A gripping apparatus for capping assemblies in container packaging machines

一种夹持装置、盖组件的技术,应用在用盖子将容器盖紧、瓶子/容器盖、包装等方向,能够解决经济性昂贵等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

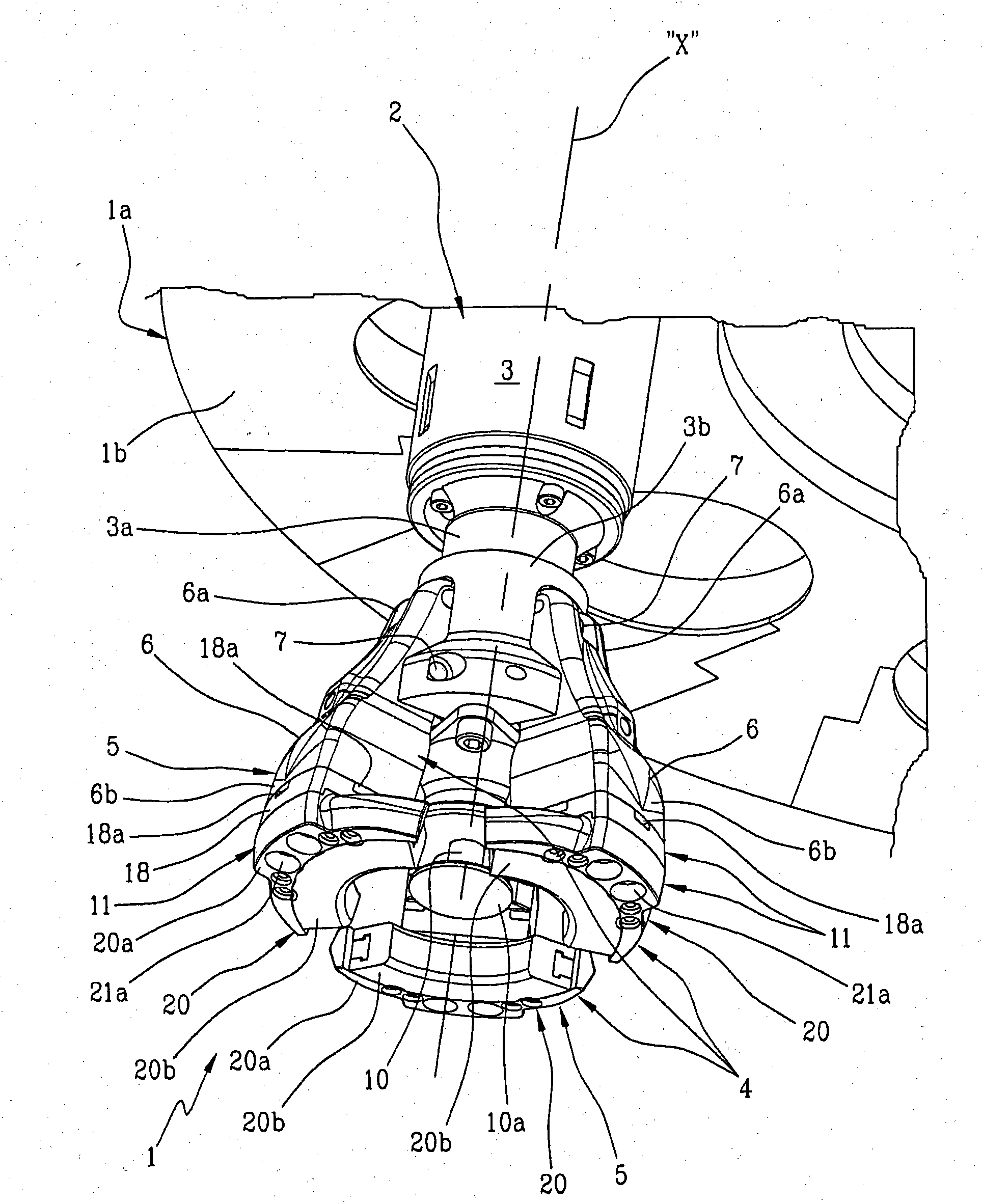

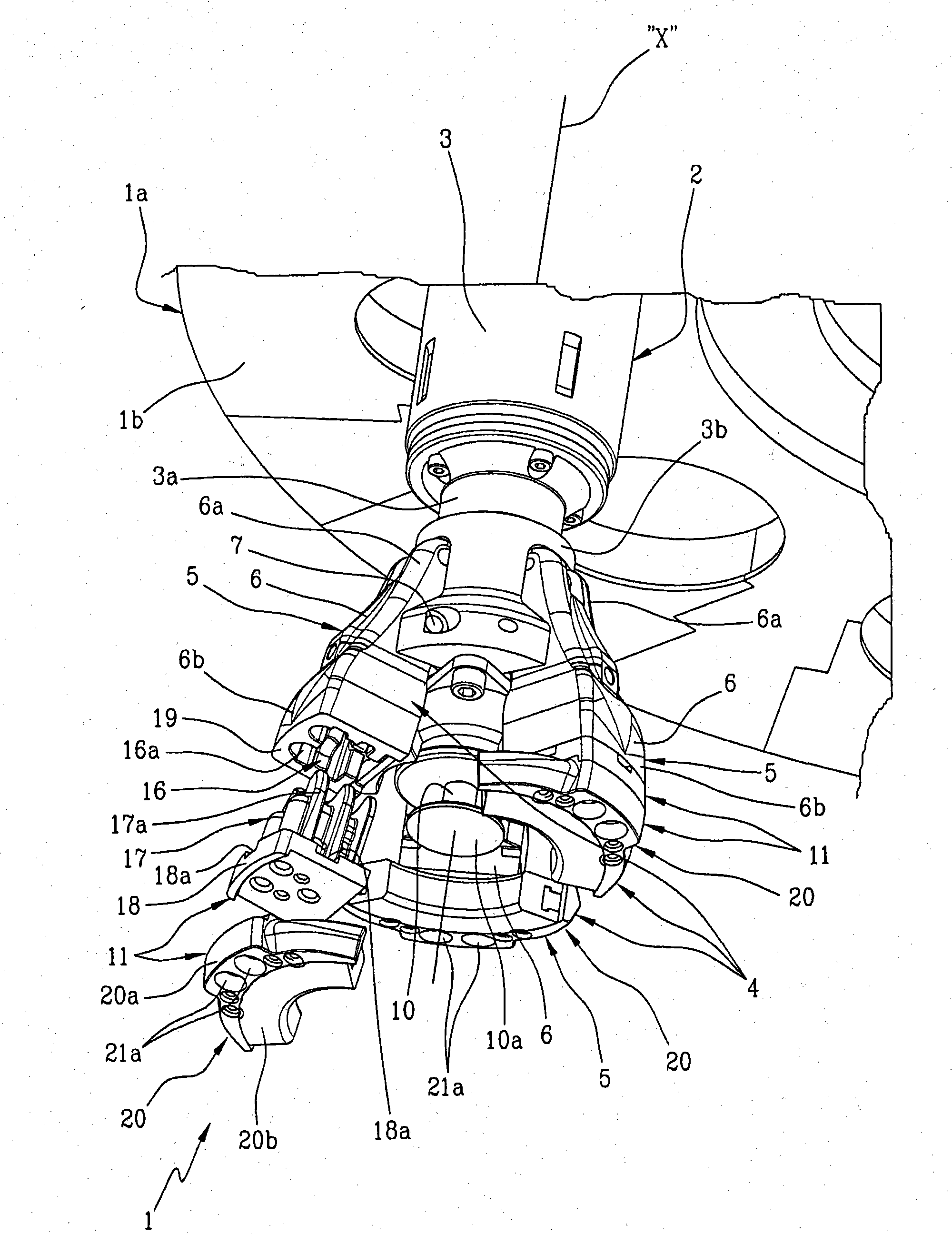

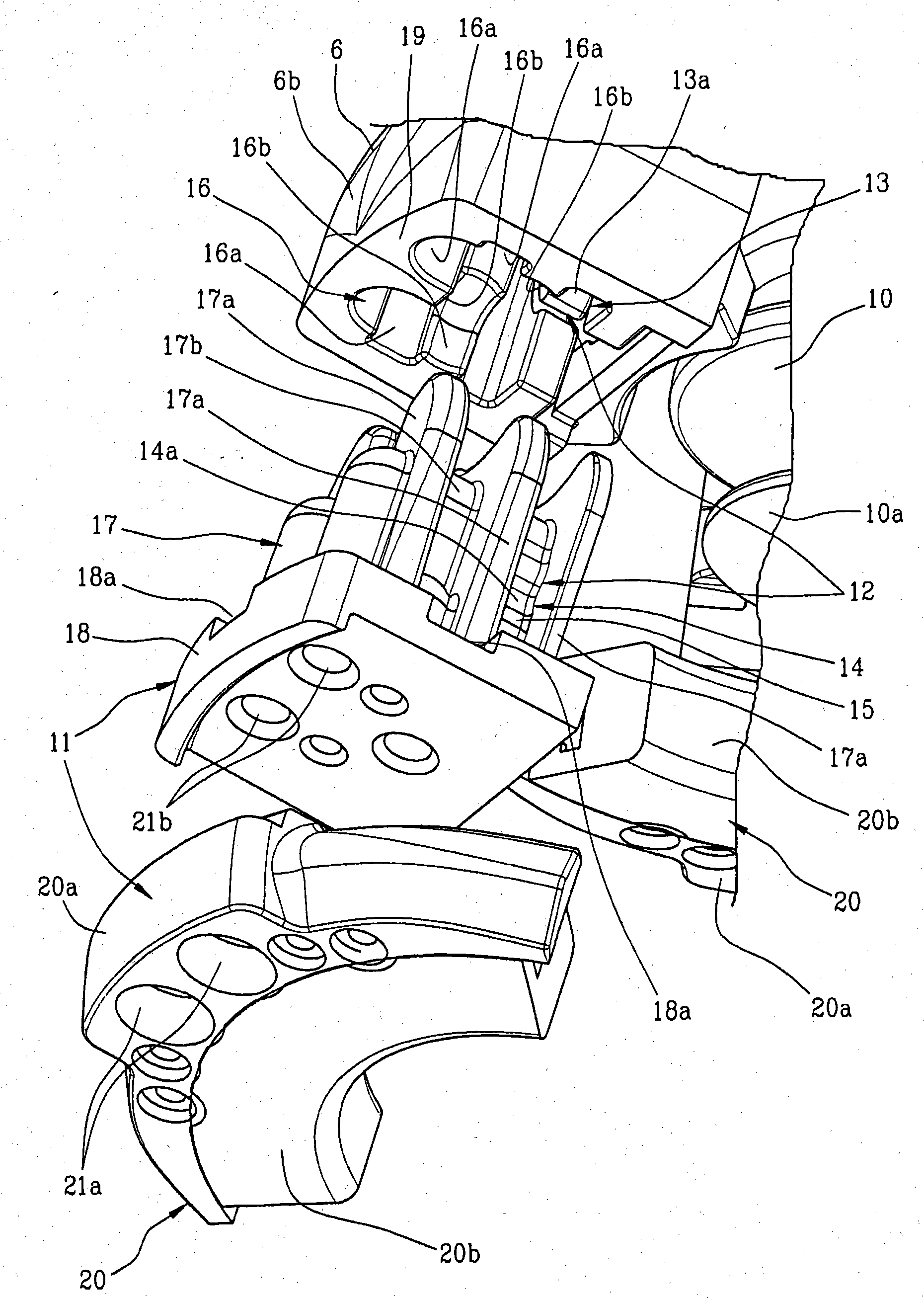

[0027] With reference to the figures of the accompanying drawings, the present invention relates to a holding device, generally designated by the reference numeral 1, for a capping assembly fitted to a capping unit of a machine, in particular for packaging containers. That capping assembly.

[0028] In general, containers designed to hold various types of products, such as liquid, viscous, creamy, gelatinous and / or powdery substances, are stored in a machine (not shown, in this embodiment) equipped with at least one capping unit 1a Filling and closing on a traditional machine in the example), in figure 1 with 2 Shown in is part of a capping unit 1a which automatically fits a lid or top (not shown) onto a corresponding container (not shown) ready for closure.

[0029] Such a capping unit 1a is usually equipped with a plurality of capping assemblies 2 ( figure 1 , 2 and 4), these capping assemblies 2 are mounted peripherally on a support structure or carousel 1b and are arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com