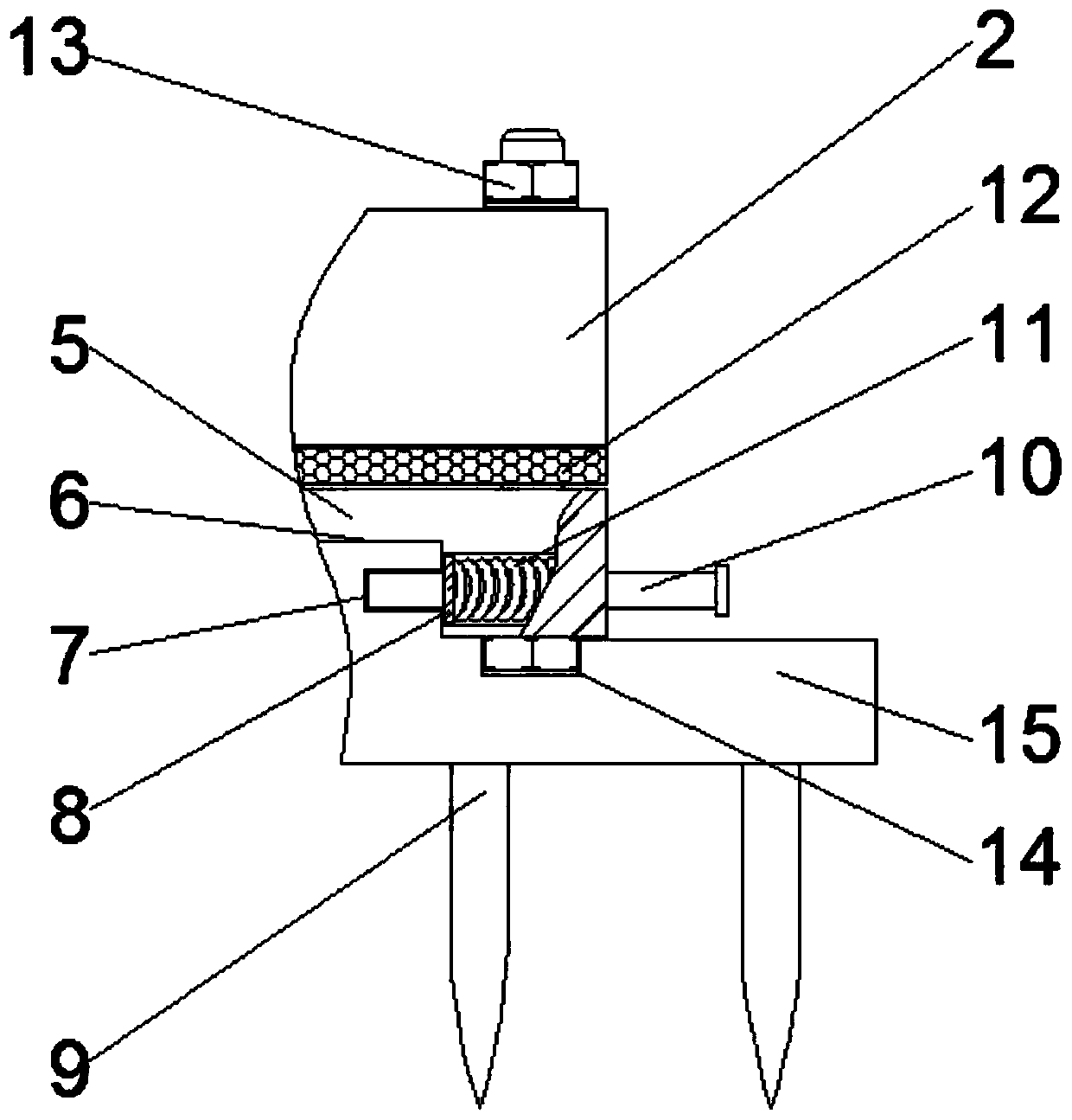

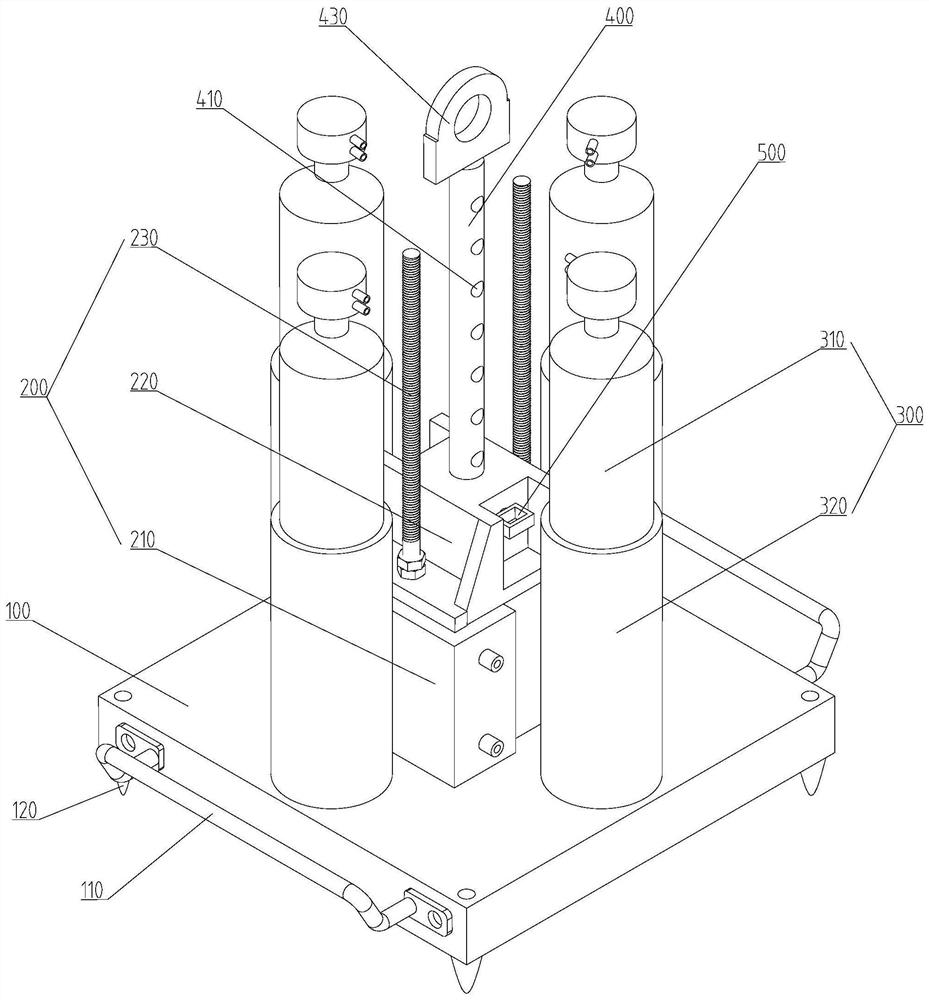

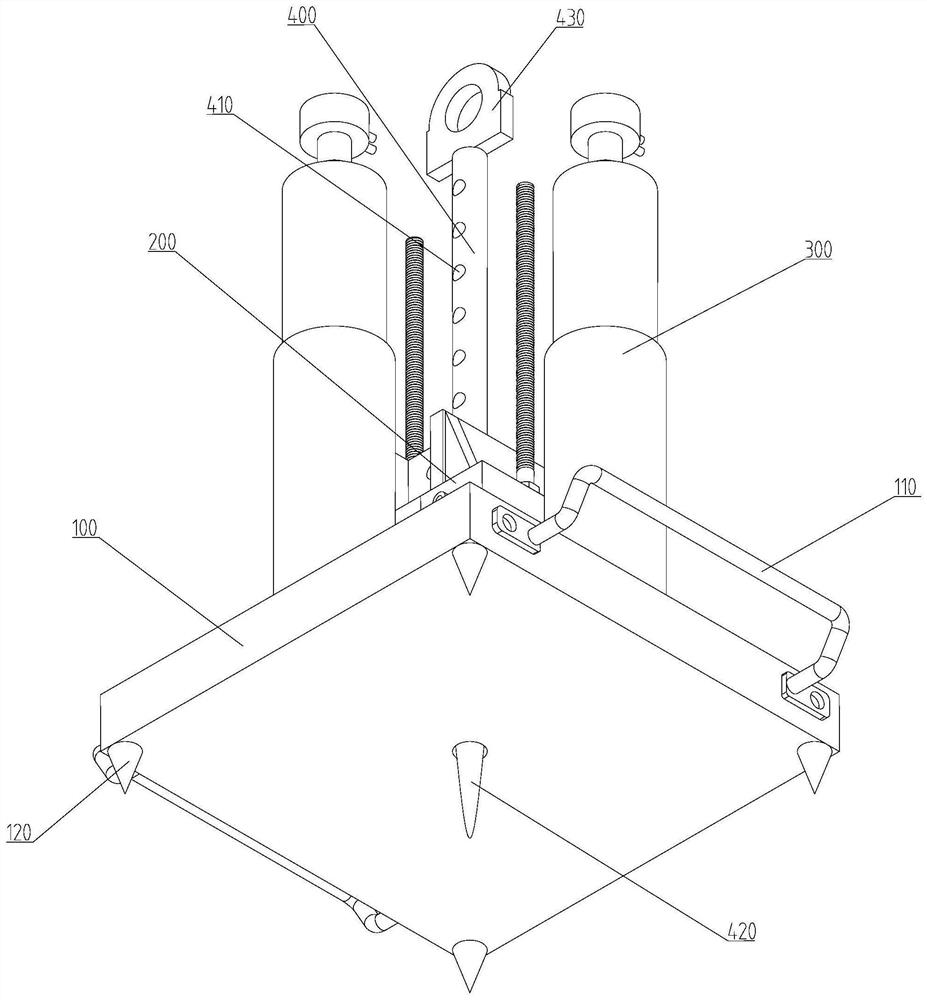

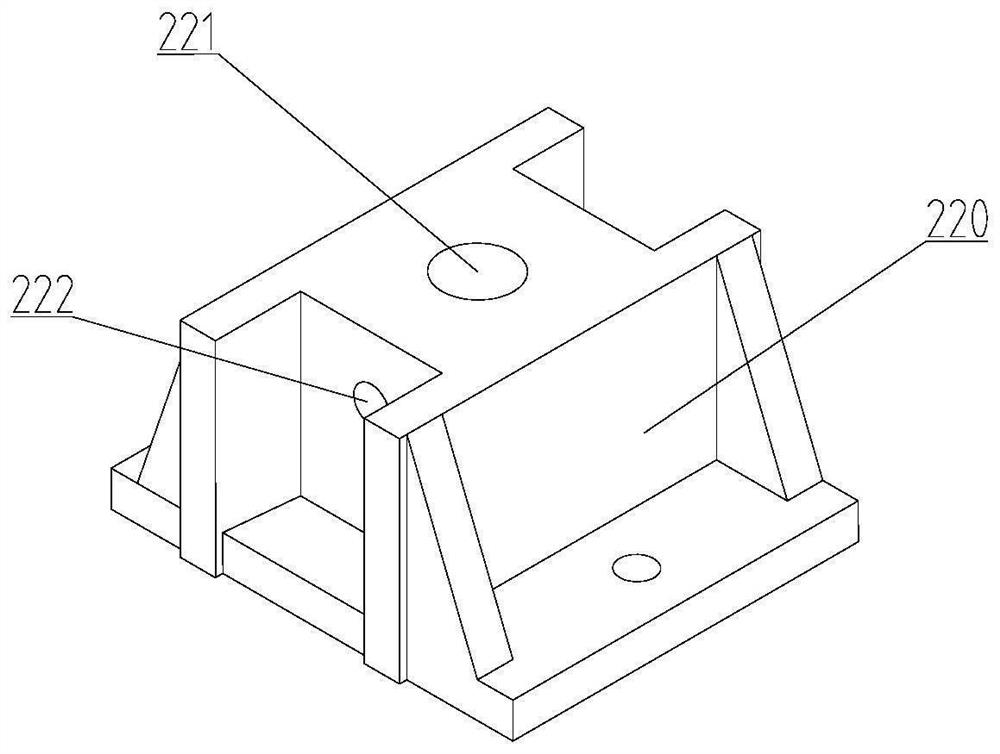

Automatic drilling machine

PendingCN109763775APrevents small drift situationsGuaranteed stabilityDerricks/mastsEngineeringSmall range

The invention discloses an automatic drilling machine, and relates to a geological prospecting drilling machine. The automatic drilling machine specifically comprises a drilling machine body, whereinantiskid mechanisms are mounted at the bottom ends of supporting legs on four sides of the drilling machine body; a square abutting groove is formed in the lower surface of a mounting seat; an upwardboss is integrally formed on the upper surface of a fixing plate and is rightly propped against an abutting groove in the lower surface of the mounting seat; and a groove in which a bolt is propped isformed in the upper surface of the fixing plate. According to the machine, the machine is are tightly inserted into the ground thorough inserting nails under a special geology condition, so that themachine body is greatly prevented from deviating in a small range due to the vibration, resulting in construction error in the drilling process; in addition, the stability of the supporting legs is ensured through the inserting nails, so that the stability of the drilling machine body is improved; and moreover, the mounting and dismounting are simple and quick; and meanwhile, parts on the drillingmachine bodies are blown with air to dissipate heat through a plurality of fans, so that the site working efficiency is ensured, and the safety of the site construction is ensured.

