Roof steel structure and air duct synchronous sliding construction method

A construction method and synchronous sliding technology, which is applied in the direction of building structure, construction, and building material processing, etc., can solve problems such as difficult construction, long construction period, and complicated construction process, so as to achieve convenient and safe installation and operation, and reduce operation Error, the effect of improving installation efficiency and installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

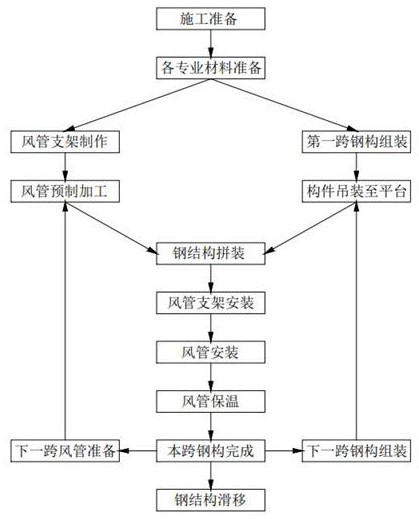

[0043] The embodiment of the present invention discloses a synchronous sliding construction method of a roof steel structure and an air duct, which includes the following construction steps:

[0044] S1. Model the entire system through BIM software, determine the structure and location of the air duct, including the size parameters and position information of the air duct, and the structure and position information of the steel structure support;

[0045] S2. Prefabricate construction materials and devices according to the data of the BIM model, including the prefabrication processing of the air duct support and the prefabrication processing of the steel structure support;

[0046] S3. Install the sliding track and the sliding assembly platform;

[0047] S4, assembling the steel structure support, including ground assembly and hoisting of the steel structure support;

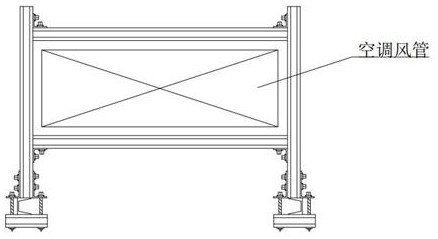

[0048] S5. Install the air duct support, and perform hoisting of the air duct according to the position info...

Embodiment 2

[0058] Based on embodiment 1, the following technical solutions can be adopted:

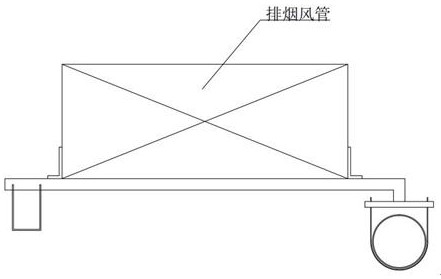

[0059] The air ducts are hoisted in groups and installed in order to connect the air duct groups. The joints of the air duct groups are connected by flange bolts and the edges of the flanges are coated with sealant. The flanges are padded with flame retardant materials. .

[0060] The flame retardant material is a 4mm thick flame retardant closed cell sponge rubber strip.

[0061] The sliding speed of the overall sliding is 5-8m / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com