A Diesel Engine Cylinder Block Handling and Packing Equipment

A diesel engine and cylinder block technology, applied in the field of diesel engine cylinder block handling and packing equipment, to achieve the effect of ensuring structural strength and structural stability, ensuring accuracy and reliability, and wide operating area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

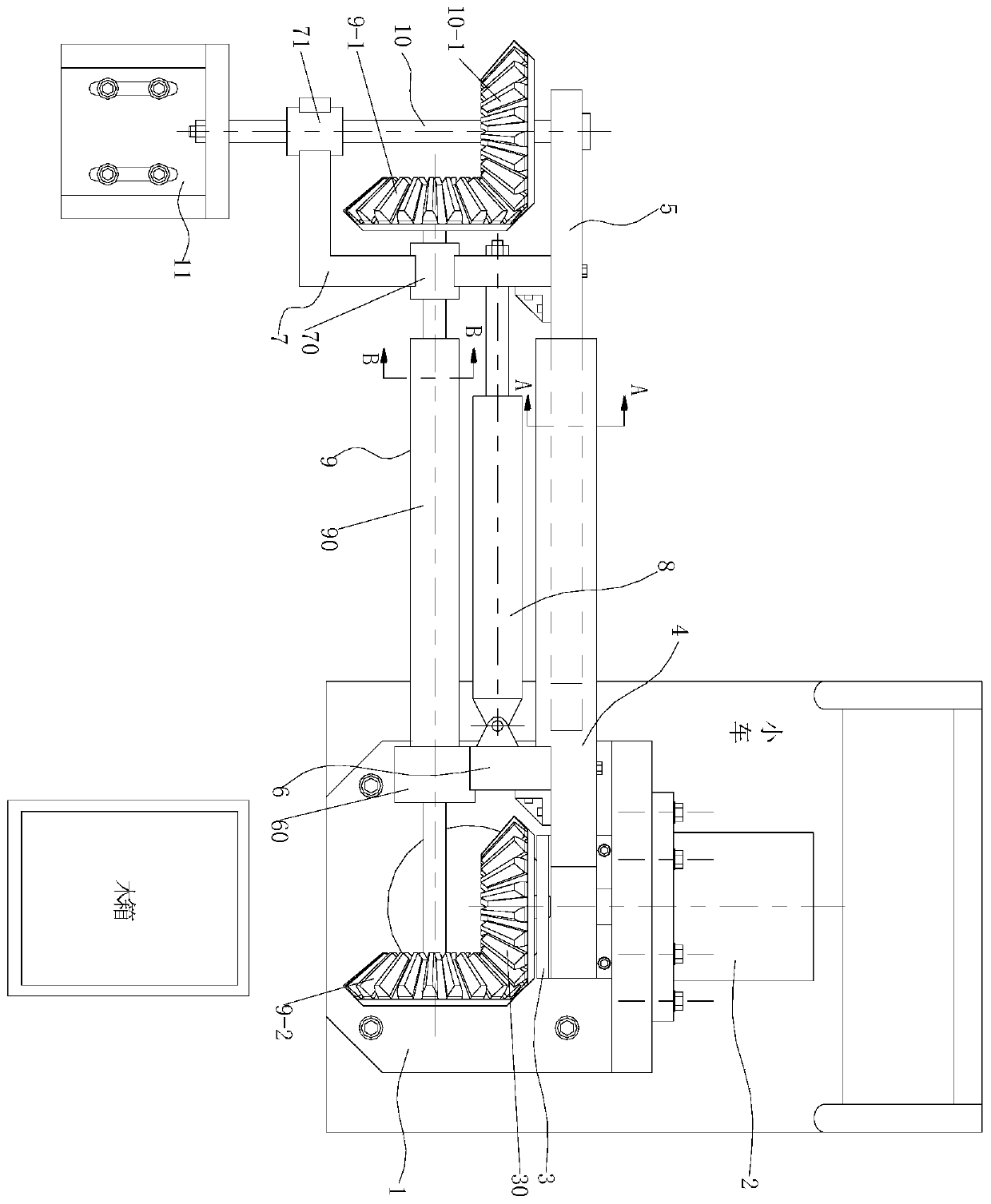

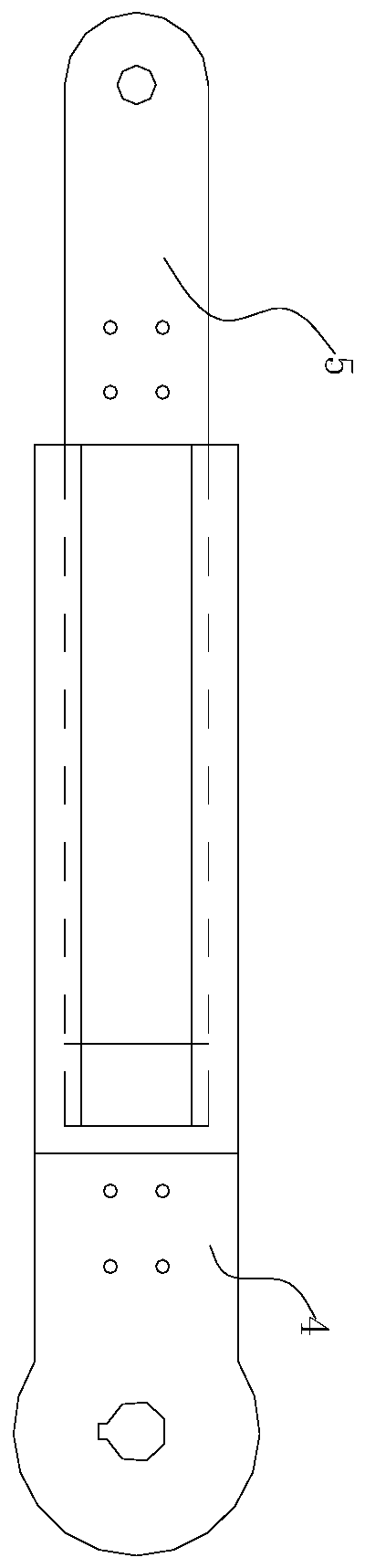

[0038] Refer to attached figure 1As shown, the trolley in this embodiment moves to the side of the diesel engine cylinder to be transported or boxed, and the electromagnet 11-1 and the diesel engine cylinder are in the same vertical plane position, and then the servo motor 2 is started, and the servo motor 2 The output shaft rotates forward or reversely to drive the rotary plate 4 to rotate forward or reverse synchronously around the axis of the output shaft of the servo motor 2, and then the rotary plate 4 carries the telescopic plate 5, the first axle frame 6, the second axle frame 7, and the telescopic rod 8. The telescopic shaft assembly 9, the rotating shaft 10 and the connecting frame 11 connected to the end of the rotating shaft 10 move together to a horizontal state. During this process, the bevel gear 2 9-2 is constrained to rotate by the fixed bevel gear 30, and then the bevel gear 2 9-2 rotates with the spline shaft 90, because the spline shaft 91 is axially sliding...

Embodiment 2

[0040] On the basis of Embodiment 1, the servo motor 2 drives the rotary plate 4 to rotate within an angle range of 180 degrees, so as to realize the adsorption and transportation of the diesel engine cylinders on both sides of the trolley; in addition, the telescopic rod 8 