Branch pruning machine for green belts

A technology for pruning machines and green belts, which is applied in the direction of agricultural machinery and tools, cutting tools, cutting equipment, etc., can solve the problems of missed pruning, low strength, and affecting cutting efficiency, so as to reduce missed pruning branches and improve pruning efficiency. The effect of increasing shear strength and improving shear efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

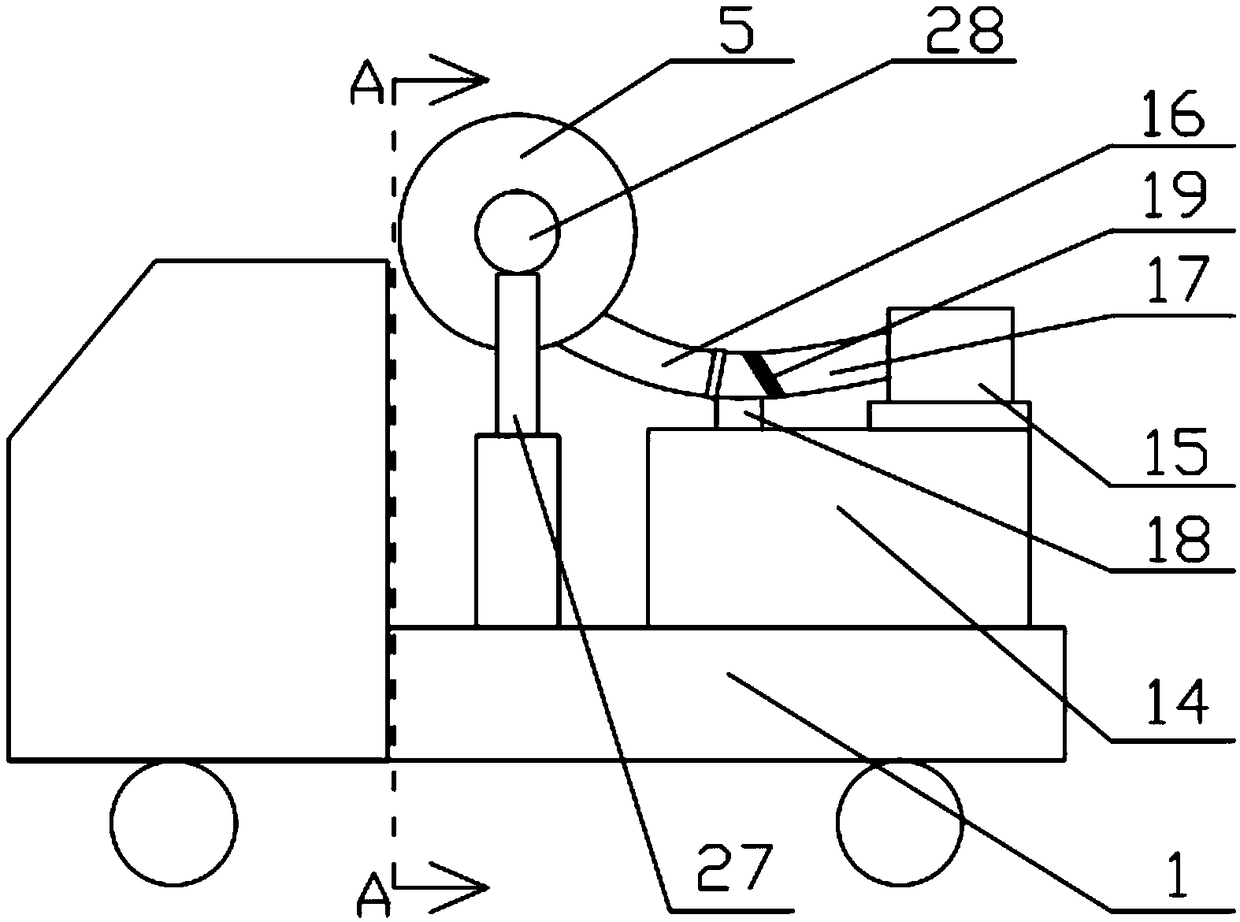

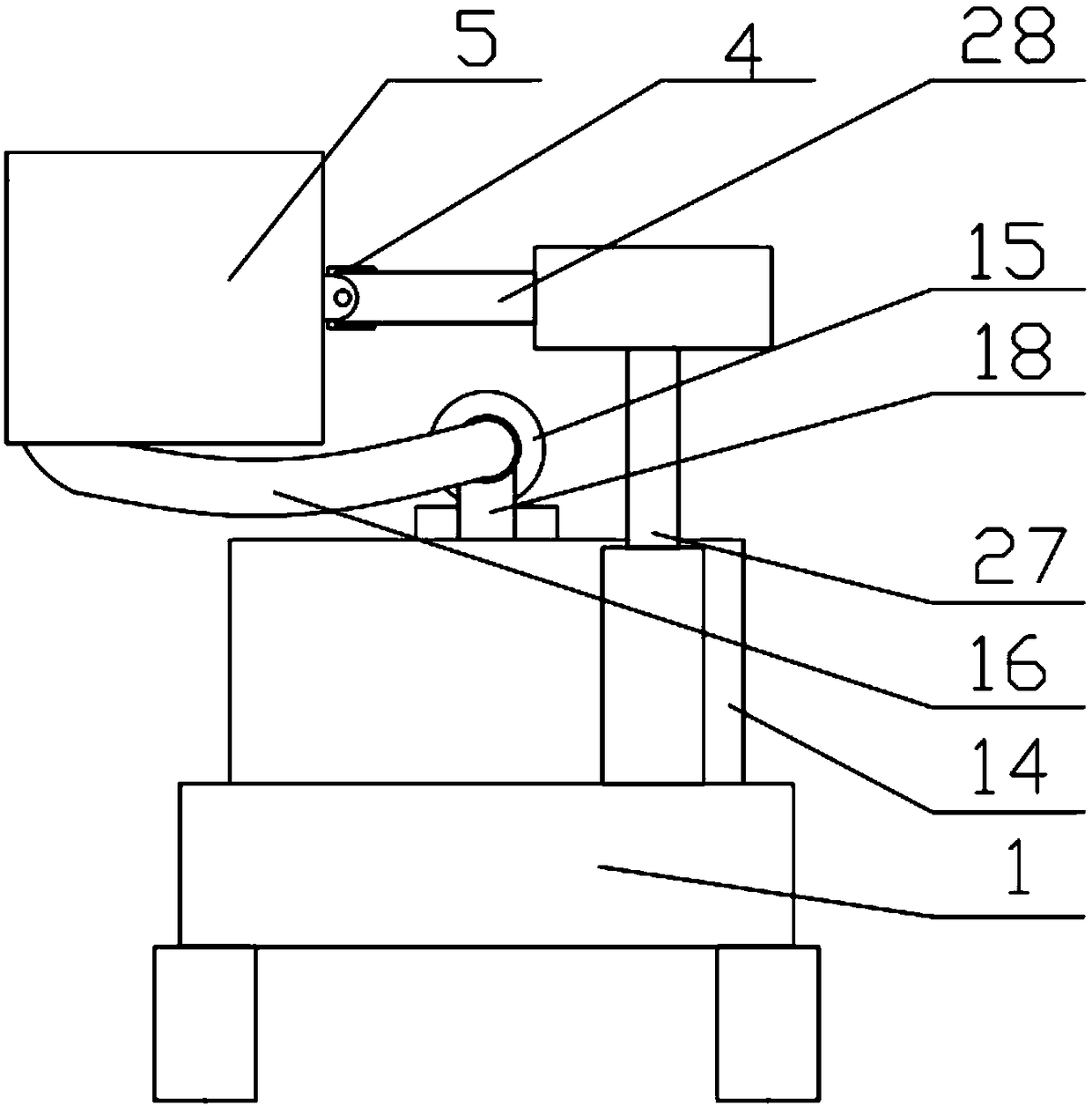

[0032] like figure 1 and figure 2 The shown green belt pruning machine includes a carrier vehicle 1 and a pruning device. The pruning device includes a shearing mechanism, an adjustment mechanism and a branch recovery mechanism. The adjustment mechanism is provided on the carrier vehicle 1 and adjusts. The action end of the mechanism is connected to the shearing mechanism;

