Apparatuses and methods for sterilising and filling components of packaging units, particularly bottles and/or caps

A technology of a sterilization device and equipment, applied in the field of bottle and/or cap filling and sterilization, can solve the problems of containers not suitable for producing caps, the efficiency of radiation penetration sterilization treatment, and the high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

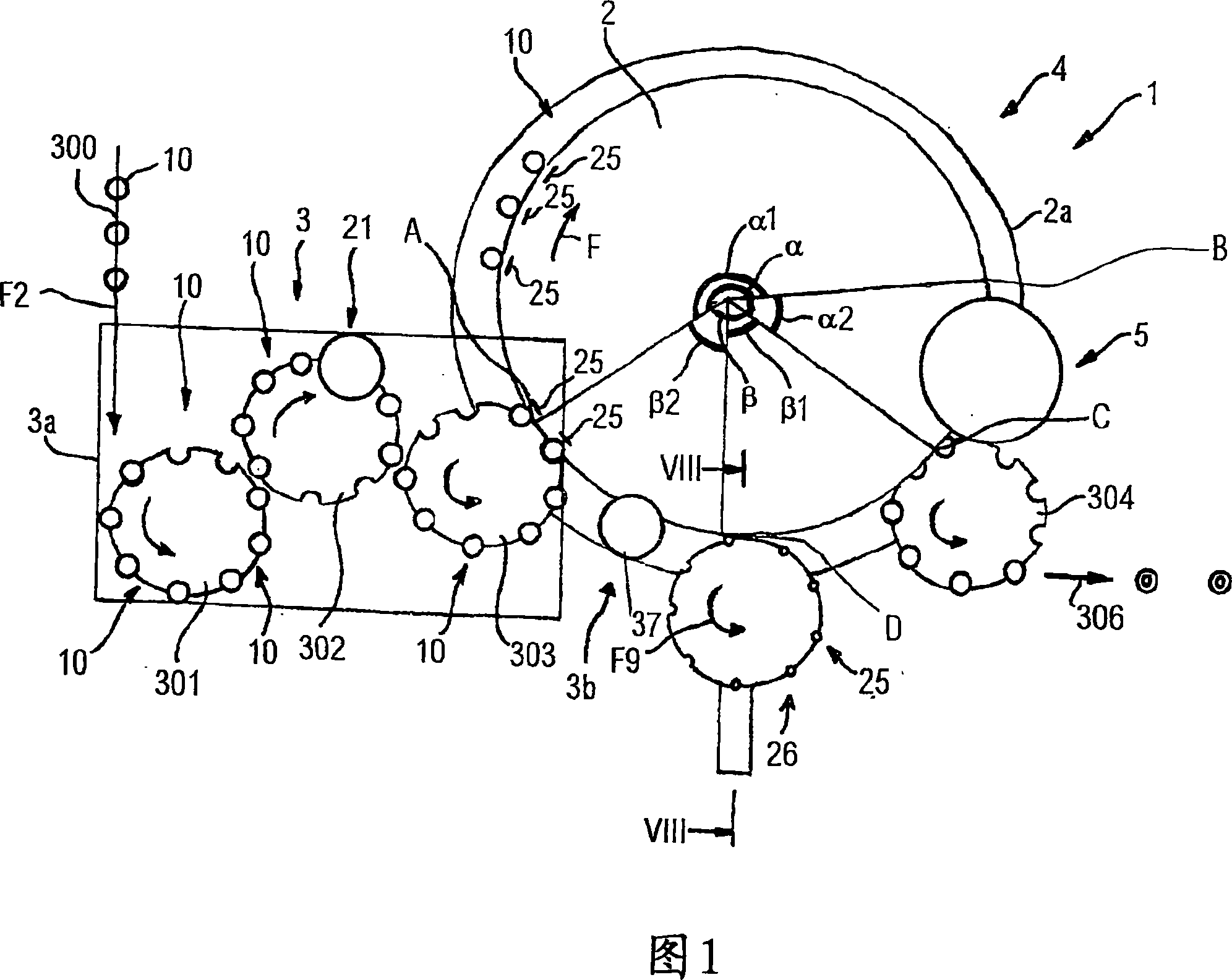

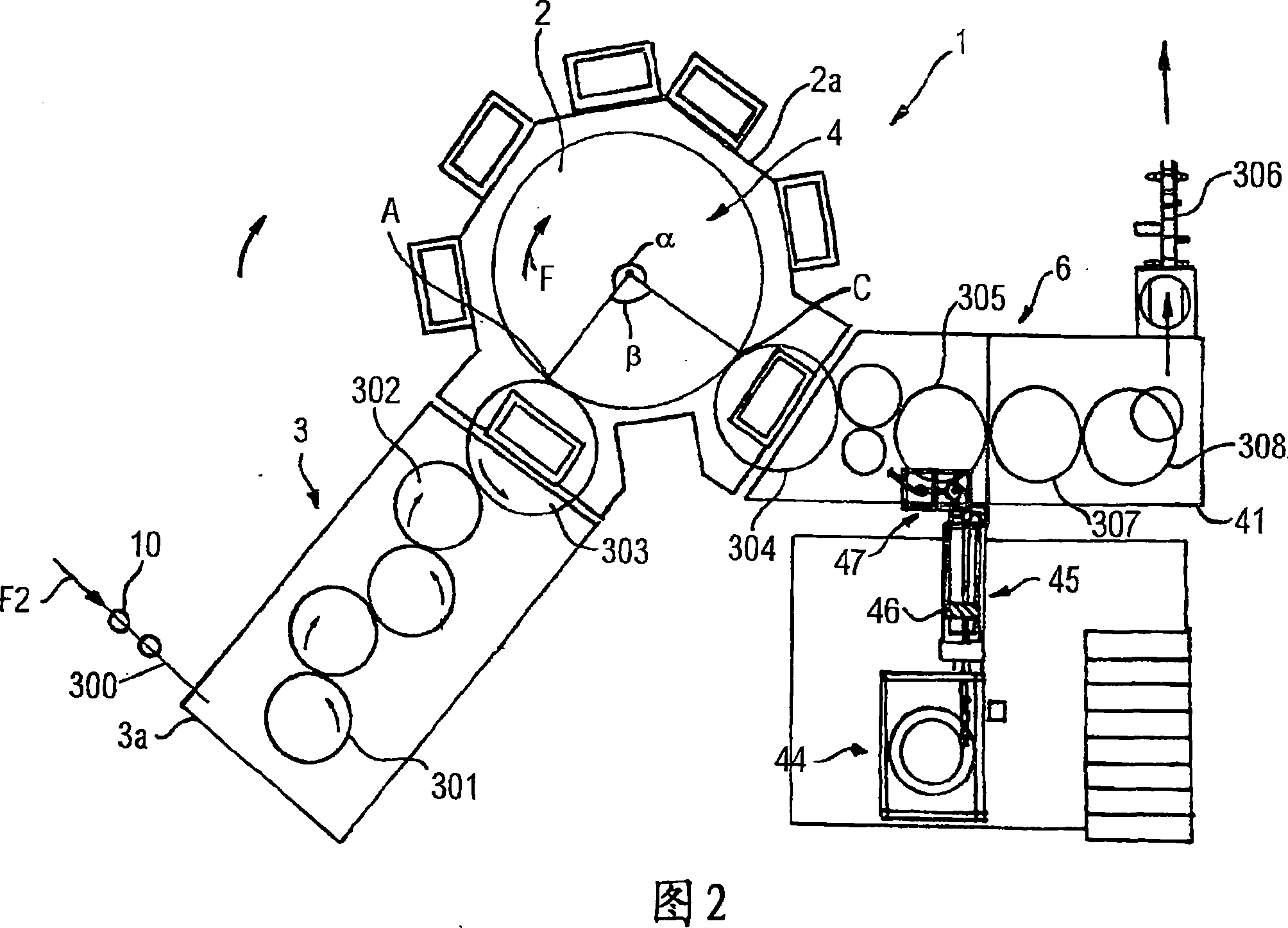

