Tool for depositing coating on multi-arc ion plating equipment and usage method thereof

A multi-arc ion plating and coating technology, applied in the direction of ion implantation plating, metal material coating process, coating, etc., can solve the problems of long processing cycle of parts, expensive alloy ingots, low deposition rate, etc., and achieve the goal of using The method is simple, the structure is simple, and the effect is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

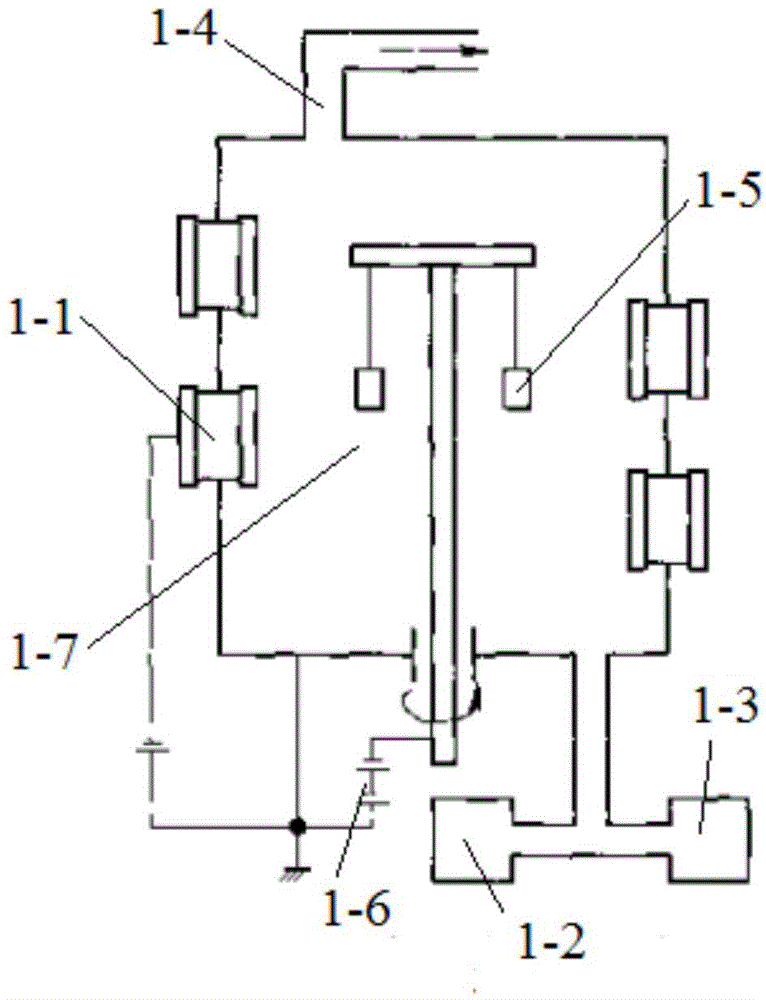

[0039] In this embodiment, the workpiece is a turbine rotor blade. Place the intake side of the two turbine working blades inward in the positioning box, and place it on the first floor of the equipment. After the coating process is carried out according to the process parameters in the present invention, the outer surface of the airfoil and the upper surface of the edge plate are coated, and the turbine working blade is obtained with effective protection for the tenons.

[0040] The specific usage of tooling is as follows:

[0041] Step 1, cleaning: clean the turbine working blades and tooling with acetone, and prepare for clamping. Cleaning is to prevent the parts from being polluted and affecting the adhesion of the coating.