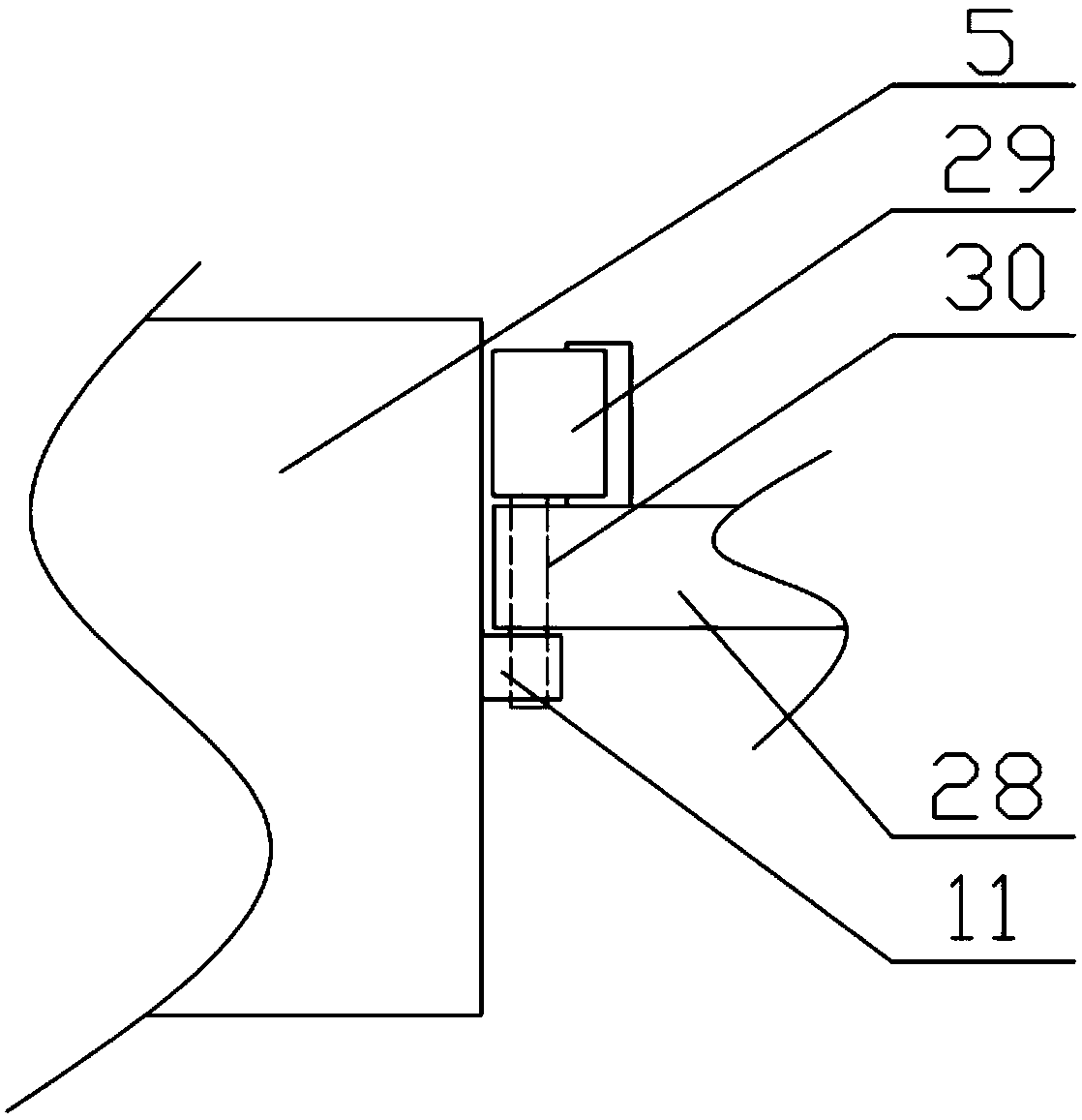

[0033] like Figure 4 and Figure 5 As shown, the shearing mechanism includes a main cutter wheel 2 and at least three auxiliary cutter wheels 3 ( Figure 5 There are four auxiliary cutter wheels 3), and the cutting motor 4 and the transmission assembly for driving the main cutter wheel 2 and the auxiliary cutter wheel 3, and a protective cylinder with a cylindrical structure is provided outside the shearing mechanism. cover 5; as Image 6 As shown, the main cutter wheel 2 and the auxiliary cutter wheel 3 both include a wheel ring sleeve 6 and a shearing blade 7 provided therein, and the main cutter wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com