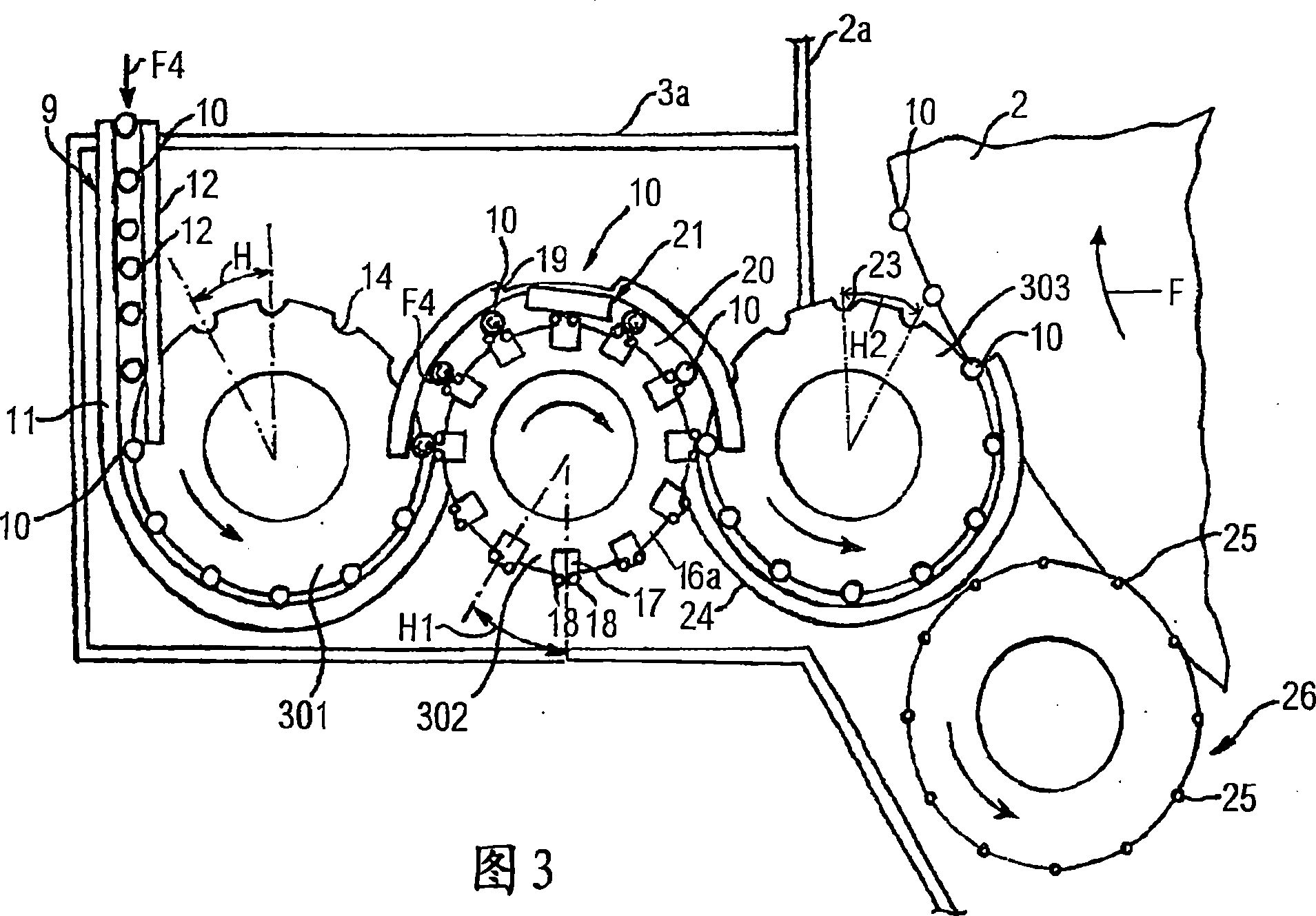

[0054] Referring to Figure 1, an apparatus 1 is shown for producing filled aseptic containers.

[0055] The device 1 comprises a carousel 2 delimited by walls 2a which have the function of isolating the carousel 2 from the outside to ensure that sterile conditions are maintained inside it. Upstream of the carousel 2 there is provided a sterilization zone 3 delimited by a wall 3 a, which is also sterile, where empty containers 10 are sterilized, in particular bottles coming from the supply line 300 . In the sterilization zone 3 are arranged a first transfer star-wheel 301, a second transfer star-wheel 302 and a third transfer star-wheel 303, which are rotatable about their respective vertical and interacting axes so as to pass through the spokes The container 10 is moved from the supply line 300 to the inlet A of the carousel 2 following the serpentine path of the sterilization device 21 .

[0056] The carousel 2 rotates in the direction indicated by the arrow F, in which rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com