Pile-spanning waterproof heavy curtain combined pile side sleeve valve pipe grouting and water stopping construction method

A sleeve valve pipe grouting and water-stop curtain technology, which is applied in infrastructure engineering, construction and other directions, can solve the problems of water-stop curtain and slope protection pile leakage, weak contact surface, vertical deviation and other problems, so as to avoid construction errors, The effect of simple positioning and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

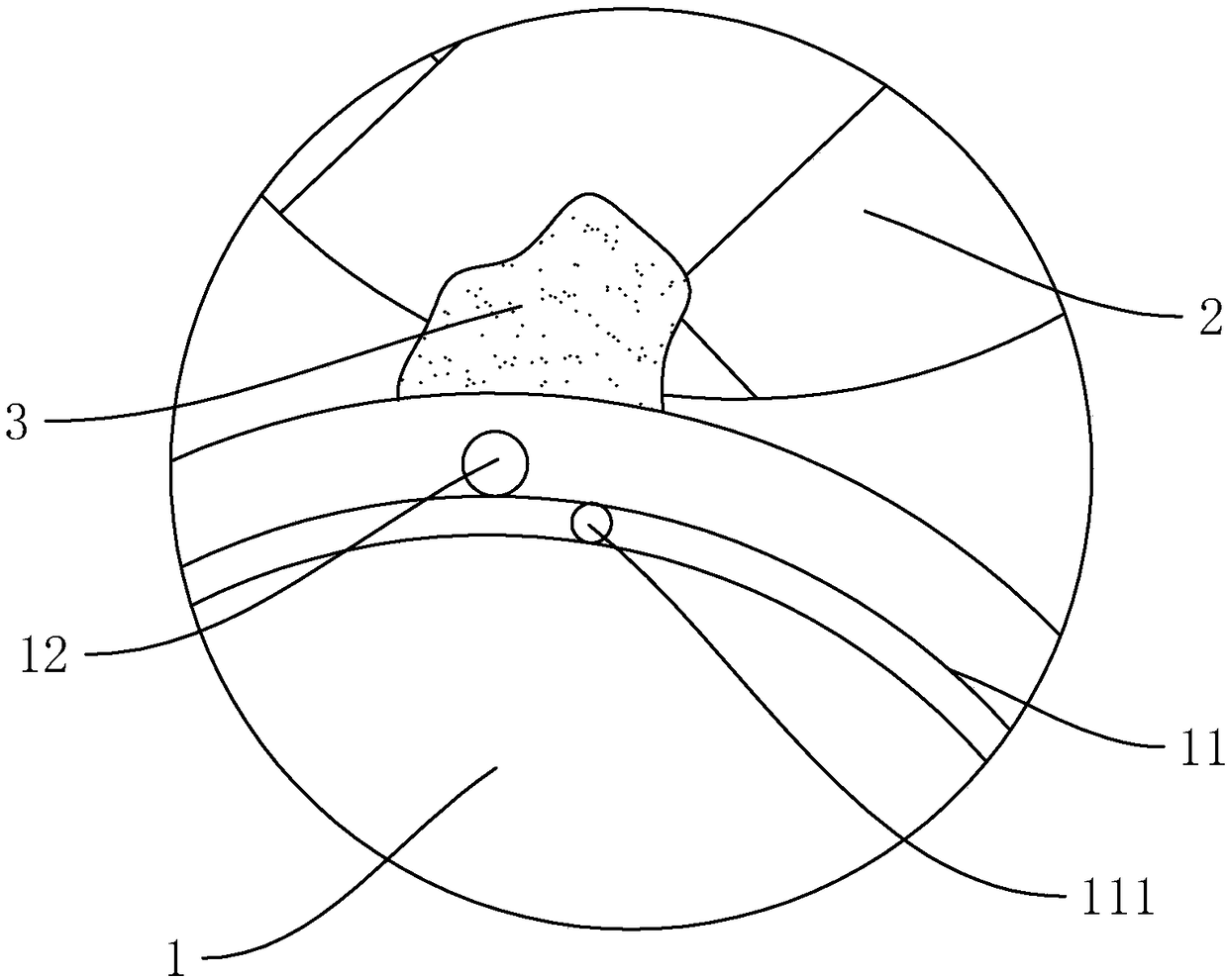

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings, wherein the same components are denoted by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower", "bottom" and "top" used in the following description refer to the Directions, the words "inner" and "outer" refer to directions toward or away from, respectively, the geometric center of a particular component.

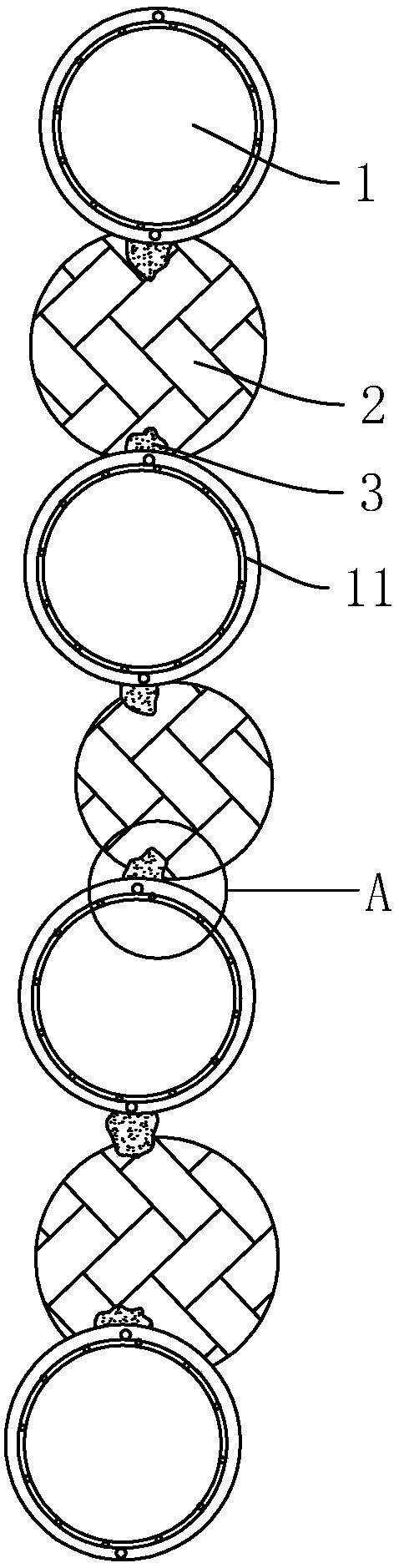

[0029] A water-stop curtain construction method in which a water-stop curtain pile 2 is combined with a slope-protection pile 1 is constructed between the slope-protection piles 1. There are situations where the contact surface between the slope-protection pile 1 and the water-stop curtain pile 2 is weak or the verticality is deviated, which may easily lead to a water-stop curtain. Leakage is formed between the pile 2 and the slope protection pile 1. In order to solve the above problems, the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com