Owner:ANHUI UNIV OF SCI & TECH

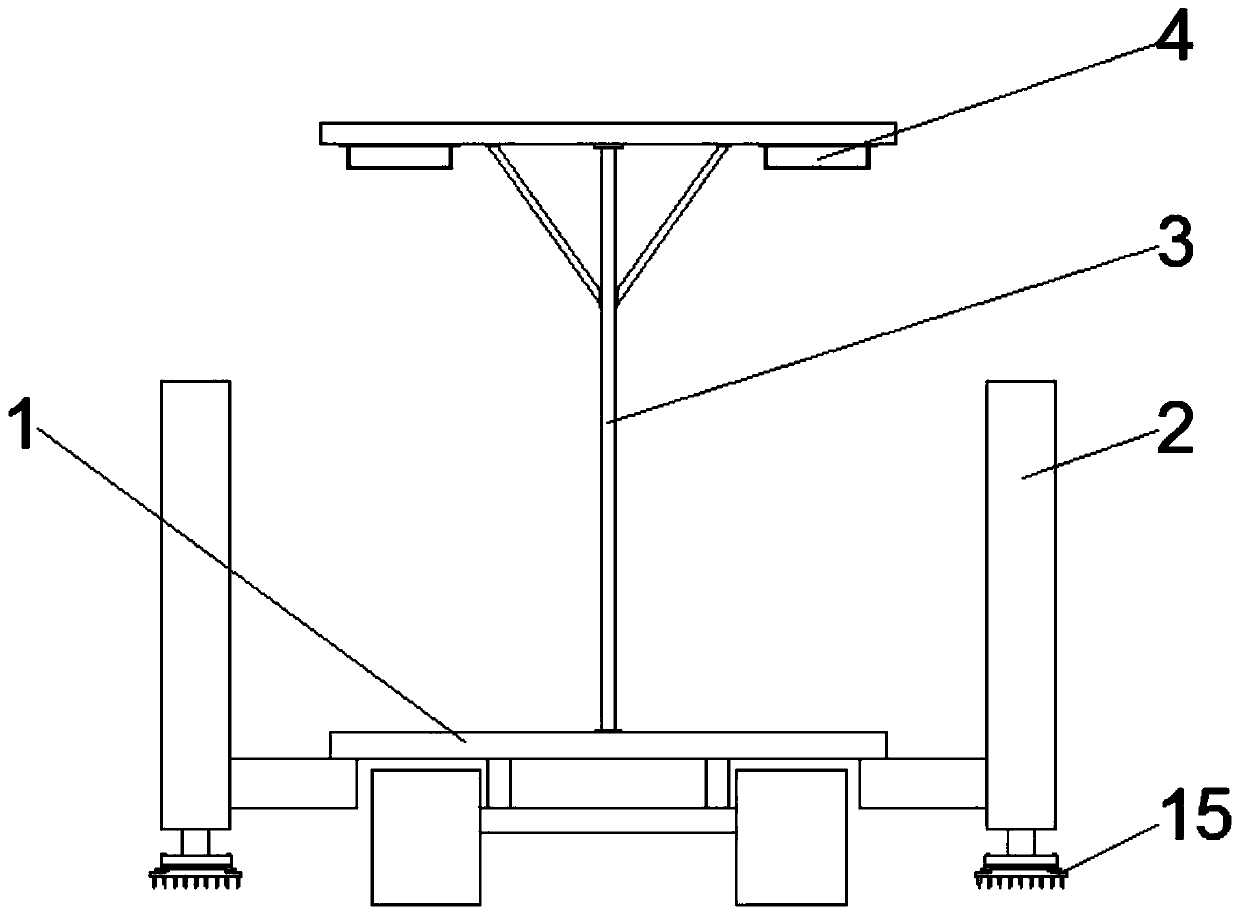

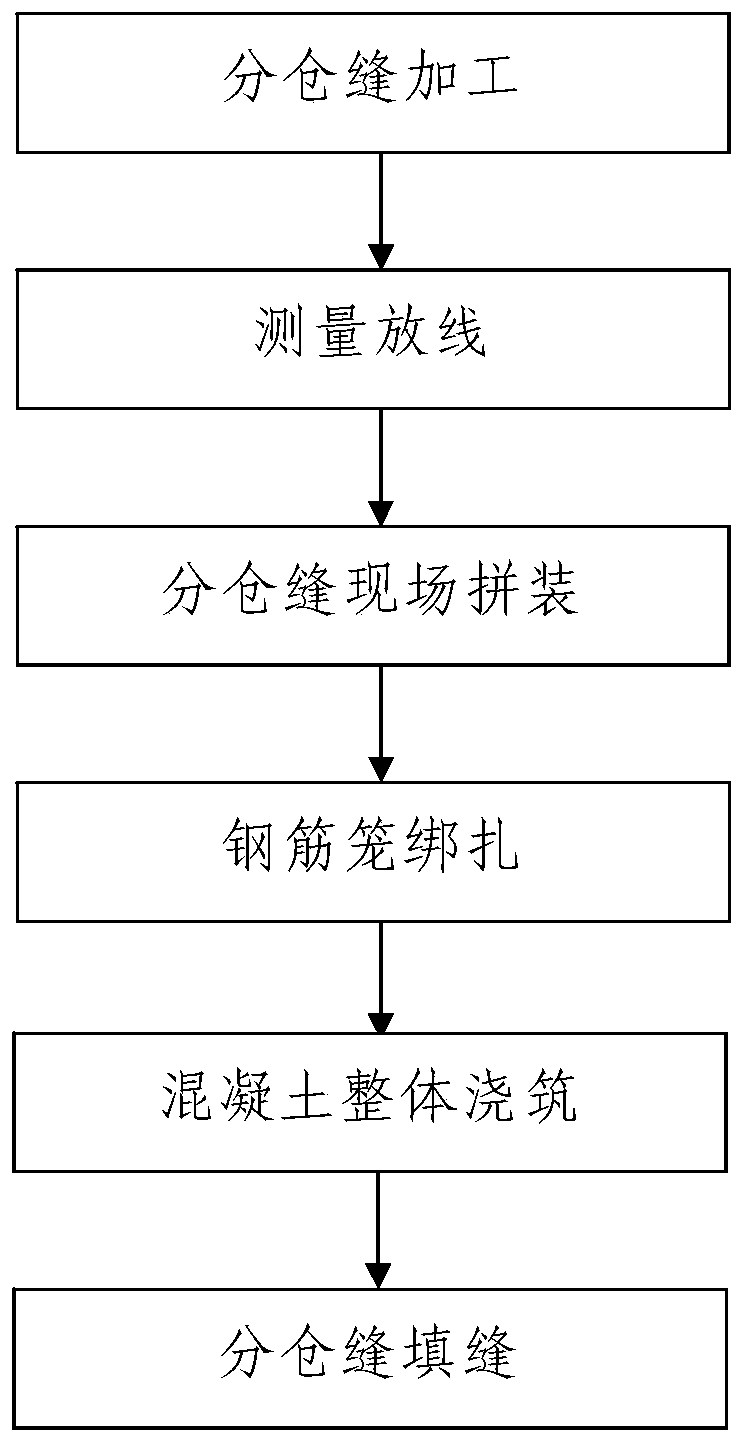

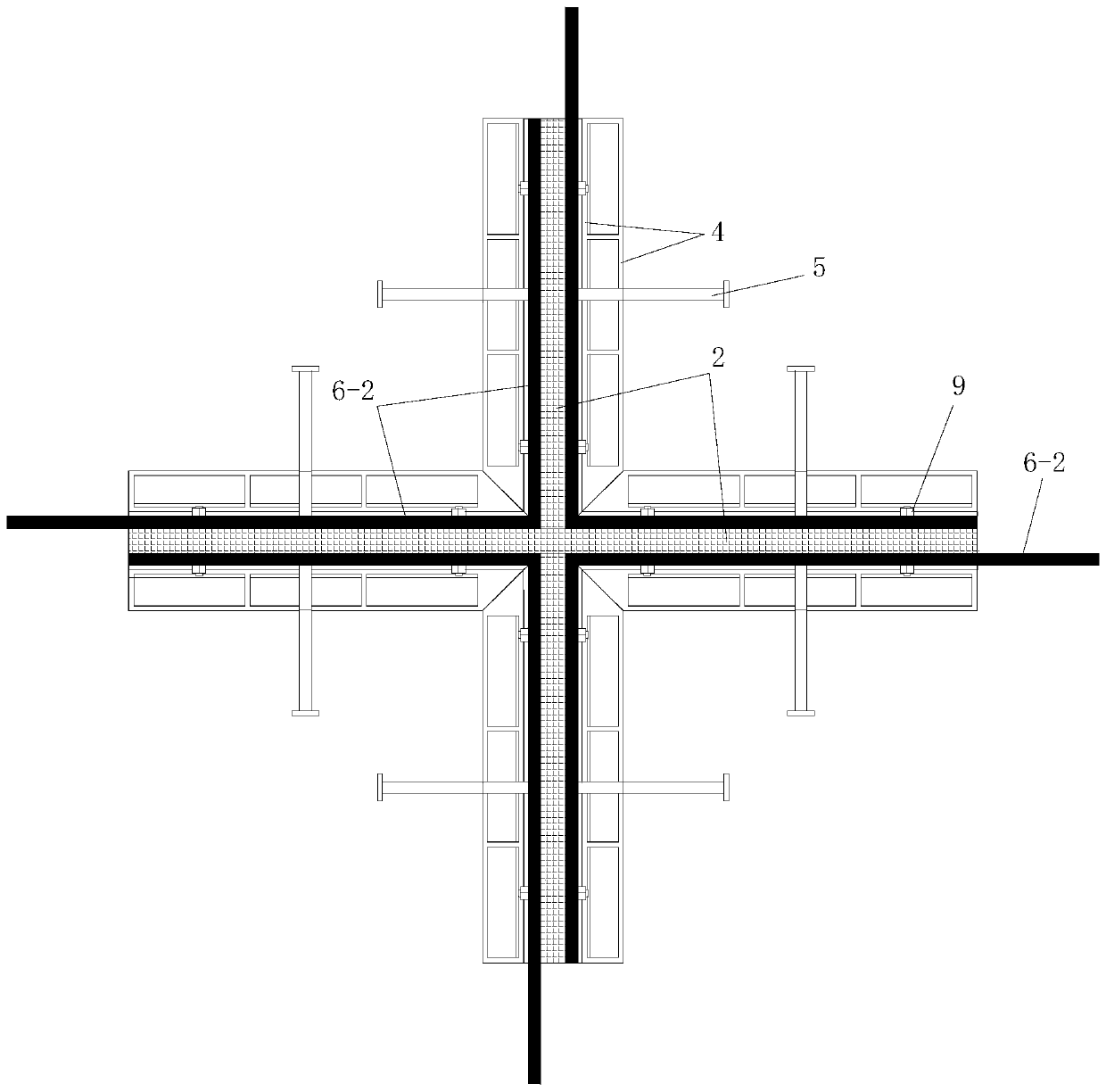

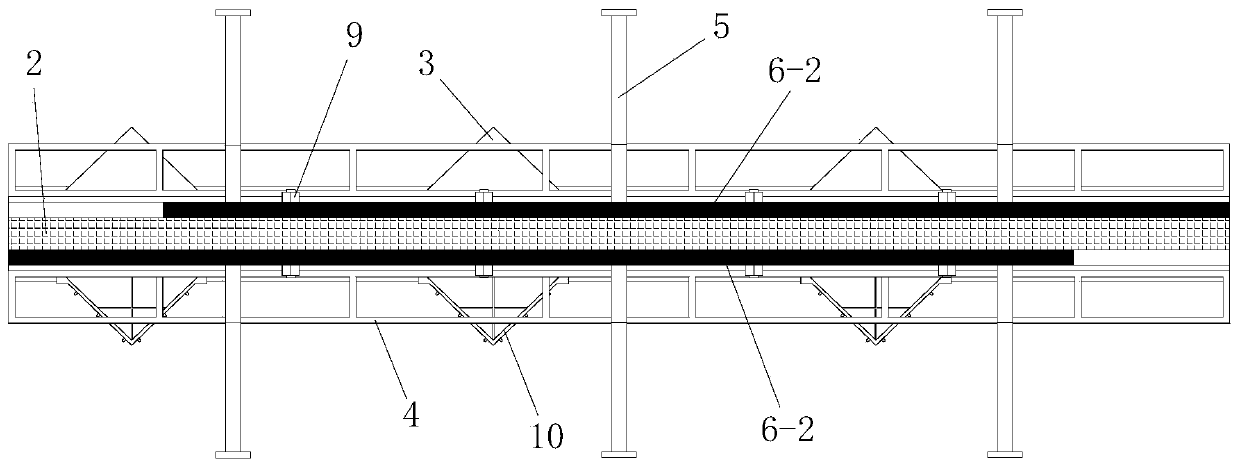

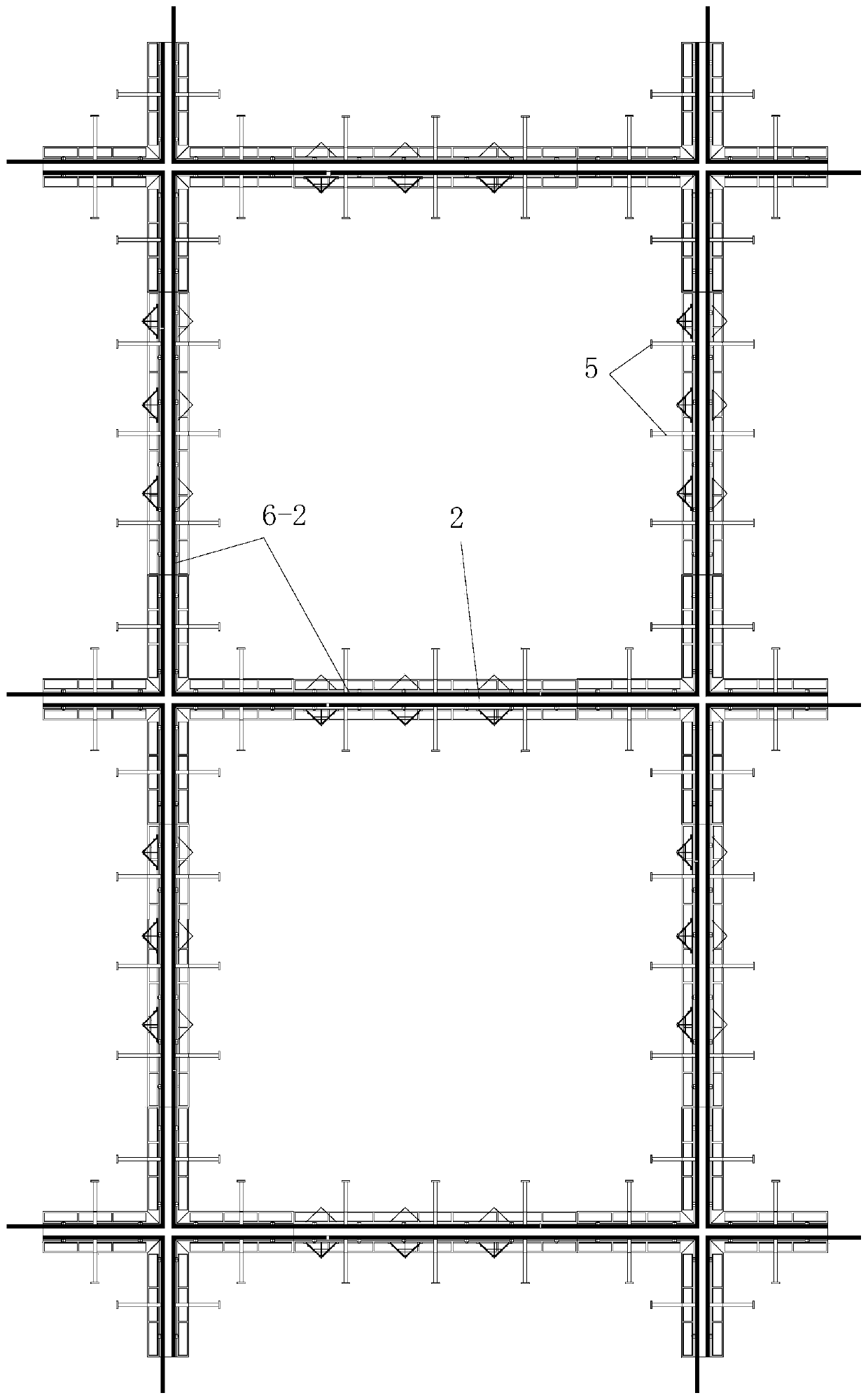

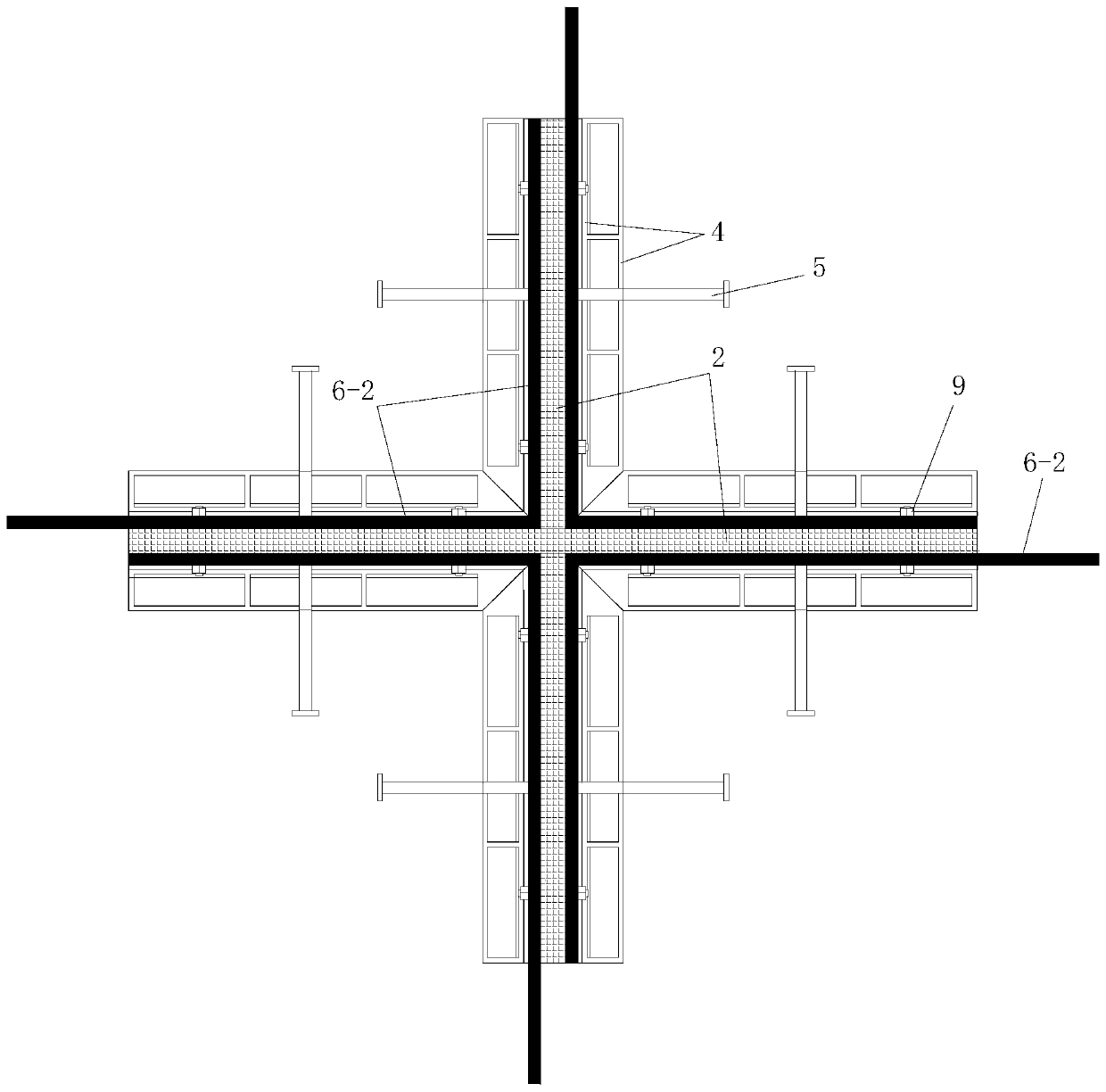

Construction method for partition seams of concrete floor

The invention discloses a construction method for partition seams of a concrete floor, wherein partition seam construction of the constructed concrete floor is conducted with integrated partition seams of galvanized plates; the integrated partition seams of the galvanized plates comprise on-spot spliced partition seams made through splicing of multiple flat and straight partition seams and multiple crossed partition seams; and the partition seam construction of the constructed concrete floor comprises the steps of (1) processing of the partition seams, (2) measurement and setting out, (3) on-spot splicing of the partition seams, (4) binding of reinforcement cages, (5) overall pouring of concrete and (6) seam filling of the partition seams. The method disclosed by the invention has the beneficial effects that the on-spot spliced partition seams are completed through on-spot slicing of the flat and straight partition seams and the crossed partition seams which are processed and formed inadvance; the flat and straight partition seams and the crossed partition seams have rational design and good use effects; and problems such as a long construction period, poor use effects, low resistance to frost heaving and failure to guarantee construction equality during existing partition seam construction of large-area concrete floors can be solved effectively.

Owner:陕西建工集团股份有限公司

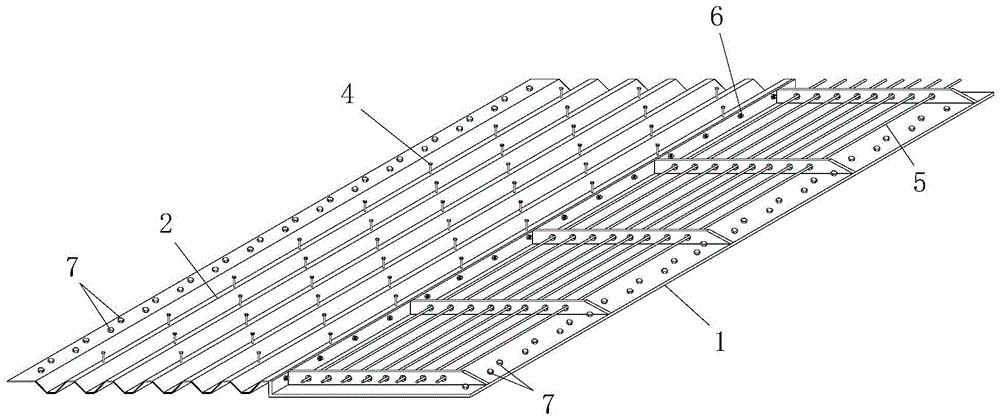

Galvanized plate integrated dividing joint and construction method

The invention discloses a galvanized plate integrated dividing joint. A plurality of straight dividing joints and a plurality of cross-shaped dividing joints are adopted to be assembled into an onsiteassembled dividing joint, independent dividing joints adopted in the straight dividing joints and the cross-shaped dividing joints are galvanized plate dividing joints, and the two sides of the straight dividing joints are provided with force transmission steel plates. The galvanized plate integrated dividing joint is reasonable in structural design and good in using effect, and the problems thatin the prior art, during existing large-area concrete terrace dividing joint construction, the construction period is long, the using effect is poor, the frost heaving resistance is low, and the construction quality is unlikely to be ensured can be effectively solved. Meanwhile, the invention further discloses a method for constructing the concrete terrace through the galvanized plate integrateddividing joint. The method comprises the steps of 1, dividing joint machining, 2, surveying and setting out, 3, dividing joint onsite assembling, 4, reinforcement cage binding, and 5, concrete overallpouring. The method is simple, design is reasonable, the construction efficiency is high, the construction period is short, and the construction quality can be effectively ensured.

Owner:陕西建工集团股份有限公司

Large-span tie bar arch bridge transformation method based on bridge hydraulic jacking system

