Complex cover material for refuse landfill and application method thereof

A landfill and covering material technology, which is applied in the field of solid waste treatment and disposal materials, can solve the problems of low odor removal rate and lack of nutrient elements, and achieve the effects of promoting the formation of aggregates, developing pore structure, and strengthening nitrogen fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

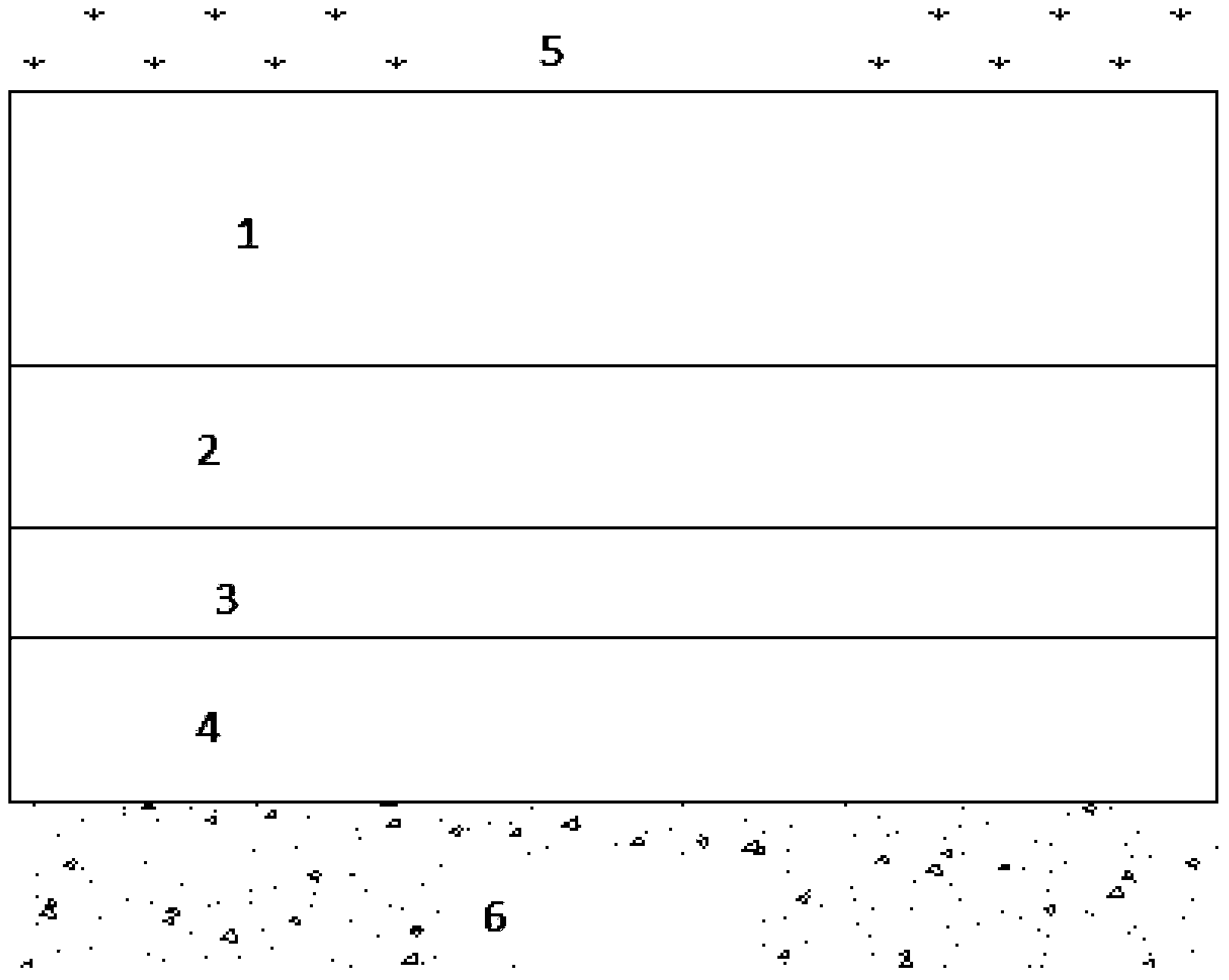

[0040] Embodiment 1, constructing a landfill covering system.

[0041] First, biochar, mineralized waste and incineration ash are mixed into a composite covering material with a mass ratio of biochar:mineralized waste:incinerated ash of 3:5:2, and the filling density of the composite covering material after mixing evenly 1.0g / cm 3 , the particle size range is 5-20mm, and the specific surface area is 180m 2 / g; the biochar is made by anaerobic / anoxic pyrolysis process using the remaining sludge of Minhang Sewage Treatment Plant at 550-750°C in anaerobic or anoxic state, and the mineralized waste is taken from old The Hong Kong landfill site fills up garbage (particle size <60mm) for 6-15 years. The incineration ash comes from a domestic waste incineration plant in Shanghai, and its furnace temperature is 800-950°C.

[0042] Then the composite covering material is compacted as a nutrient layer through a compactor, and the density of the composite covering material after compac...

Embodiment 2

[0044] Example 2, constructing a landfill covering system.

[0045] First, biochar, mineralized waste and incineration ash are mixed into a composite covering material with a mass ratio of biochar:mineralized waste:incinerated ash of 4:5:1, and the filling density of the composite covering material after mixing is uniform 0.6g / cm 3 , the particle size range is 5-20mm, and the specific surface area is 280m 2 / g; the biochar is made by anaerobic / anoxic pyrolysis process using the remaining sludge of Minhang Sewage Treatment Plant at 550-750°C in anaerobic or anoxic state, and the mineralized waste is taken from old The Hong Kong landfill site fills up garbage (particle size <60mm) for 6-15 years. The incineration ash comes from a domestic waste incineration plant in Shanghai, and its furnace temperature is 800-950°C.

[0046] Then the composite covering material is compacted as a nutrient layer through a compactor, and the density of the composite covering material after compa...

Embodiment 3

[0048] Embodiment 3, constructing a landfill covering system.

[0049] Firstly, biochar, mineralized waste and incineration ash are mixed into a composite covering material with a mass ratio of biochar:mineralized waste:incinerated ash of 4:4:2, and the filling density of the composite covering material after mixing evenly 0.7g / cm 3 , the particle size range is 5-20mm, and the specific surface area is 260m 2 / g; the biochar is made by anaerobic / anoxic pyrolysis process using the remaining sludge of Minhang Sewage Treatment Plant at 550-750°C in anaerobic or anoxic state, and the mineralized waste is taken from old The Hong Kong landfill site fills up garbage (particle size <60mm) for 6-15 years. The incineration ash comes from a domestic waste incineration plant in Shanghai, and its furnace temperature is 800-950°C.

[0050] Then the composite covering material is compacted as the base layer through a compactor, and the density of the composite covering material after compac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Filling density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com