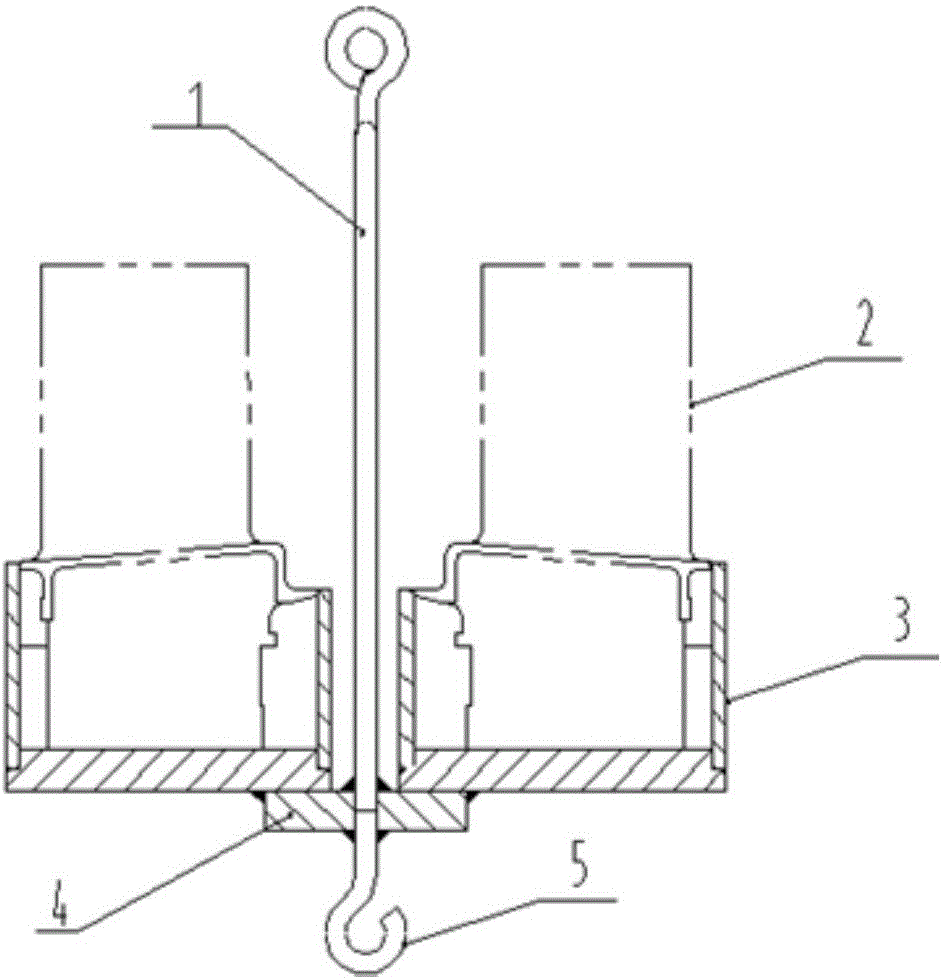

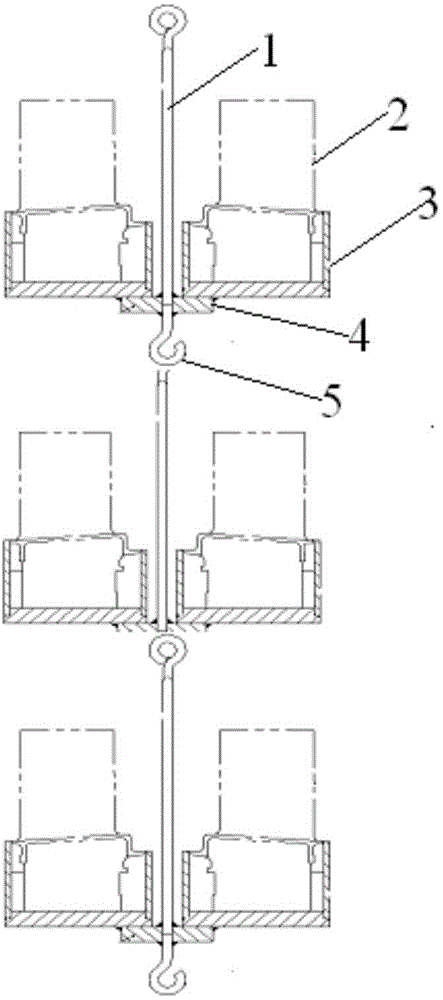

[0042] Step 2, clamping: put the tenons of the turbine working blades into the positioning box, and connect them into a string through the hook.

[0043] Step 3, apply the coating, the specific process is:

[0044] Furnace loading: Connect the str...

Embodiment 2

[0052] In this embodiment, the workpiece is a turbine rotor blade. Place the two turbine working blades with the inlet side facing inwards in the positioning box, and place them on the second floor of the equipment. After the coating treatment is carried out according to the corresponding process parameters, the outer surface of the airfoil and the upper surface of the edge plate are coated, and the working blade of the turbine is obtained, and the tenons are effectively protected.

[0053] The specific usage of the tooling is as follows:

[0054] Step 1, cleaning: clean the turbine working blades and tooling with acetone, and prepare for clamping. Cleaning is to prevent the parts from being polluted and affecting the adhesion of the coating.

[0055] Step 2, clamping: put the tenons of the turbine working blades into the positioning box, and connect them into a string through the hook.

[0056] Step 3, coating coating: the specific process of the coating coating is:

[00...

Embodiment 3

[0065] The tooling of this embodiment can effectively ensure that the outer surface of the blade body and the upper surface of the edge plate are coated with a uniform thickness, and the tenon needs to be protected.

[0066] In this embodiment, the workpiece is a turbine rotor blade. Place the intake side of the two turbine working blades inward in the positioning box, and place it on the third floor of the equipment. After the coating treatment is carried out according to the corresponding process parameters, the outer surface of the airfoil and the upper surface of the edge plate are coated, and the working blade of the turbine is obtained, and the tenons are effectively protected.

[0067] The specific usage of the tooling is as follows:

[0068] Step 1, cleaning: clean the turbine working blades and tooling with acetone, and prepare for clamping. Cleaning is to prevent the parts from being polluted and affecting the adhesion of the coating.

[0069] Step 2, clamping: pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com