ActiveCN110424245AReasonable structural designEasy to installBridge erection/assemblyBridge strengtheningArch bridgeBuilding construction

The invention discloses a large-span tie bar arch bridge transformation method based on a bridge hydraulic jacking system. A bridge to be transformed comprises a main bridge and two approach bridges.In terms of the transformation of the bridge to be transformed, the transformation method comprises the following steps of 1, carrying out bridge jacking and construction on the newly-built approach bridges, and specifically carrying out jacking construction on a to-be-jacked bridge upper structure of the bridge to be transformed and to-be-jacked approach bridge main beams 1 of the two approach bridges through the bridge hydraulic jacking system; and 2, carrying out subsequent construction. The method has the advantages of being reasonable in design, simple and convenient in construction and good in use effect; jacking for the main bridge and jacking for the two approach bridges are carried out correspondingly, structures and arrangement positions of an approach bridge jacking system and amain bridge jacking system which are adopted are specifically limited, thus being capable of conveniently and rapidly completing the jacking construction process of the large-span arch bridge, and the jacking process is safe and reliable; and in addition, while jacking is carried out on the original bridge upper structure, the two approach bridges on the front and rear portions are newly constructed so that backfilling workload can be effectively reduced, and the construction period can be shortened as well.

Owner:NO 1 ENG LIMITED OF CR20G

Construction method of operation platform for construction in deep and thick peat soil area

ActiveCN109083122AImprove bearing capacityGuaranteed uptimeRoadwaysSoil preservationPeatArchitectural engineering

The invention provides a construction method of an operation platform for construction in a deep and thick peat soil area. The construction method comprises the following steps that D, within the range of a machine arm of an excavation machine, a roadbed trough is excavated; E, geotechnical cloth is laid on the bottom of the roadbed trough; F, sea sand is filled back into the roadbed trough, and aprimary platform is formed; G, the excavation machine is moved to the primary platform obtained in the former step; and H, the steps from D to G are repeated until all primary platforms in the construction area are completed, wherein in the step H, every time after the primary platform of a certain distance length is completed, the sea sand is filled back above the primary platforms and compacted, and the operation platform for construction is formed. According to the construction method, permeable performance and reinforced performance of sea sand resources and the geotechnical cloth are fully utilized, the bearing ability of the base is enhanced, it is ensured that equipment comes in and out of a site and operates normally, the construction error of the mechanical equipment due to uneven settlement is avoided, and the reliable guarantee is provided for construction of follow-up foundation treatment.

Owner:CHINA MCC20 GRP CORP

A method for installing a contact rail channel of a magnetic levitation track beam and a channel positioning mold thereof

ActiveCN105463958BEnables parallel installationAchieve installationRailway track constructionArchitectural engineeringMagnetic levitation

