Multi-station sweeping equipment

A multi-station and equipment technology, applied in the field of machinery, can solve problems such as inability to realize speed, steering control, complex structure of transmission control, and affect processing effect, etc., and achieve good support effect, improved sweeping efficiency, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

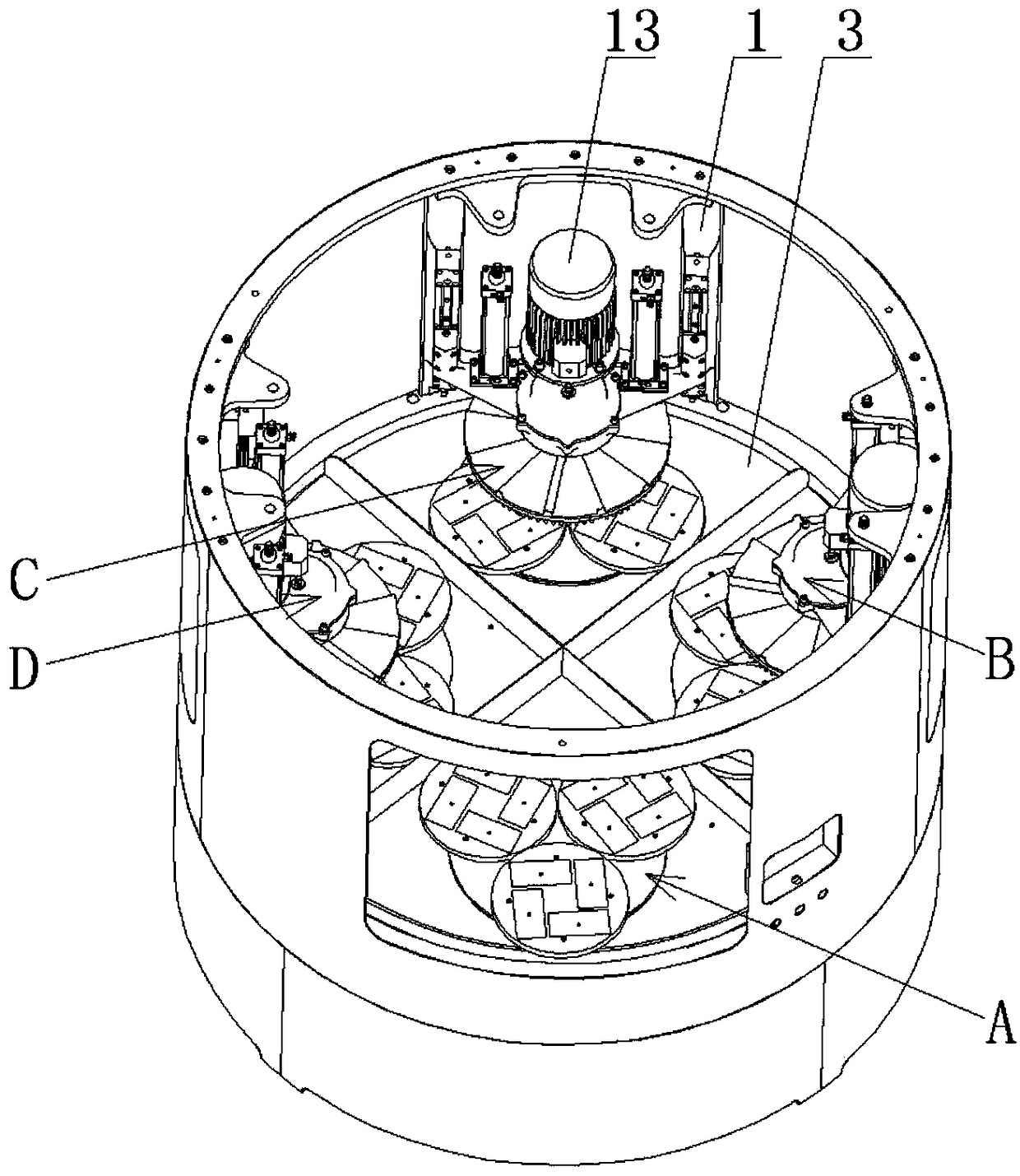

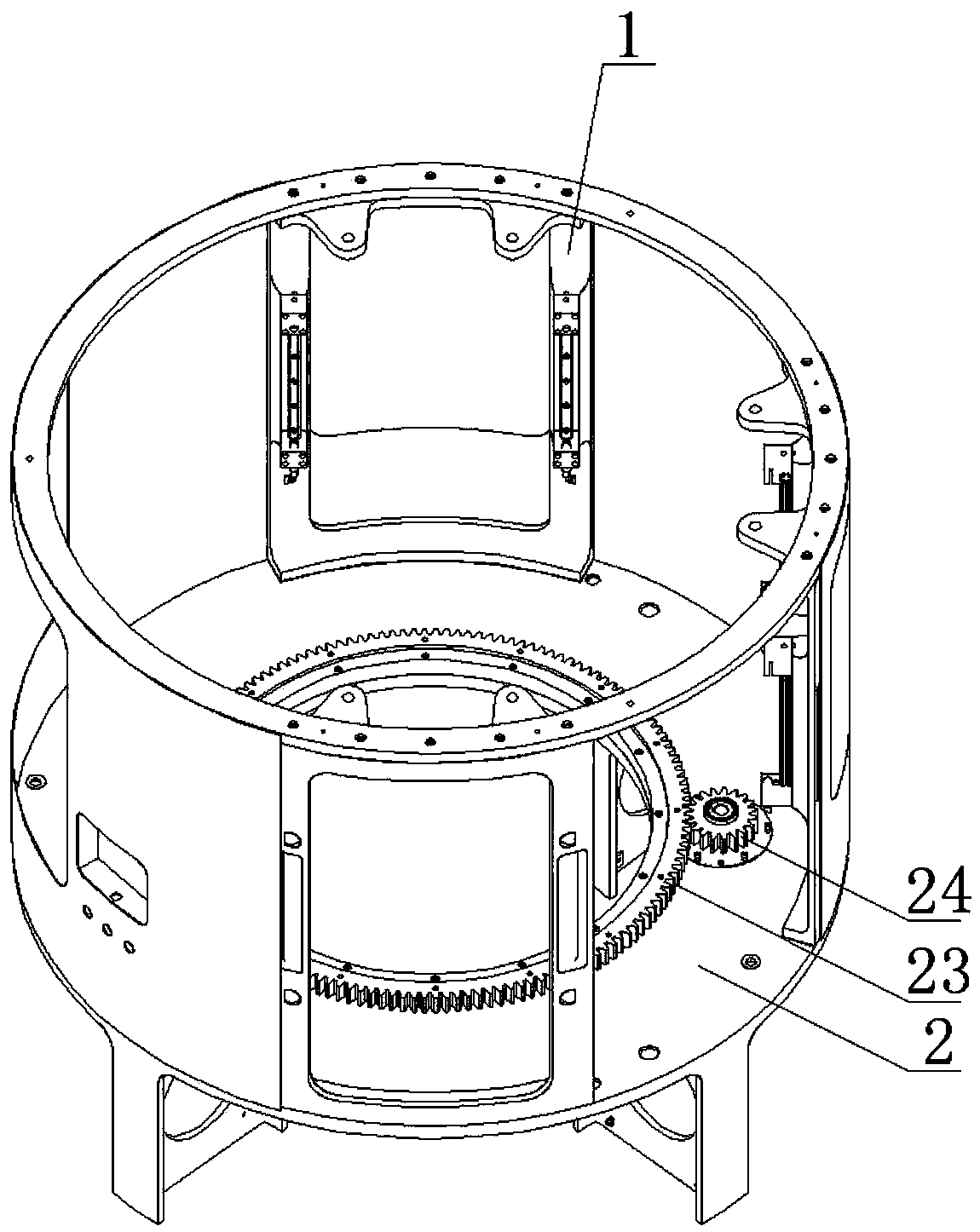

[0041] Such as figure 1 The multi-station sweeping equipment shown includes a bed 2 with a frame 1 on it and a plurality of positioning components for positioning workpieces, one of which is located at the loading and unloading station A, and the rest of the positioning components are located at the processing station at the workstation. Specifically, such as figure 1 The multi-station light-sweeping equipment shown has 4 stations, each station is equipped with a positioning component, and the 4 stations are distributed in a circular array, followed by the loading and unloading station A and the first processing station B. The second processing station C and the third processing station D. For example, the first processing station B is a rough grinding station, the second processing station C is a middle-magic station, and the third processing station D is a fine grinding station.

[0042] Such as figure 1 As shown, the frame 1 has a number of scanning components correspon...

