A method for installing a contact rail channel of a magnetic levitation track beam and a channel positioning mold thereof

A technology for positioning molds and installation methods, which is applied in the direction of track, track laying, track maintenance, etc., can solve problems such as large limitations and infeasibility, and achieve the effect of eliminating inclined construction errors, eliminating hidden safety hazards, and ensuring parallelism requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

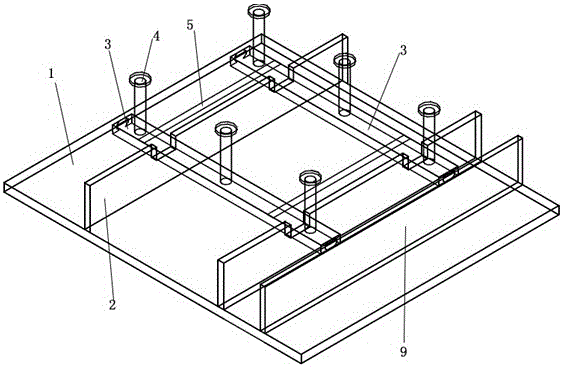

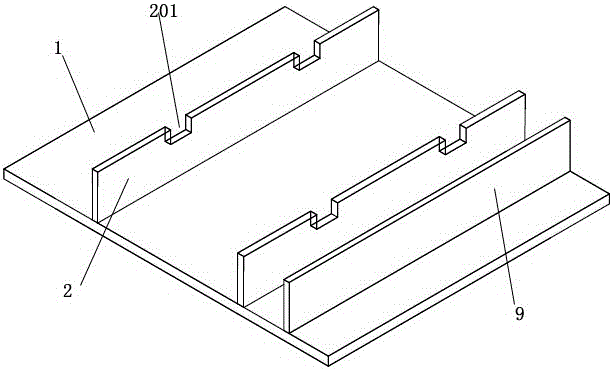

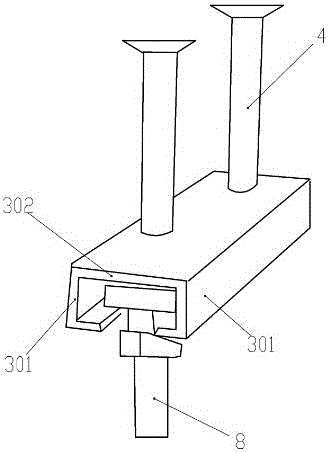

[0036] In this embodiment, the contact rail channel of the magnetic levitation track beam is installed on the track beam of the straight section, such as Figure 1 to Figure 4 As shown, the track beam contact rail channel positioning mold used in this construction method includes a base plate 1 with a flat structure, and two limiting plates 2 arranged in parallel to each other are arranged on the base plate 1. The upper end of the plate 2 is provided with two positioning grooves 201 matching the width of the channel 3, and the distance between the two positioning grooves 201 on the same limiting plate 2 is the same as the preset position of the two channels 3. The distance is adapted, and a retainer 5 for fixing to the ends of the two channels 3 is also included, so that the channel group composed of the two channels 3 can still be kept parallel to each other after being removed from the limiting plate 2 .

[0037] In this embodiment, the two limiting plates 2 are vertically a...

Embodiment 2

[0054] In this embodiment, the contact rail channel of the magnetic levitation track beam is installed on the track beam of the curved section, such as Figure 1 to Figure 5 As shown, the track beam contact rail channel positioning mold used in this construction method includes a base plate 1 with a flat structure, and two limiting plates 2 arranged in parallel to each other are arranged on the base plate 1. The upper end of the plate 2 is provided with two positioning grooves 201 matching the width of the channel 3, and the distance between the two positioning grooves 201 on the same limiting plate 2 is the same as the preset position of the two channels 3. The distance is adapted, and a retainer 5 for fixing to the ends of the two channels 3 is also included, so that the channel group composed of the two channels 3 can still be kept parallel to each other after being removed from the limiting plate 2 .

[0055] In this embodiment, the two limiting plates 2 are vertically arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com