The invention relates to the field of track construction and in particular relates to an installation method for conduits of contact rails of magnetism suspension track beams and a positioning mold for the conduits. The method comprises the following steps: manufacturing the positioning mold for the conduits of the contact rails of the track beams; positioning and perforating side formworks of beam boxes; fixing conduit groups; pouring concrete; and dismantling the formworks. The positioning mold for the conduits of the contact rails of the track beams is used for assembling and grouping to enable the parallel construction error of double conduit groups to meet the design requirement; conduit positioning holes formed in external steel formworks of the track beams can enable the deflection construction error of the conduits to meet the design requirement and can also avoid mortar leakage during concrete pouring; and T-shaped bolts on the conduits are connected with the external steel formworks through the positioning holes, the insides of the T-shaped bolts are connected with the conduits, and nuts are tightened to ensure that indentations are tightly jointed with the conduits, thereby eliminating the embedded construction error of the conduits and the oblique construction error of the double conduit groups, ensuring the construction quality of the conduits and ensuring the installation accuracy of the conduits.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

Bridge Deck Seamless Expansion Device and Its Construction Method Based on Stiffened Slabs

InactiveCN104674650BWell formedSimple structureBridge structural detailsBridge erection/assemblyWave shapeBridge deck

The invention discloses a stiffened joint-crossing plate based bridge deck jointless expansion device and a construction method thereof. The expansion device comprises a prefabricated expansion assembly and an expansion joint filler filled layer filled above the prefabricated expansion assembly, wherein the prefabricated expansion assembly is arranged on an expansion joint reserved between every two adjacent girder segments, and a sliding layer is laid on a girder exposed segment of each girder segment; the prefabricated expansion assembly comprises a stiffened joint-crossing plate and two wave-shaped expansion plates. A construction method for an expansion device to be repaired comprises the steps of cleaning an original bridge expansion device, constructing reserved mounting grooves, constructing the sliding layers, carrying out field assembly and mounting on the prefabricated expansion assembly and constructing the expansion joint filler filled layer. A construction method for an expansion device to be constructed comprises the steps of prefabricating the prefabricated expansion assembly, carrying out field assembly on the prefabricated expansion assembly, constructing the sliding layers, mounting the prefabricated expansion assembly and constructing bridge deck pavement structures and the expansion joint filler filled layer. The stiffened joint-crossing plate based bridge deck jointless expansion device and the construction method thereof have the advantages that the design is reasonable, the construction is convenient, the use effect is good, and multiple problems of the existing expansion devices can be solved.