Embodiment 2

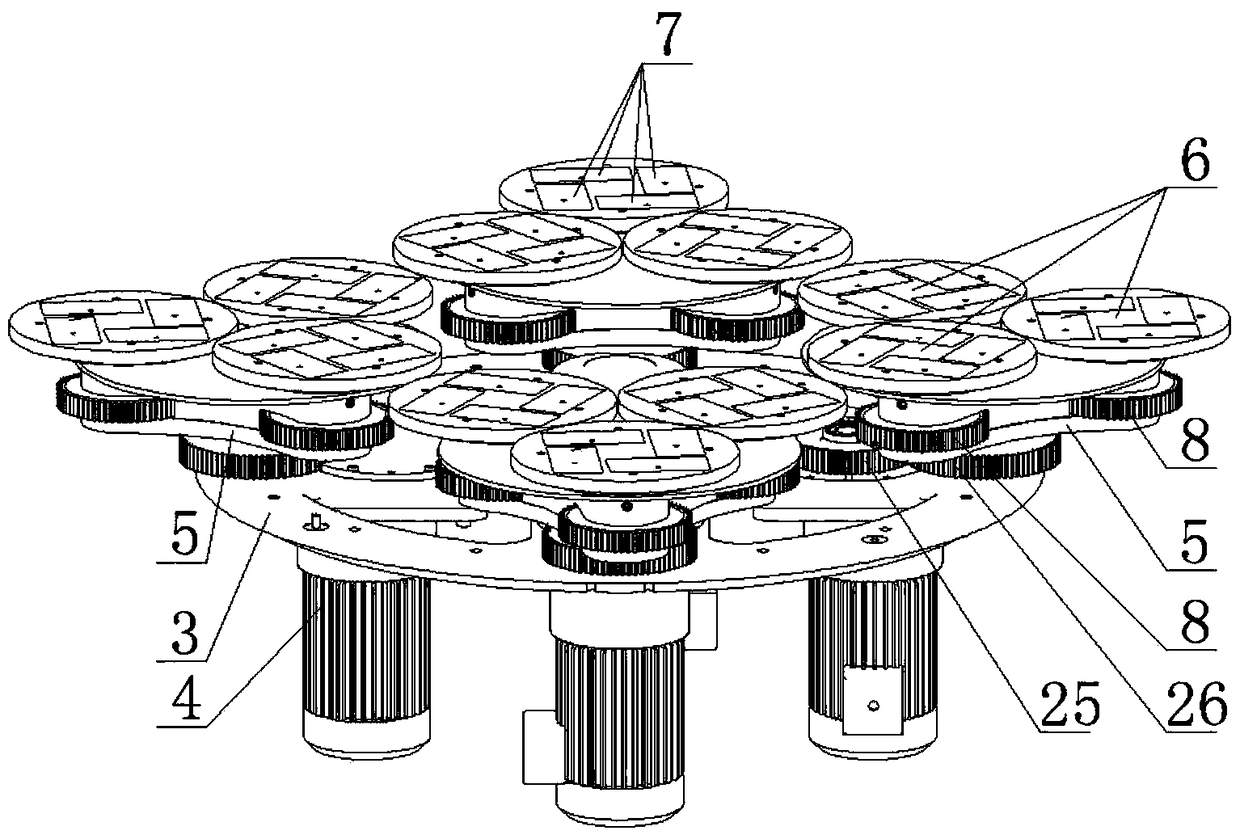

[0065] The structural principle of this embodiment is basically the same as that of Embodiment 1, the difference is that, as Figure 9 As shown, the output shaft of the motor is fixedly connected with a gear one 25 located above the rotating seat 3, and the power shaft 34 is coaxially fixed with a gear two 26 that is meshed with the gear one 25. When the output shaft of the motor rotates , drive the first gear 25 to rotate, and the first gear 25 drives the second gear 26 to drive the power shaft 34 to rotate.

[0066] Wherein, the power shaft 34 is sleeved with a planetary carrier 5, and the power shaft 34 is fixedly connected with an internal gear 36 above the planetary carrier 5, and the internal gear 36 meshes with the planetary gear 8 provided on the rotating shaft 35, and The outer ring of the planetary gear 8 is provided with a sun gear. When gear two 26 rotates, it drives the power shaft 34 to rotate, and the power shaft 34 drives the internal gear 36 to rotate, and th...

Embodiment 3

[0068] The structural principle of this embodiment is basically the same as that of Embodiment 1, the difference is that there are 3 stations in this embodiment: loading and unloading station A, first processing station B and second processing station C , wherein the first processing station B is a rough grinding station, and the second processing station C is a fine grinding station.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com