Non-plugging vertical pipe slab penetrating embedment piece and construction method thereof

A construction method and technology for floor slabs, which are applied in the fields of formwork/template/work frame, on-site preparation of building components, and construction, can solve problems such as affecting the quality of the floor slab structure, low user satisfaction, time-consuming and material-consuming, and achieving construction The effect of high efficiency, low cost and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings, but the present invention is not limited thereto.

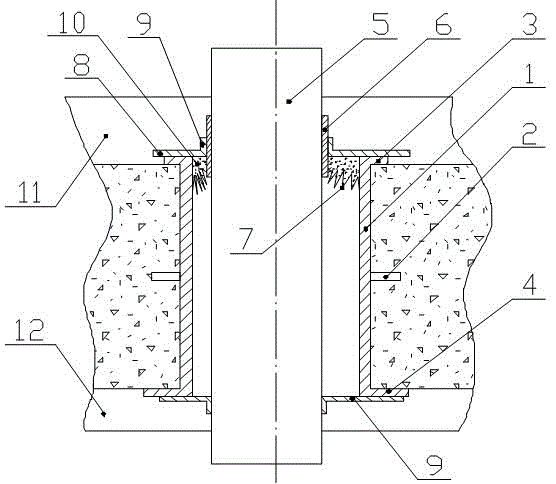

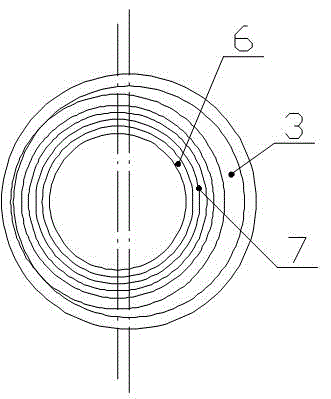

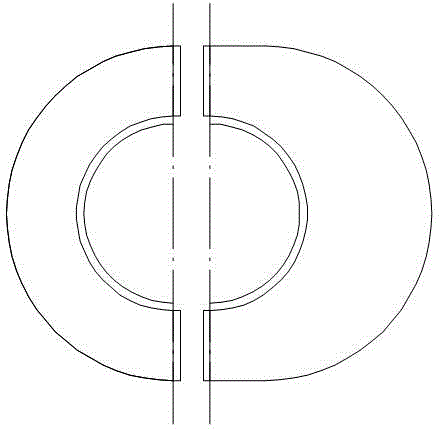

[0025] See attached figure 1 ~3. The non-blocking riser piercing floor embedment of the present invention includes a pipe body 1 for passing through the floor. The outer peripheral wall of the pipe body 1 is provided with a water stop ring 2. The pipe body 1 The upper and lower ports are respectively provided with an upper outer flange ring 3 and a lower outer flange ring 4, and the inner cavity of the pipe body 1 is provided with a pipe sleeve 6 for bonding with the standpipe 5, and the pipe body 1 and the pipe body An elastic diaphragm 7 is arranged between the sleeves 6 to facilitate relative movement of the sleeve 6 in the tube body 1 . It should be noted that the material of the elastic diaphragm 7 is sof...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com