Owner:XIAN HIGHWAY INST

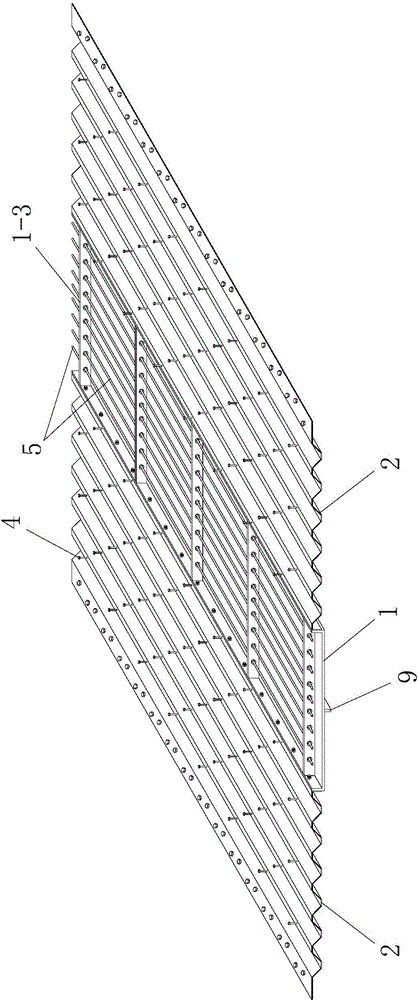

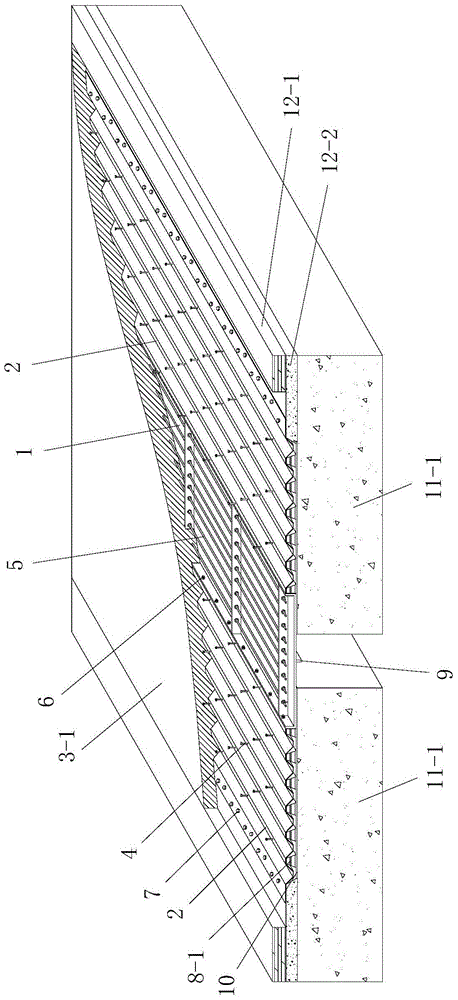

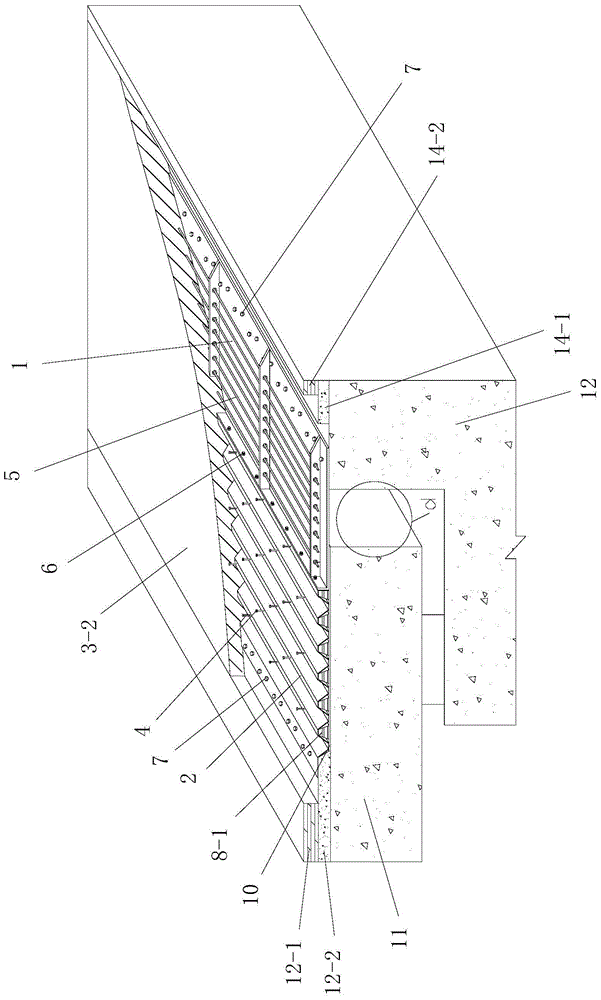

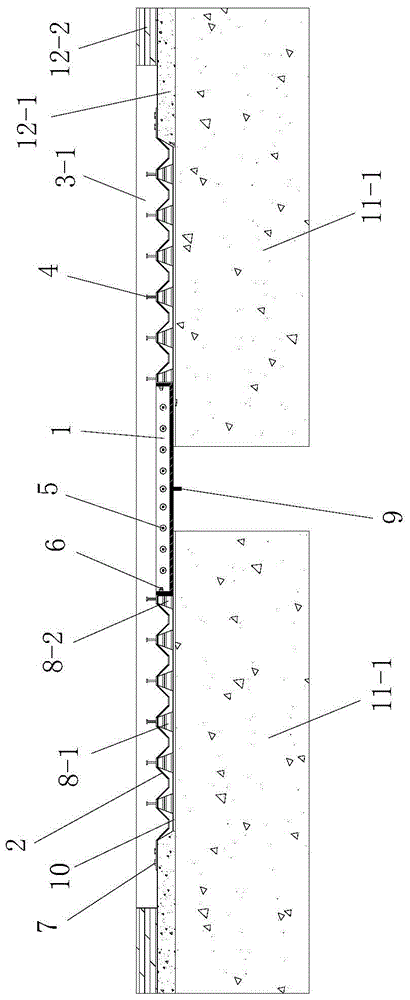

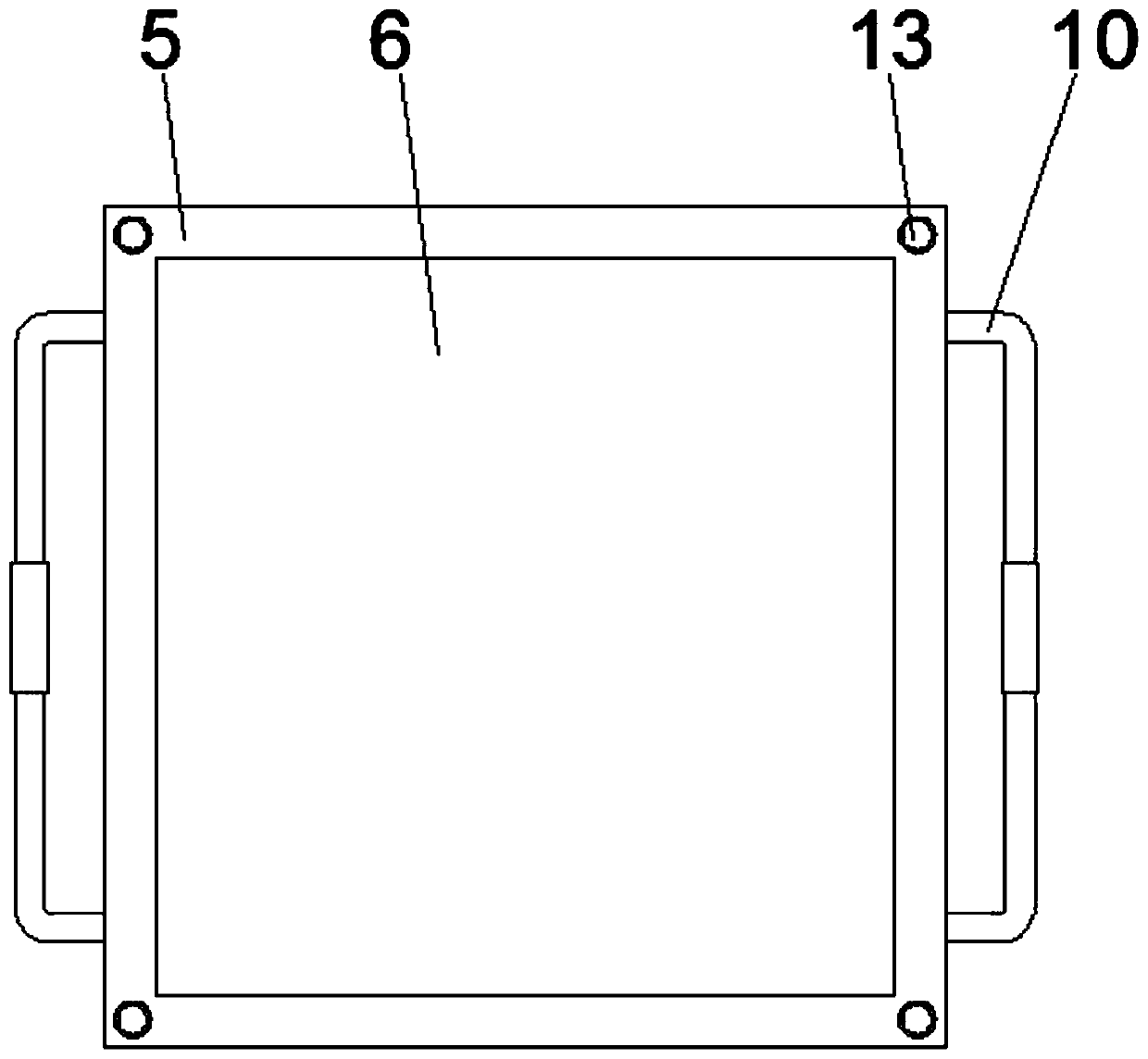

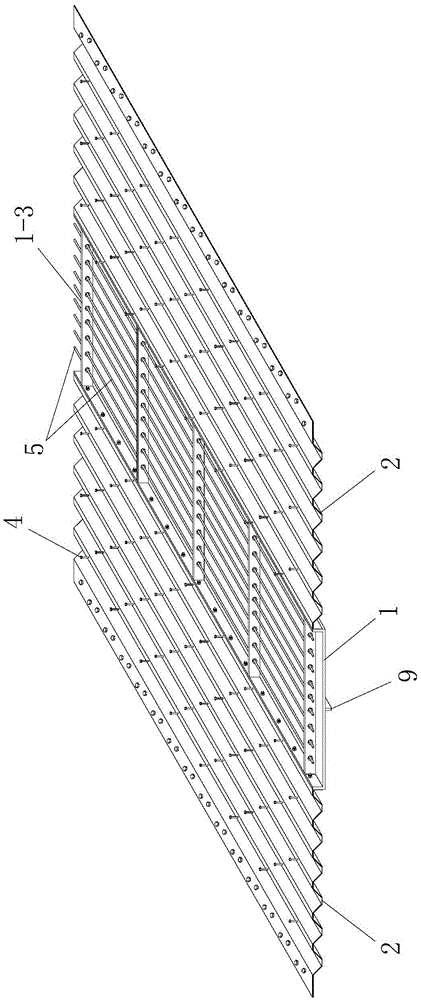

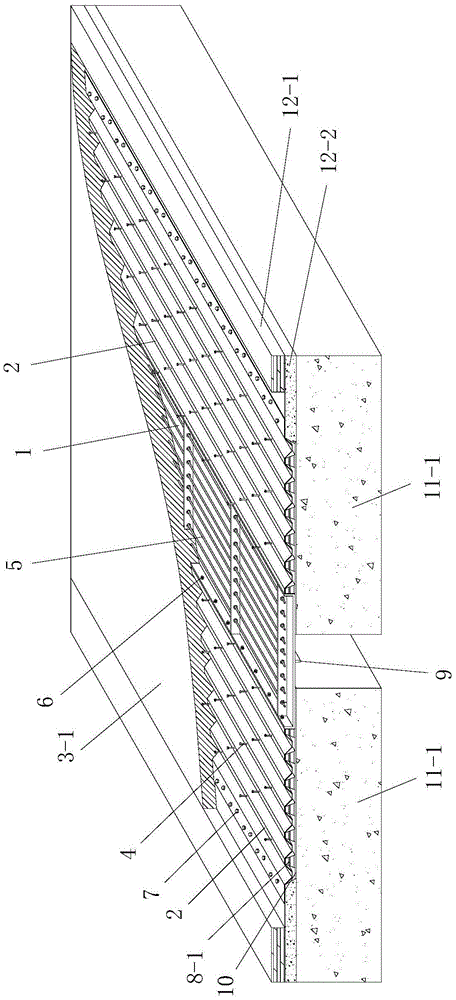

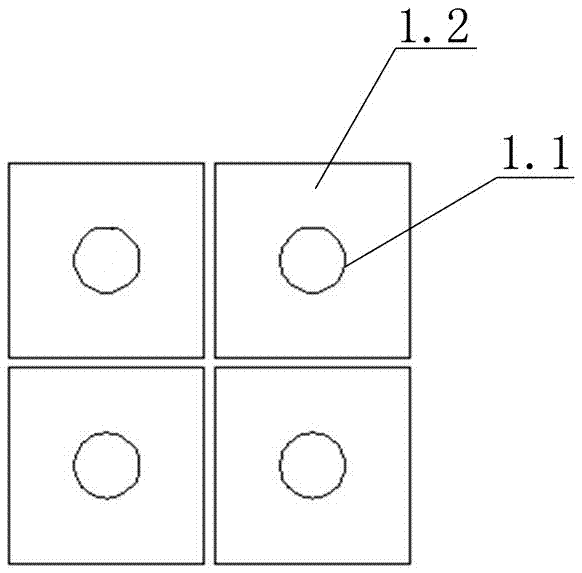

Photovoltaic module device

InactiveCN104660157AEasy to adjustImprove splicing efficiencyPhotovoltaic supportsPhotovoltaic energy generationMechanical engineeringBuilding construction

Owner:杨光

A kind of plastic nail component and its connection method for the connection of building shaped formwork

ActiveCN113585747BIsotropic mechanical properties are not affected in any wayEffect of isotropic mechanical propertiesAuxillary members of forms/shuttering/falseworksArchitectural engineeringStructural engineering

The invention provides a plastic nail assembly and a connection method for connecting building shaped templates, and relates to the technical field of building templates. Including nail sleeves, nail mortises and nail tenons; the bottom of the inner groove set by the nail sleeves is provided with sets of teeth, and the outer wall is provided with multiple rail grooves; ; Nails are provided with shoulders, ridges and elastic bodies, and the inner wall of the shoulders is provided with grooves. The connection method is as follows: assemble the two nail sleeves opposite to each other to form a nail hole, insert them into the connecting hole of the required formwork and abut against the shoulder of the sleeve; put the nail sockets close to the inside of the side rib of the connected formwork, snap into the nail sleeves vertically, and insert the nail sockets into the groove rail In the exposed nail sleeve rail groove closest to the slab rib, the preset nail hole assembly is completed; the vertical formwork is assembled to align the connecting hole with the preset nail hole, and the nail tenon penetrates into the preset nail hole so that the tenon teeth It occludes with the sets of teeth, restricts the nails and tenons from coming out in reverse, and completes the plastic nail connection through forward operation. This method effectively reduces the quality defects that are easy to occur in reverse operations, and avoids safety hazards caused by high-altitude operations.

