Bridge seamless telescopic device and construction method of device

A telescopic device, seamless technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of uncomfortable bridge passers-by, vulnerable road traffic of bridge telescopic devices, lack of sense of security, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

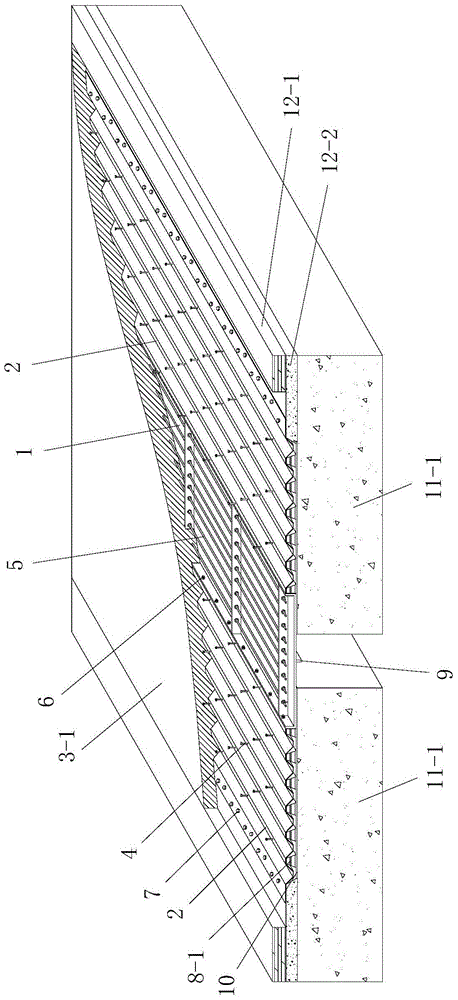

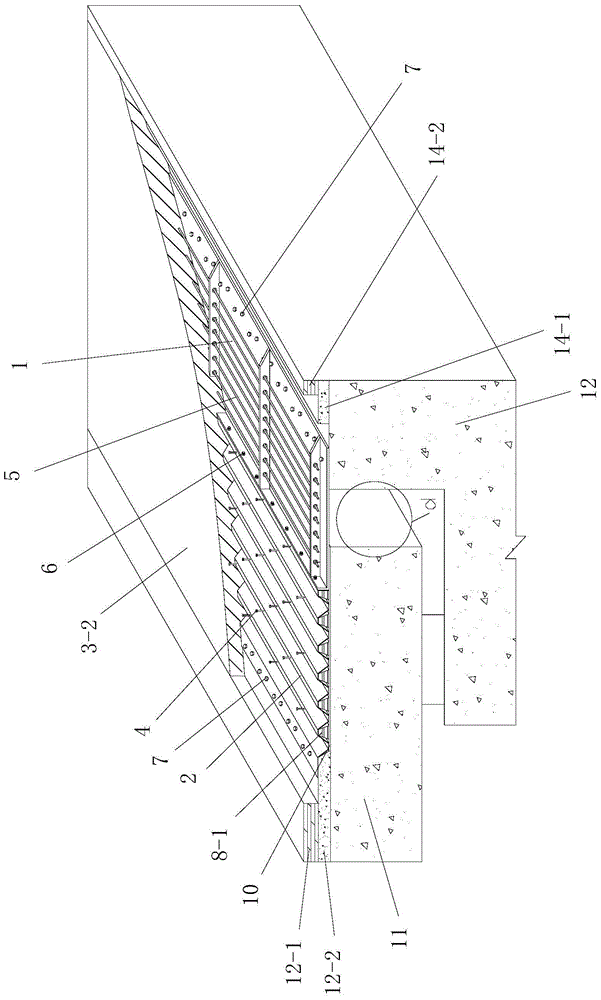

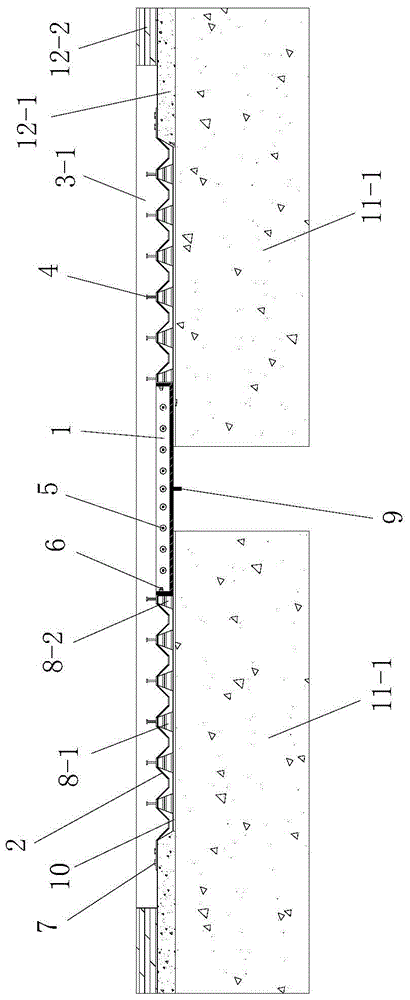

[0110] Such as Picture 1-1 , Figure 1-2 , diagram 2-1 and Figure 2-2 The shown bridge seamless expansion device includes the expansion device between the spans of the main girder arranged on the expansion joint of the main girder of the constructed bridge and the expansion device at the abutment arranged on the expansion joint of the abutment of the bridge constructed. The two ends of the main girder 11 of the constructed bridge are respectively supported on two abutments 12, and the main girder 11 is divided into M beam sections 11-1 from front to back along the longitudinal bridge direction, where M is a positive integer and M≥2 , each beam section 11-1 is paved with a bridge deck pavement structure; the upper outer side of the abutment 12 is paved with a road pavement layer and the upper inner side is an exposed section of the abutment; the main girder expansion joint It is the expansion joint left between two adjacent beam sections 11-1, each of the expansion joints ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com