Efficient antibacterial ABS plastic and preparation method thereof

An antibacterial material, ABS resin technology, applied in the field of antibacterial plastics, can solve the problems of easy overflow of antibacterial ability of organic molecules, reduce the mechanical properties of plastic products, and easy agglomeration, so as to achieve safe and effective preparation methods, increase the space structure of chain segments, evenly dispersed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

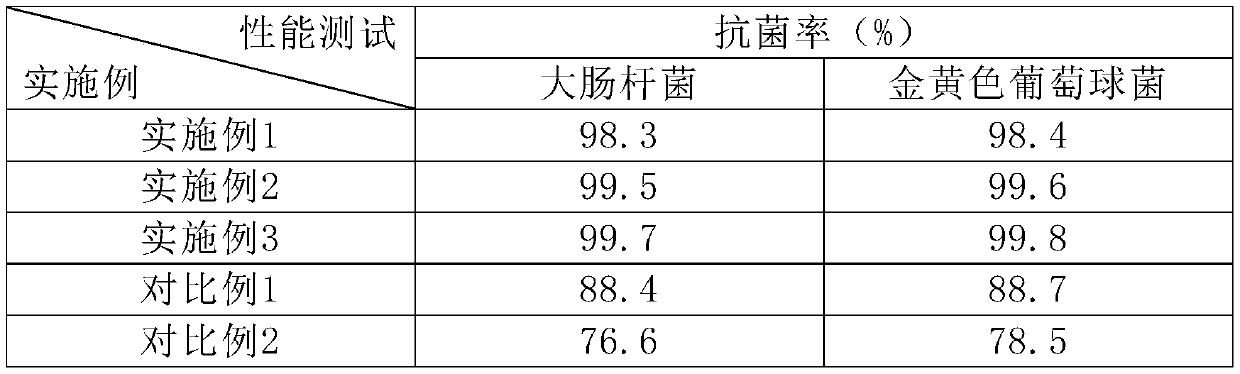

Examples

preparation example Construction

[0081] The preparation method of antibacterial material of the present invention is the method for making above-mentioned antibacterial material of the present invention, comprises the following steps:

[0082] (1) In the presence of a reactant, a silane coupling agent is used to pretreat the silver-loaded antibacterial agent irradiated by ultraviolet rays with a wavelength of 180 to 330 nm to obtain a pretreated antibacterial agent;

[0083](2) mixing the above-mentioned pretreated antibacterial agent with ABS resin and other auxiliary agents to obtain a mixed raw material;

[0084] (3) Extruding and granulating the dry blend to obtain antibacterial masterbatch;

[0085] (4) After the obtained antibacterial masterbatch is pressed into a thin sheet, it is thermally bonded with a pure ABS plate to obtain an antibacterial ABS composite material.

[0086] An example of the production method of the antibacterial material of the present invention will be described in detail below,...

Embodiment 1

[0101] The antibacterial material of Example 1 is prepared from the following components in parts by weight, 120 parts of ABS resin, 4 parts of silver-loaded antibacterial agent, 1.5 parts of γ-aminopropyltriethoxysilane, 10 parts of tetrahydrofuran, and 1 part of HAC , 0.5 parts of diffusing oil, 3 parts of ABS-g-MAH, 0.5 parts of antioxidant mixed with antioxidant 1076 and antioxidant 1010.

[0102] The preparation method of this antibacterial material comprises the following steps:

[0103] (1) Place the silver-loaded antibacterial agent on a clean mirror surface and spread it evenly, irradiate with ultraviolet light for 0.5h, and the irradiation distance is 40mm. After the irradiation is completed, add 4 parts of antibacterial agent to 10 parts of tetrahydrofuran solution containing 1.5 parts of γ-aminopropyltriethoxysilane, add HAC to adjust the pH value to 3.5, stir ultrasonically for 30 minutes, heat to 60 °C and then water bath After reacting for 2 hours, the obtained...

Embodiment 2

[0110] The antibacterial material of Example 2 is prepared from the following components in parts by weight, 130 parts of ABS resin, 6 parts of silver-loaded antibacterial agent, 2.5 parts of γ-aminopropyltriethoxysilane, 15 parts of tetrahydrofuran, and 2 parts of HAC , 0.6 parts of diffusing oil, 4 parts of ABS-g-MAH, 0.8 parts of antioxidant mixed with antioxidant 1076 and antioxidant 1010.

[0111] The preparation method of this antibacterial material comprises the following steps:

[0112] (1) Place the silver-loaded antibacterial agent on a clean mirror surface and spread it evenly, irradiate with ultraviolet light for 0.5h, and the irradiation distance is 40mm. After the irradiation is completed, add 6 parts of antibacterial agent to 15 parts of tetrahydrofuran solution containing 2.5 parts of γ-aminopropyltriethoxysilane, add HAC to adjust the pH value to 4.5, stir ultrasonically for 30 minutes, heat to 60°C and then water bath After reacting for 2 hours, the obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com