Owner:天津仝元材料科技有限公司

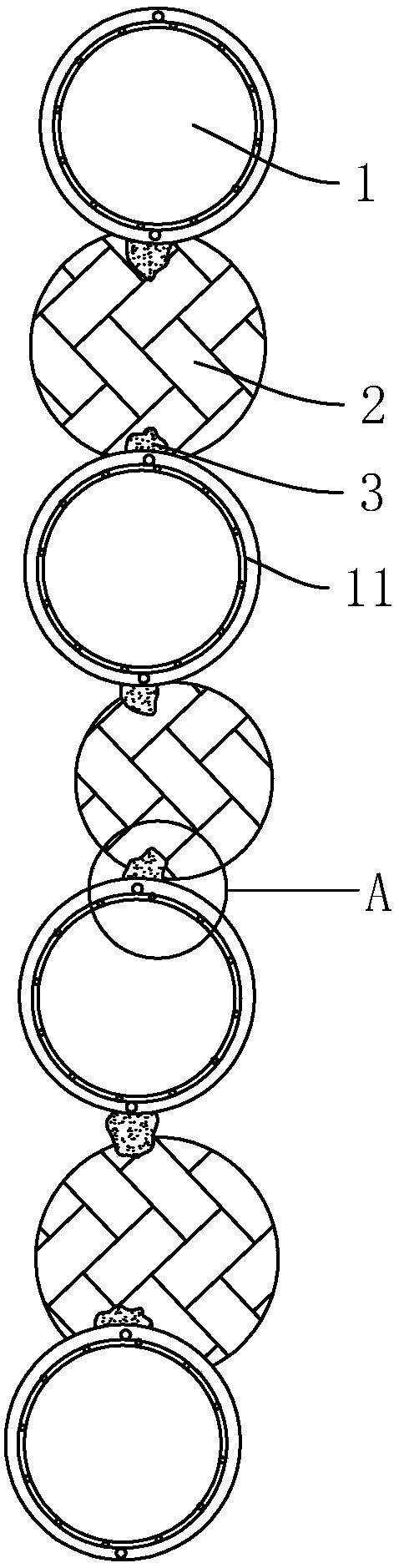

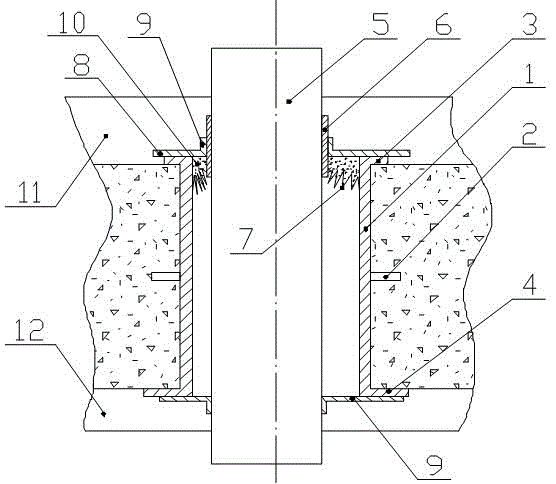

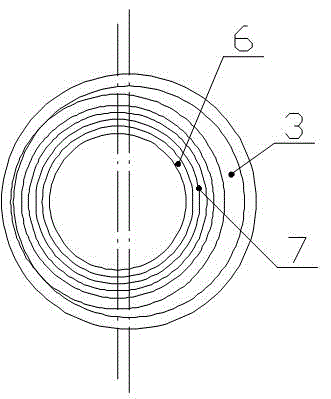

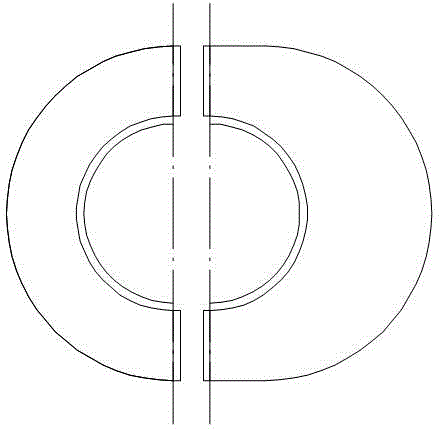

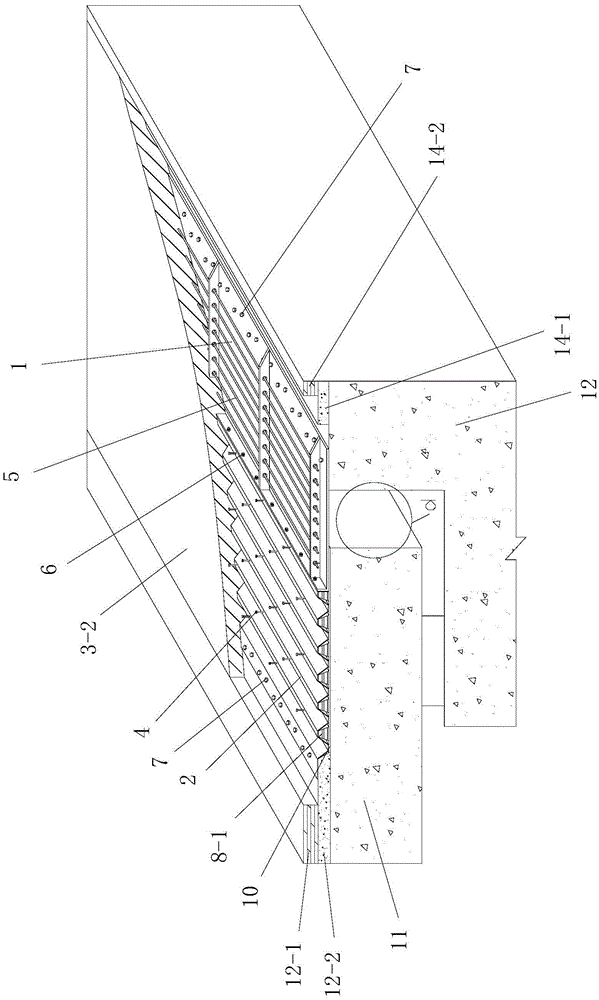

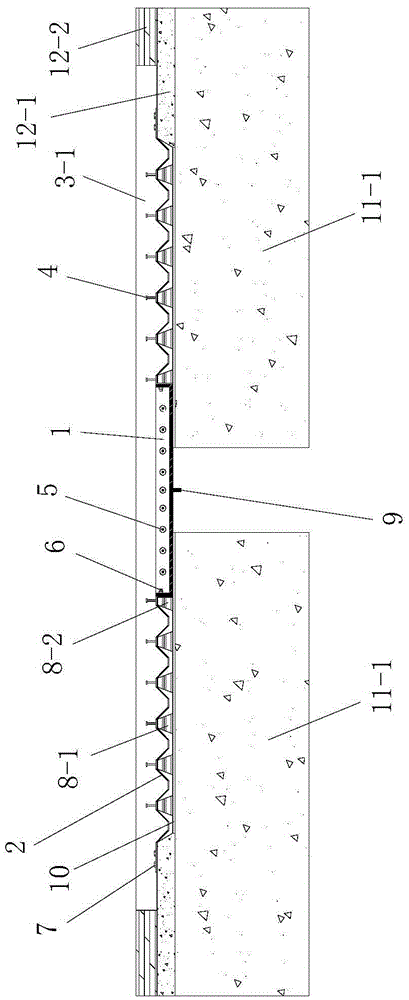

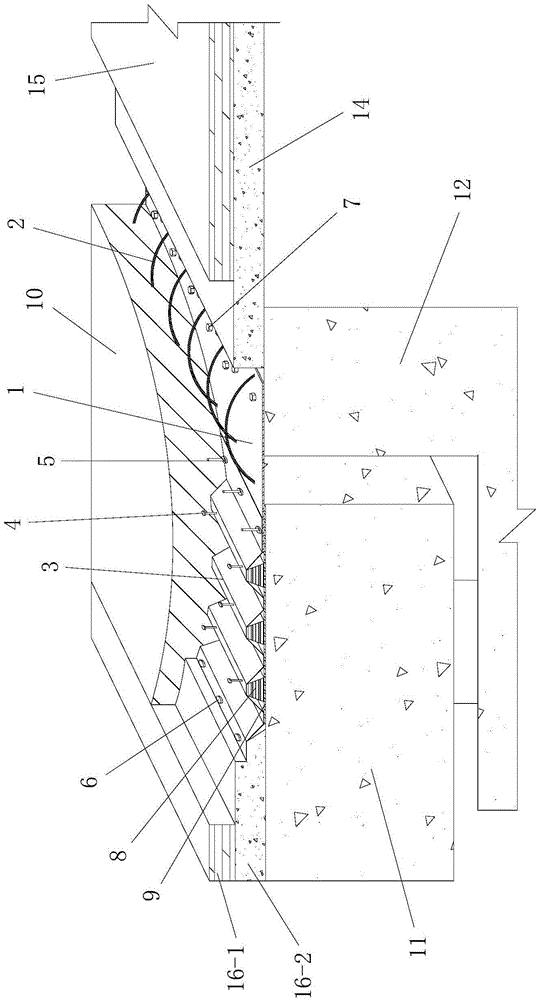

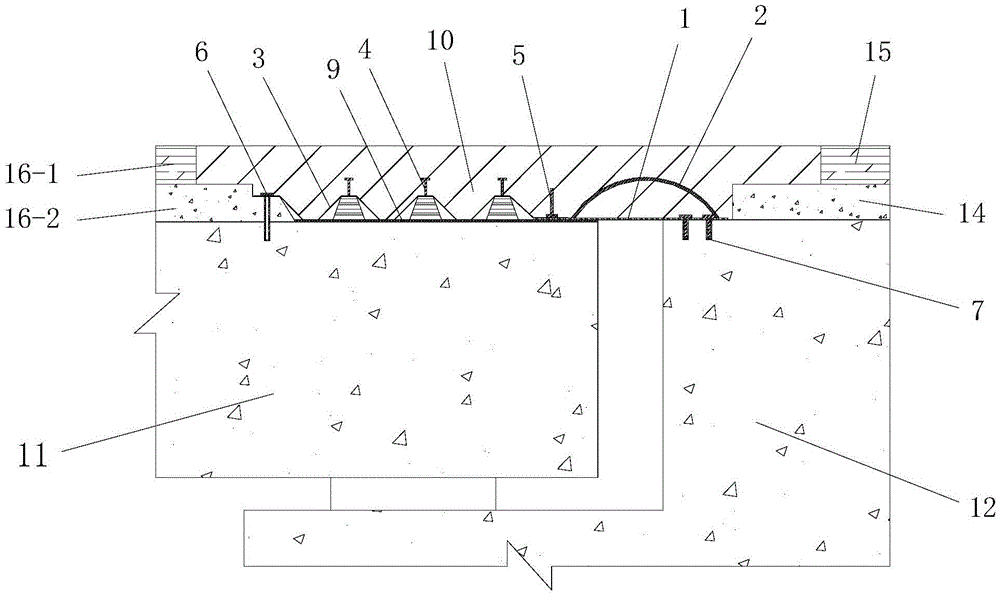

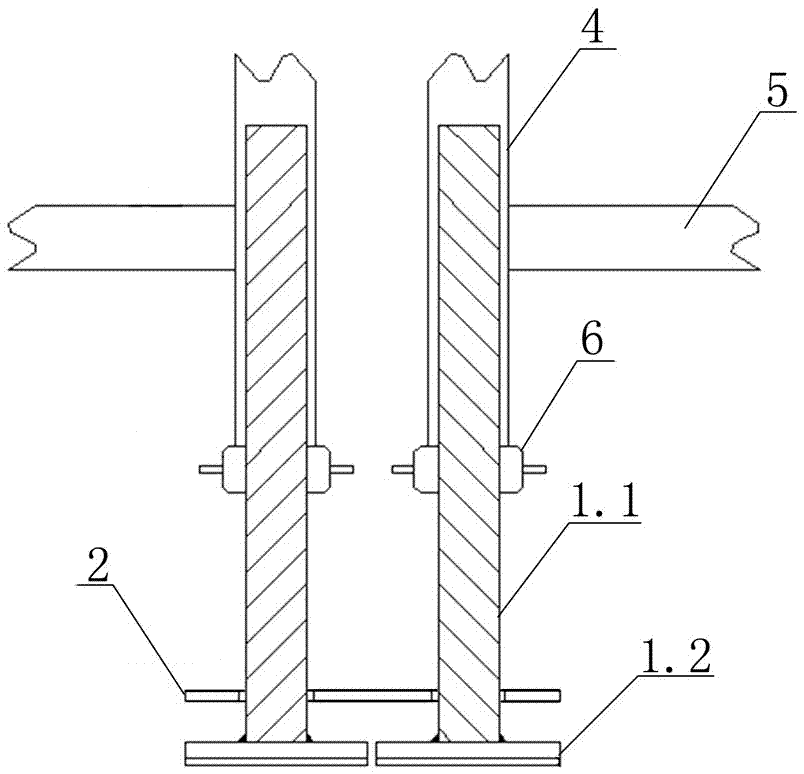

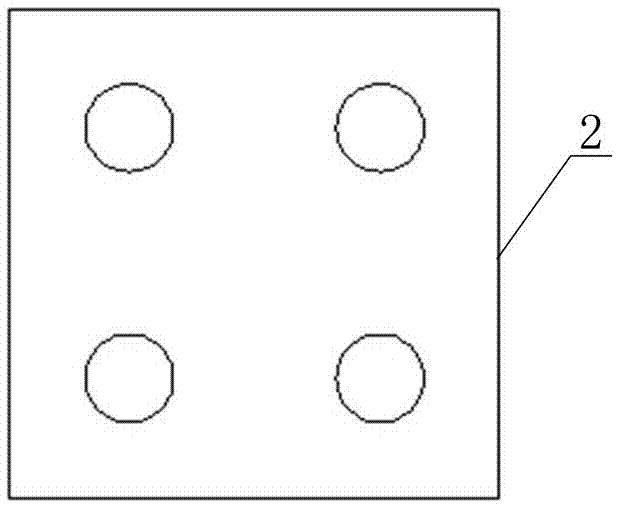

Non-plugging vertical pipe slab penetrating embedment piece and construction method thereof

InactiveCN102733601BQuality improvementAvoid construction errorsForms/shuttering/falseworksBuilding material handlingArchitectural engineeringRelative motion

The invention discloses a non-plugging vertical pipe slab penetrating embedment piece and a construction method thereof. The slab penetrating embedment piece comprises a pipe body which penetrates through a slab; a water stop ring is arranged on the outer circumferential wall of the pipe body; an upper outward flange ring and a lower outward flange ring are arranged on upper and lower ports of the pipe body respectively; a pipe sleeve which is used for being adhered to the vertical pipe is arranged in an inner cavity of the pipe body; and an elastic membrane is arranged between the pipe body and the pipe sleeve, so that the pipe sleeve can do relative motion in the pipe body. According to the slab embedment piece, the inner diameter of the pipe body is greater than the outer diameter of the vertical pipe, so that the vertical pipe has certain movement room, and the construction errors are eliminated; and the slab embedment piece can be tightly combined with the slab, and is waterproof and reliable, convenient to construct and high in using value.

