Deep hole drill fixture

A technology for deep hole drilling and jigs, which is applied in the field of deep hole drilling jigs, and can solve problems such as easy deviation of drill bits and non-standard deep holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

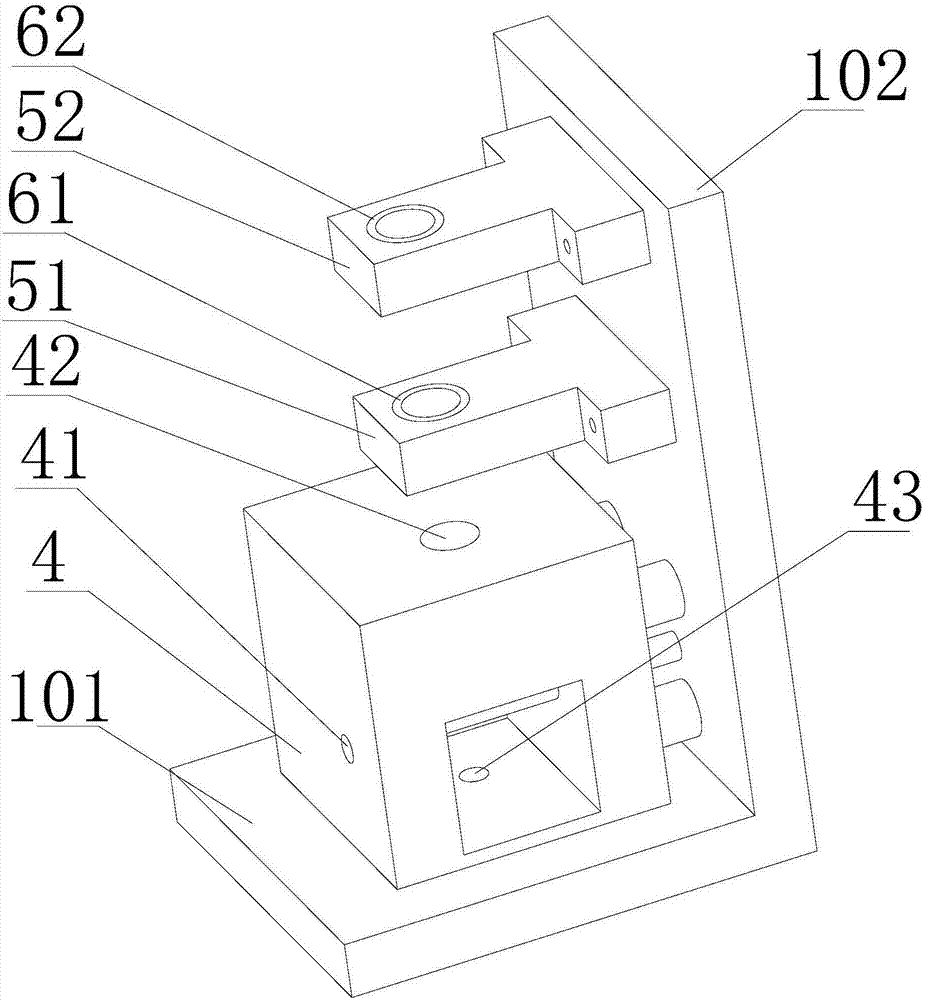

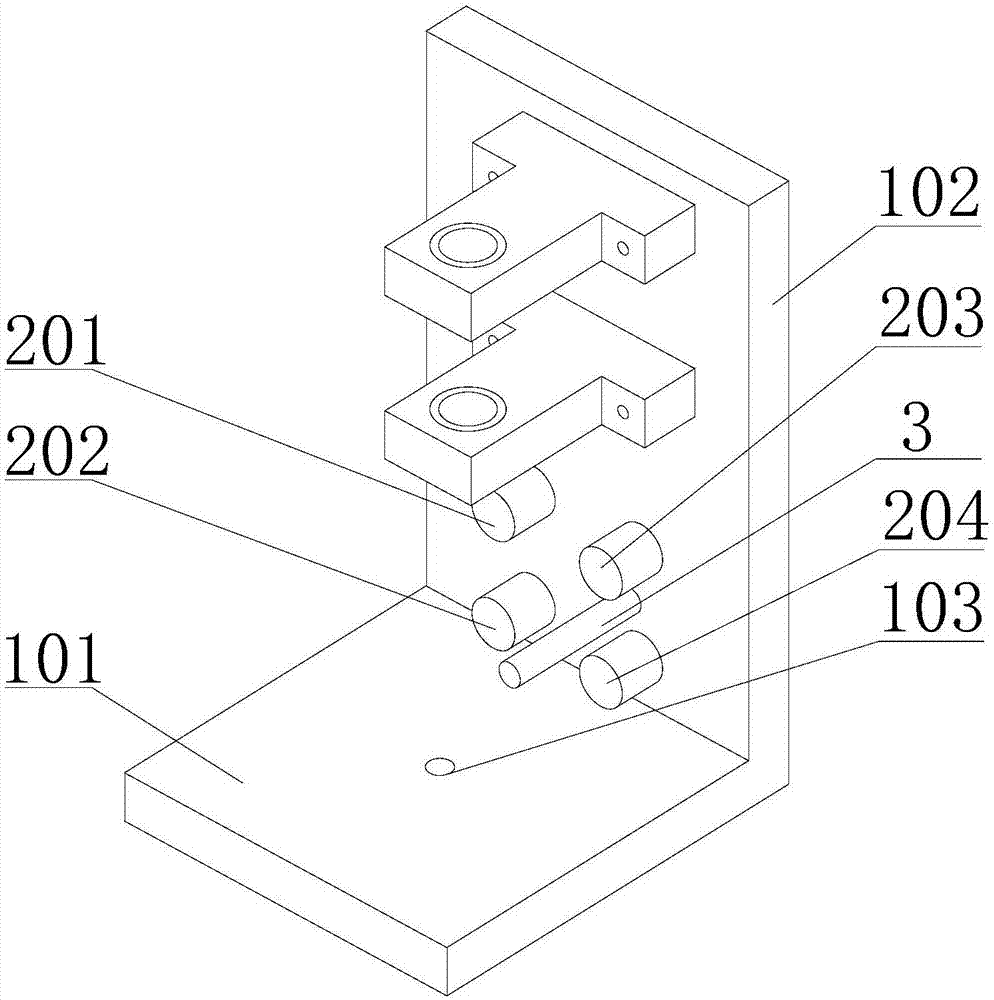

[0022] Such as Figure 1-2 As shown, a deep hole drilling jig includes a box body 4, a bushing seat, and a base 1. The box body 4 is provided with a deep hole 42, and a storage slot 44 is opened in the box body 4, and the workpiece to be processed is arranged in the storage slot 44. Inside, the position of the workpiece to be drilled is set on the central axis of the deep hole 42 . The workpiece to be processed is arranged in the box body 4, and the deep holes set in the box body have a guiding effect on the drilling.

[0023] The base 1 is an L-shaped structure, the box body 4 is arranged on the horizontal part 101 of the base, and the bush seat is arranged on the inner side of the vertical part 102 of the base.

[0024] A bushing hole is arranged on the bushing seat, and the bushing seat is arranged between the fixed end of the drill bit and the box body, and the central axis of the bushing hole coincides with the central axis of the deep hole on the box body. The bush sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com