Galvanized plate integrated dividing joint and construction method

A separate and integrated technology, applied to floors, buildings, building structures, etc., can solve problems such as long construction period, difficult construction quality assurance, and poor use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

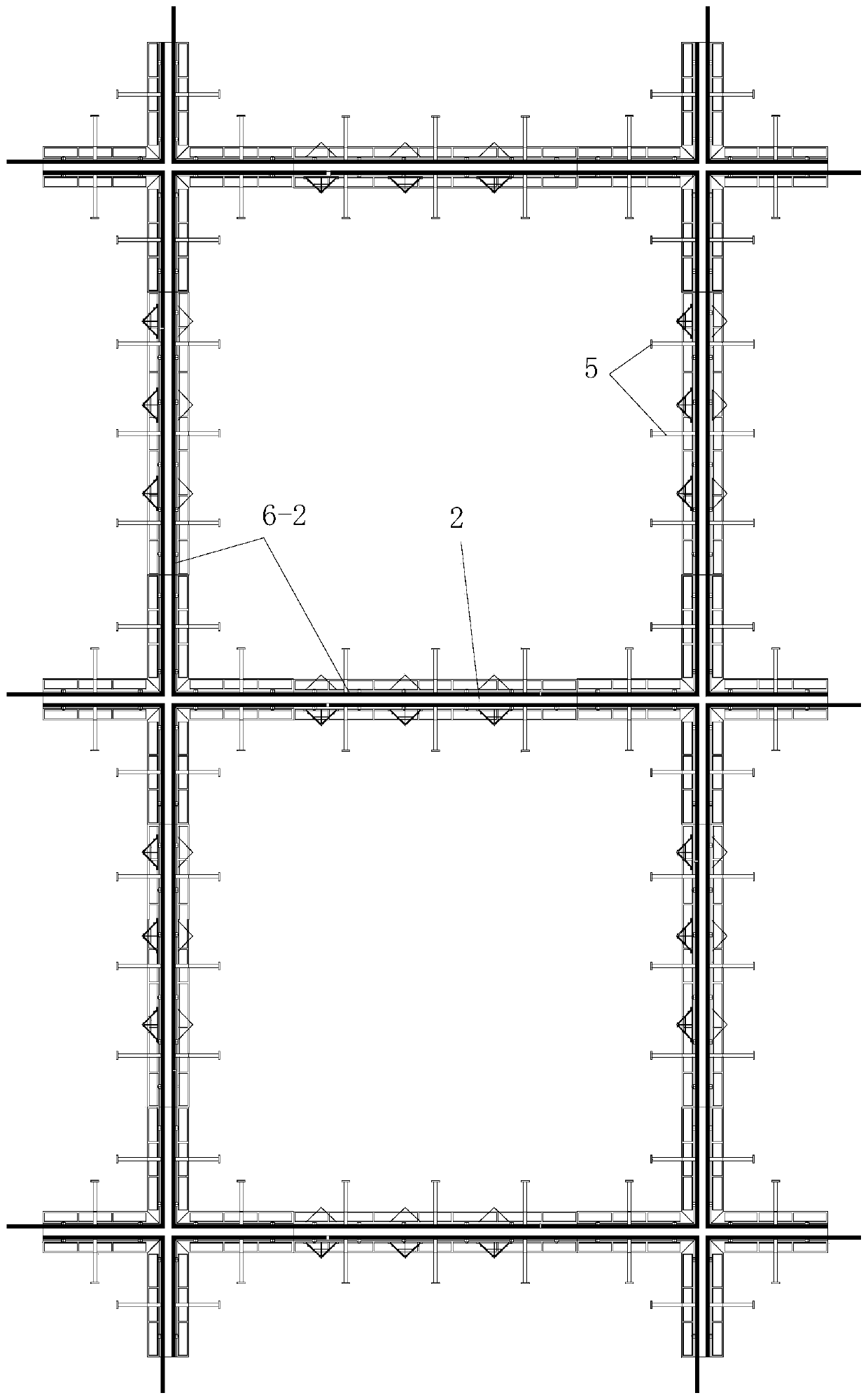

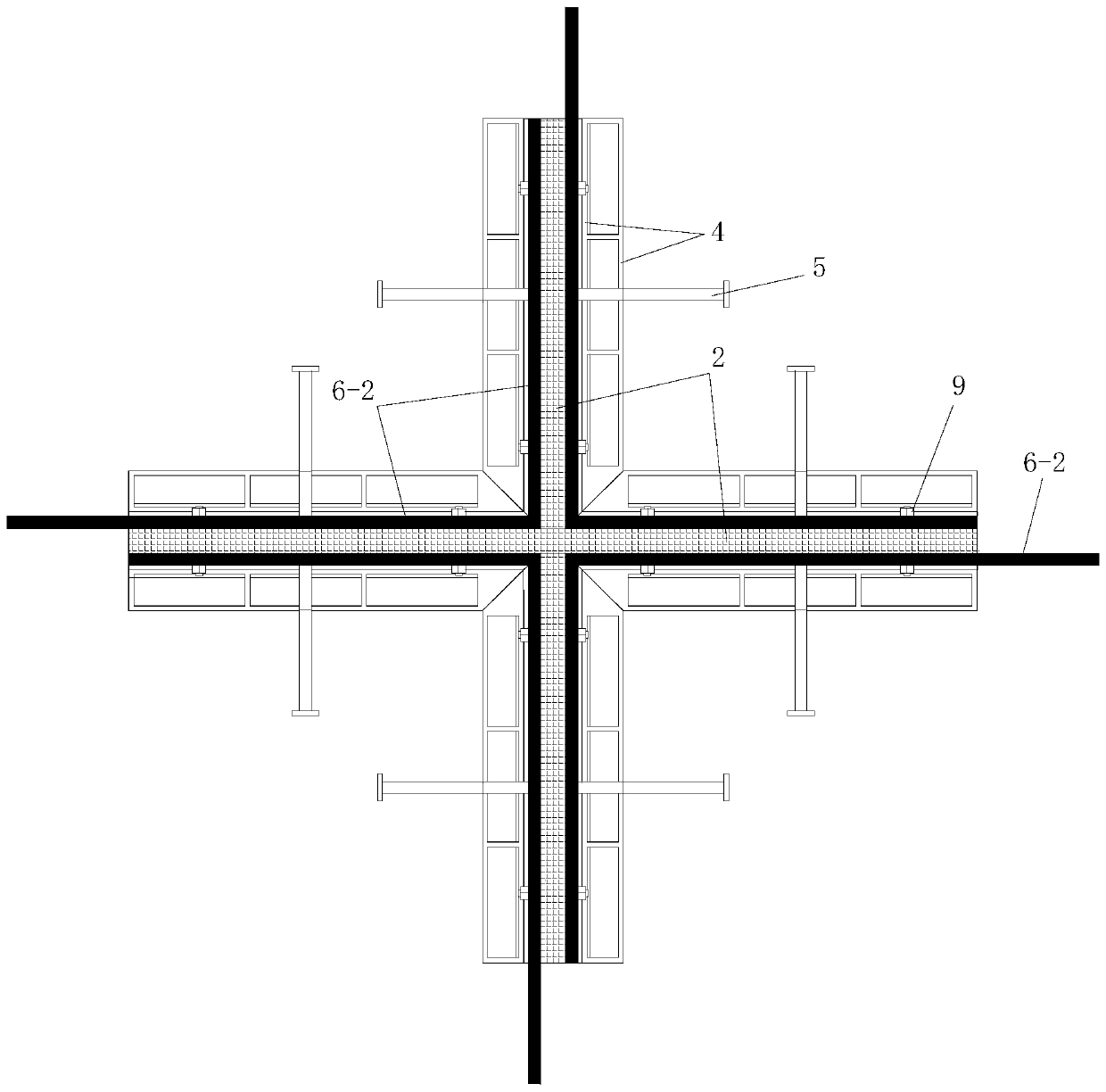

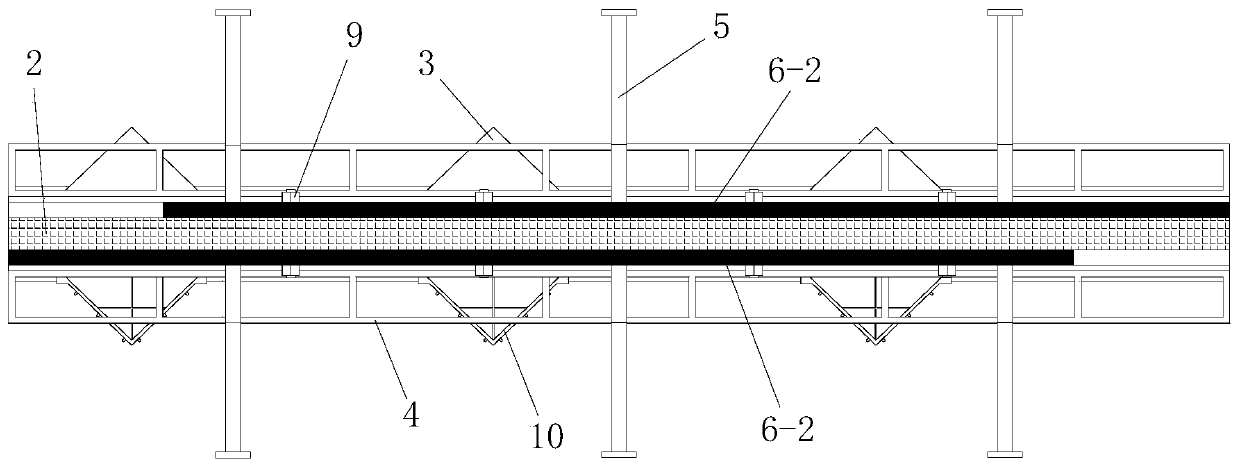

[0086] like figure 1 , figure 2 , image 3 , Figure 4 As shown, the galvanized sheet integrated binning seam of the present invention includes a field assembled binning seam assembled from a plurality of straight binning seams and a plurality of cross-shaped binning seams, and a plurality of straight binning seams The compartment seams and the multiple cross-shaped compartment joints are arranged on the same horizontal plane; the structures of the multiple cross-shaped compartment joints are the same, and each of the cross-shaped compartment joints is arranged horizontally; The structures of the straight sub-storage seams are all the same and they are arranged in multiple rows and columns, and each of the straight sub-storage seams is laid horizontally;

[0087] Each row of said straight bin slits includes a plurality of said straight bin slits arranged on the same row from left to right, and all the straight bin slits in each row of said straight bin slits are in the for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com