Owner:福州市第三建筑工程公司

A bridge seamless telescopic device and its construction method

InactiveCN104594190BSimple structureWell formedBridge structural detailsBridge erection/assemblyWave shapeAbutment

The invention discloses a bridge seamless telescopic device and a construction method of the device. The bridge seamless telescopic device comprises a main beam span telescopic device and a bridge abutment telescopic device, wherein the main beam span telescopic device comprises a first prefabricated telescopic component and a first telescopic joint filler filling layer; the bridge abutment telescopic device comprises a second prefabricated telescopic component and a second telescopic joint filler filling layer; the first prefabricated telescopic component and the second prefabricated telescopic component are formed by reinforced joint-crossing plates and wave-shaped telescopic plates. A construction method of a telescopic device to be repaired comprises the following steps: cleaning an original bridge telescopic device, constructing a preserved mounting slot, constructing a sliding layer, assembling and mounting prefabricated telescopic components, and constructing telescopic joint filler filling layers. A construction method of a telescopic device to be constructed comprises the following steps: prefabricating and processing prefabricated telescopic components, assembling the prefabricated telescopic components on site, constructing a sliding layer, mounting prefabricated telescopic components, paving a structure and constructing telescopic joint filler filling layers. The bridge seamless telescopic device is reasonable in design, convenient to construct and high in using effect, and can be used for solving various problems of the existing telescopic device.

Owner:XIAN HIGHWAY INST

Seamless telescopic device between main girder and abutment with built-in corrugated steel plate and its construction method

InactiveCN104594191BWell formedSimple structureBridge structural detailsBridge erection/assemblyArchitectural engineeringBridge deck

The invention discloses a corrugated steel plate built-in seamless expansion device between a girder and a bridge abutment and a construction method of the seamless expansion device. The expansion device comprises prefabricated steel plate elements distributed on a bridge abutment expansion joint and expansion joint filler packing layer filled above the prefabricated steel plate elements; the prefabricated steel plate elements comprise straight steel plates, corrugated steel plates and a plurality of arched reinforcing steel bars; a plurality of shear pins are fixed on the corrugated steel plates; a sliding layer is paved on the girder exposed section; the construction method of the to-be-repaired expansion device comprises the following steps: cleaning the original bridge expansion device, constructing preserved mounting grooves, constructing the girder sliding layer, assembling the prefabricated steel plate elements in the field, and mounting and constructing the expansion joint filler packing layer; the construction method of the to-be-constructed expansion device comprises the following steps: prefabricating and processing the prefabricated steel plate elements, assembling the prefabricated steel plate elements in the field, constructing the girder sliding layer, mounting the prefabricated steel plate elements, and constructing the bridge deck pavement structure and the expansion joint filler packing layer. The corrugated steel plate built-in seamless expansion device disclosed by the invention is reasonable in design, convenient to construct, and good in use effect, and can solve a plurality of problems in the existing expansion device.

Owner:XIAN HIGHWAY INST

Reconstruction method of long-span tied arch bridge based on bridge hydraulic jacking system

ActiveCN110424245BReasonable structural designEasy to installBridge erection/assemblyBridge strengtheningArchitectural engineeringStructural engineering

The invention discloses a reconstruction method for a large-span tied arch bridge based on a bridge hydraulic jacking system. The reconstructed bridge includes a main bridge and two approach bridges; when reconstructing the reconstructed bridge, the steps include: step 1: lifting the bridge And the construction of the new approach bridge: use the bridge hydraulic jacking system to carry out jacking construction on the superstructure of the bridge to be jacked up and the two main beams 1 of the approach bridge to be jacked up; step 2, follow-up construction. The method of the invention is reasonable in design, simple in construction and good in use effect. It is simple and fast to complete the construction process of jacking up the large-span arch bridge, and the jacking process is safe and reliable; in addition, when the original bridge superstructure is jacked up, two new approach bridges are built, which can effectively reduce the backfill workload and save construction. duration.

Owner:NO 1 ENG LIMITED OF CR20G

A combined ceiling suspension device and installation method under a tall curved steel structure

ActiveCN107605090BPrecise positioningElimination of problems that cannot be precisely locatedCeilingsMulti directionalElectrical and Electronics engineering

Owner:WUHAN CONSTR ENG

A construction method for jacking up a long-span concrete-filled steel tube tied arch bridge

ActiveCN110424244BReasonable structural designEasy to installBridge erection/assemblyArch-type bridgeArchitectural engineeringPier

The invention discloses a construction method for jacking up a long-span concrete-filled steel pipe tied arch bridge. The bridge to be jacked up includes a main bridge and two approach bridges. When jacking up the bridge to be jacked up, steps are included: 1. Preparation before jacking up Work: Separate the connection ends of all longitudinal girders in the two approach bridges from the assembled girder body, and separate the assembled girder body from the two supporting piers, and simultaneously separate all the longitudinal girders in each approach bridge from the supported The lower support structure of the approach bridge is separated; 2. Jacking: When jacking up the bridge to be lifted, the main bridge and the two approach bridges are jacked up separately; 3. The lower structure of the main bridge is raised. The method of the present invention is reasonable in design, easy in construction and good in use effect. The main bridge and the two approach bridges are respectively jacked up, and the structures and layout positions of the adopted approach bridge jacking system and the main bridge jacking system are specifically limited. The jacking construction process of the long-span arch bridge is completed simply and quickly, and the jacking process is safe and reliable.

Owner:NO 1 ENG LIMITED OF CR20G +1

A hidden telescopic device at the bridge abutment and its construction method

InactiveCN104762873BWell formedSimple structureIn situ pavingsBridge structural detailsBridge deckAbutment

The invention discloses an abutment hidden expansion device and a construction method thereof. The expansion device comprises a prefabricated expansion component arranged on an abutment expansion joint, and an expansion joint filler filling layer filled in the upper side of the prefabricated expansion component, wherein a bridge deck pavement structure is paved on a main beam; a slide layer is paved on an exposed section of the main beam; a road surface pavement layer is arranged at the outer side of the upper part of an abutment; the prefabricated expansion component comprises a reinforced joint plate and a waveform expansion plate; a construction method of an expansion device to be repaired comprises the steps of cleaning of an original bridge expansion device, construction of a reversed mounting groove, construction of the slide layer, field assembly and installation of the prefabricated expansion component and construction of the expansion joint filler filling layer; and a construction method of an expansion device to be constructed comprises the steps of prefabrication of the prefabricated expansion component, field assembly of the prefabricated expansion component, construction of the slide layer, installation of the prefabricated expansion component and construction of the bridge deck pavement structure and the expansion joint filler filling layer. The abutment hidden expansion device and the construction method thereof have the advantages of reasonable design, convenience for construction and good use effect, and can solve multiple problems in traditional expansion devices.

Owner:XIAN HIGHWAY INST

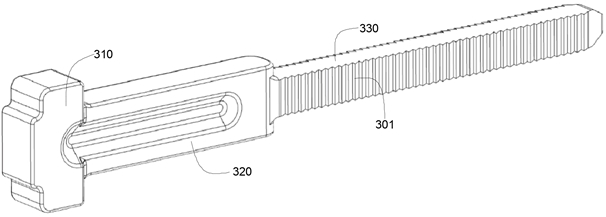

Pneumatic bolt quick disassembly equipment

ActiveCN111503082BQuick disassemblyGuarantee the construction qualityServomotor componentsRock boltHigh pressure gas

The invention discloses a quick disassembly and assembly device for pneumatic anchor rods. The invention realizes quick disassembly and assembly of anchor rods through an anchor rod lifting assembly and a pneumatic assembly fixed on a base. The pneumatic assembly outputs high-pressure gas to the anchor rod elevating assembly for its Provide the power for lifting activities. When disassembling and assembling the anchor, you only need to assemble the anchor and the anchor lifting assembly, and then use the air pressure generated by the high-pressure gas to push the anchor to move, so as to realize the disassembly and assembly of the anchor. The present invention does not require manual labor when disassembling and assembling the anchor rod, thereby saving a large amount of labor costs, and because there is no manual intervention during disassembly and assembly, it can effectively avoid construction errors caused by manual operation, and can effectively ensure the safety of the anchor rod. Construction quality: the invention is easy to assemble and cooperate with the anchor rod, and the assembly steps can be completed in a short time during repeated construction, thereby shortening the construction period and improving construction efficiency.

Owner:CHINA 19TH METALLURGICAL CORP

Construction method of construction operation platform in deep peat soil area

ActiveCN109083122BImprove bearing capacityGuaranteed uptimeRoadwaysSoil preservationPeatMechanical equipment

The invention provides a construction method of an operation platform for construction in a deep and thick peat soil area. The construction method comprises the following steps that D, within the range of a machine arm of an excavation machine, a roadbed trough is excavated; E, geotechnical cloth is laid on the bottom of the roadbed trough; F, sea sand is filled back into the roadbed trough, and aprimary platform is formed; G, the excavation machine is moved to the primary platform obtained in the former step; and H, the steps from D to G are repeated until all primary platforms in the construction area are completed, wherein in the step H, every time after the primary platform of a certain distance length is completed, the sea sand is filled back above the primary platforms and compacted, and the operation platform for construction is formed. According to the construction method, permeable performance and reinforced performance of sea sand resources and the geotechnical cloth are fully utilized, the bearing ability of the base is enhanced, it is ensured that equipment comes in and out of a site and operates normally, the construction error of the mechanical equipment due to uneven settlement is avoided, and the reliable guarantee is provided for construction of follow-up foundation treatment.

Owner:CHINA MCC20 GRP CORP

Connecting piece for enhancing bearing capacity of tool-type scaffolding and installation method thereof

ActiveCN105625706BImprove bearing capacityImprove integrityScaffold connectionsCarrying capacityEngineering

The invention discloses a connecting piece for enhancing the bearing capacity of a tool type scaffold and an installing method of the connecting piece. The connecting piece comprises lower adjusting lead screw bases, a base fixing plate and an upper fixing connecting piece body. Lead screws of the four lower adjusting lead screw bases are sleeved with the base fixing plate and sleeved with the lower portions of four adjacent stand columns of the tool type scaffold respectively. The upper fixing connecting piece body comprises a bearing top plate, outer sleeves, inner sleeves, a limiting plate and upper connecting bolts. The upper portions of the four adjacent stand columns of the tool type scaffold are inserted in the four outer sleeves of the upper fixing connecting piece body respectively to abut against the limiting plate. When some frame bodies with heights needing to be adjusted and high bearing requirements are erected, by means of the connecting piece, the bearing capacity of the tool type scaffold can be greatly improved, the rigidity and stability required by the tool type scaffold can be achieved, and the connecting piece is easy, convenient and flexible to use and operate and suitable for erecting platforms with large loads and high precision requirements.

Owner:BEIJING NAT AQUATICS CENT CO LTD +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com