can pass through the axle frame 2 7 and the telescopic plate 5 Change the position of the rotating shaft 10 in the radial direction, so that the electromagnet 11-1 has a wide operating area and high flexibility. When the rotating plate 4 is in a horizontal state, it can absorb the far diesel engine cylinder; when the electromagnet 11-1 absorbs After the diesel engine cylinder is installed, the placement height can also be changed through the expansion and contraction of the telescopic rod 8, which has a wide range of applications; it can also be used to carry and place other large ferromagnetic workpieces, not limited to the diesel engine cylinder.

Embodiment 3

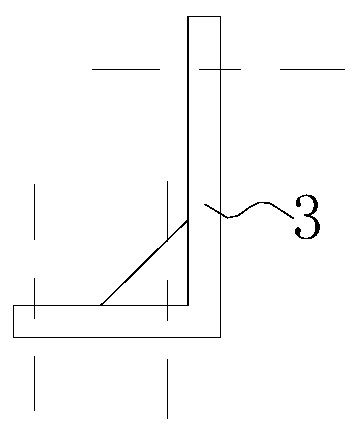

[0042] On the basis of Embodiment 1, the center of the small mounting seat 3 is fixed with a fixed bevel gear 30, and the central axis of the fixed bevel gear 30 is collinear with the axis of the output shaft of the servo motor 2, ensuring that the fixed bevel gear 30 In order to fix and constrain the gears and realize the planar movement of the connecting frame 11; the large mounting seat 1 is an "L"-shaped structure, and the small mounting seat 3 is an "L"-shaped structure, which ensures that the electromagnet 11-1 absorbs the workpiece structural strength and structural stability; the first shaft frame 6 is a "one"-shaped structure, and the second shaft frame 7 is an "L"-shaped structure, which realizes the parallel installation of the telescopic rod 8 and the telescopic shaft assembly 9, and ensures The support and rotation of the spline cylinder shaft 90 and the spline shaft 91 are improved, and the stability of the meshing of the first bevel gear 9-1 with the third bevel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com