All-directional planetary ball mill

A planetary ball mill, all-round technology, applied in grain processing, etc., can solve problems such as unavoidable vibration, equipment leakage, injury, carbon plug dislocation, etc., to achieve the effect of improving ball mill production efficiency, high safety performance, and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

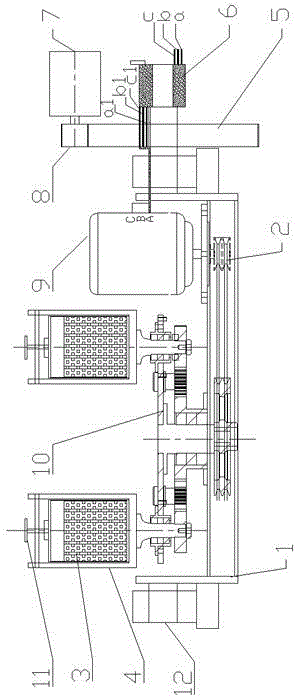

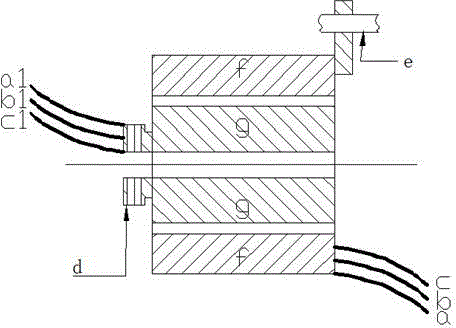

[0019] Example 1, such as figure 1 , 2 As shown, an omnidirectional planetary ball mill includes a rotating frame 1, a transmission motor 9, a planetary transmission mechanism 10, a grinding tank 12, and a grinding tank seat 13; the transmission motor 9 drives the planetary transmission mechanism 10 through a pulley 2, and the planetary transmission The mechanism 10 drives the grinding tank 3 to rotate through the grinding tank seat 4; the rotating frame 1 fixes the planetary transmission mechanism 10, and is supported by the bearing seats 12 at both ends. The motor gear 8 and the large gear 5 are driven to make the upper mechanism of the entire rotating frame 1 perform a 360° flip movement, which is characterized in that it also includes a through-hole slip ring 6 placed at the other end of the rotating frame 1 shaft. The through-hole slip ring includes The stator f and the rotor g, the three terminal wires A, B, and C of the transmission motor 9 are respectively connected w...

Embodiment 2

[0020] Example 2, such as figure 1 , 2 As shown, on the basis of Embodiment 1, the connection method of the through-hole slip ring 6 and the transmission motor 9 is as follows: first, the input power is connected to the stator wires a, b, and c, and the rotor wires a1, b1, and c1 lead from the large gear 5. Go through the counterbore of the main shaft on the rotating frame 1, and connect the wires A, B, and C of the transmission motor 9 terminals to conduct, and the set screw d is used to pass through the slip ring inner hole and cooperate with the rotating frame shaft to prevent rotation; the slip ring The stator anti-rotation pin shaft e prevents the through-hole slip ring stator from rotating.

Embodiment 3

[0021] Embodiment 3, on the basis of Embodiment 1, the number of the grinding pots 3 is 4, the grinding pot seat 4 and the grinding pot 3 are fixed by the clamping device 11, and the grinding pot seat 4 and the planetary mechanism 10 are fixed by a tapered shaft or a flange form connection.

[0022] The outstanding advantage of the present invention is that the mechanism on the rotating frame 1 can be ball milled and mixed in any angle of 360°. Due to the application of the through-hole slip ring in the present invention, the omnidirectional planetary ball mill solves the problem of traditional planetary ball mill grinding tanks. After a certain ball milling time, the internal materials sink to the bottom, agglomerate, stick to the wall, etc., and at the same time meet the nano-level requirements required by customers, saving costs. At the same time, it also solves the following safety problems in the use of the original collector ring in the traditional ball mill: the origina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com