Equipment for automatically peeling, decoring and splitting fruit and method for automatically controlling equipment

A kind of fruit and automatic technology, which is applied in the direction of fruit pitting device, electrical program control, program control in sequence/logic controller, etc. It can solve the problems of increasing the process, damaging the pulp, reducing the quality of the pulp, etc., and achieve the effect of increasing the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

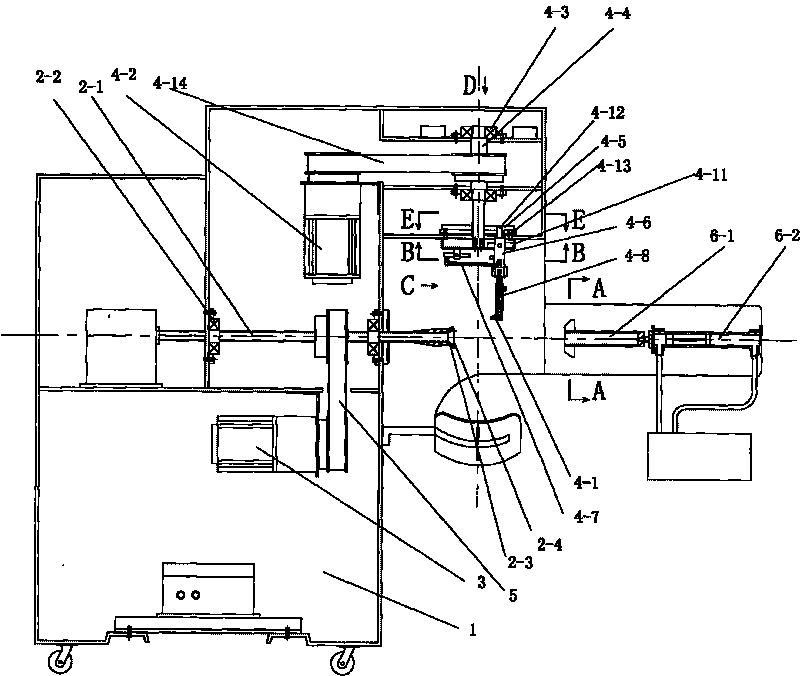

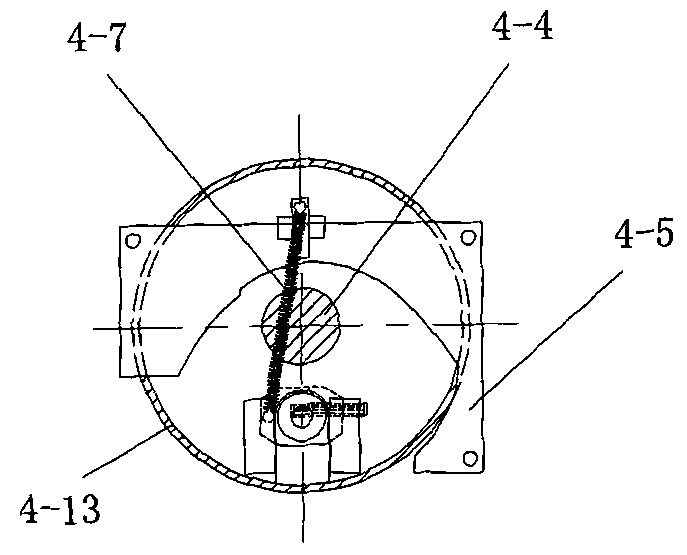

[0012] Specific implementation mode one: the following combination figure 1 , figure 2 and Figure 5This embodiment will be specifically described. It consists of a frame body 1, a main shaft assembly, a main shaft rotating motor 3, a No. 1 belt transmission mechanism 5, a peeling knife assembly, a core removal and splitting knife insertion assembly, a gas control circuit and a control circuit. The main shaft assembly includes Main shaft 2-1, main shaft bearing 2-2 and suction nozzle 2-3, described main shaft 2-1 is a hollow shaft, the end of main shaft 2-1 front end cavity is fixed with suction nozzle 2-3, main shaft rotating motor 3 The No. 1 belt transmission mechanism 5 is connected to the outer surface of the main shaft 2-1 to drive it. The main shaft 2-1 is arranged on the frame body 1 through the main shaft bearing 2-2, and the paring knife assembly is arranged on the suction nozzle. On the frame body 1 above the 2-3, the core-taking and splitting knife inserting as...

specific Embodiment approach 2

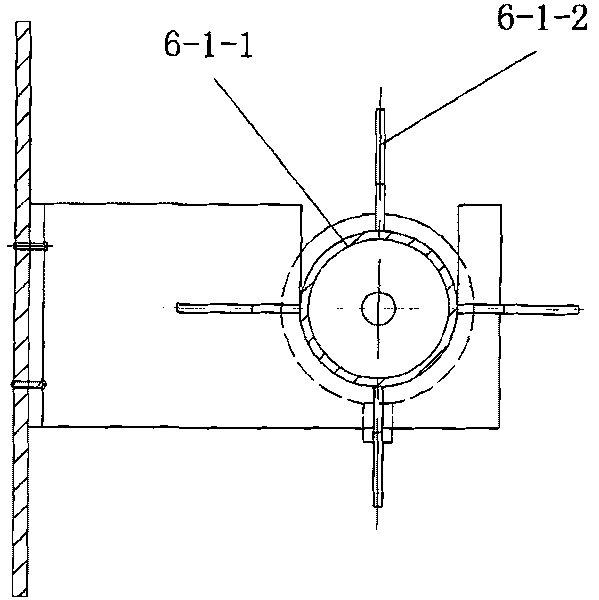

[0017] Specific implementation mode two: the following combination figure 1 This embodiment will be specifically described. The difference between this embodiment and Embodiment 1 is that it also includes a plurality of short steel needles 2-4, which are arranged on the inner surface of the suction nozzle 2-3 and arranged evenly along its circumferential direction. All the short steel needles 2-4 are towards the slotting knife 6-1. In this way, when the fruit is sucked on the suction nozzle 2-3, the short steel needle 2-4 is also shallowly inserted on the fruit, so that when peeling, the fruit is sucked by the suction nozzle 2-1 under the action of the cutter head 4-1. 3 The surface slips and rotates. The purpose of inserting fruit in this embodiment is anti-skid, only plays auxiliary fixing effect, so inserting fruit is very shallow.

specific Embodiment approach 3

[0018] Specific implementation mode three: the following combination Figure 9 This embodiment will be specifically described. The difference between this embodiment and Embodiment 1 is that it also includes an air spray gun 20 and a manual valve 21, the inlet port of the manual valve 21 is connected to the gas outflow end of the gas storage tank 8-1, and the gas outlet port of the manual valve 21 is connected to the gas injection port. The air intake port of the gun 20. With such arrangement, the operator can control the air spray gun 20 through the manual valve 21, and use the air spray gun 20 to flush the cavity of the main shaft 2-1 and the like when the device of the present invention is shut down for rest.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com