Dual heating vapor phase epitaxial growth system

An epitaxial growth, dual heating technology, applied in crystal growth, single crystal growth, chemical reactive gas and other directions, to improve the temperature control accuracy and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

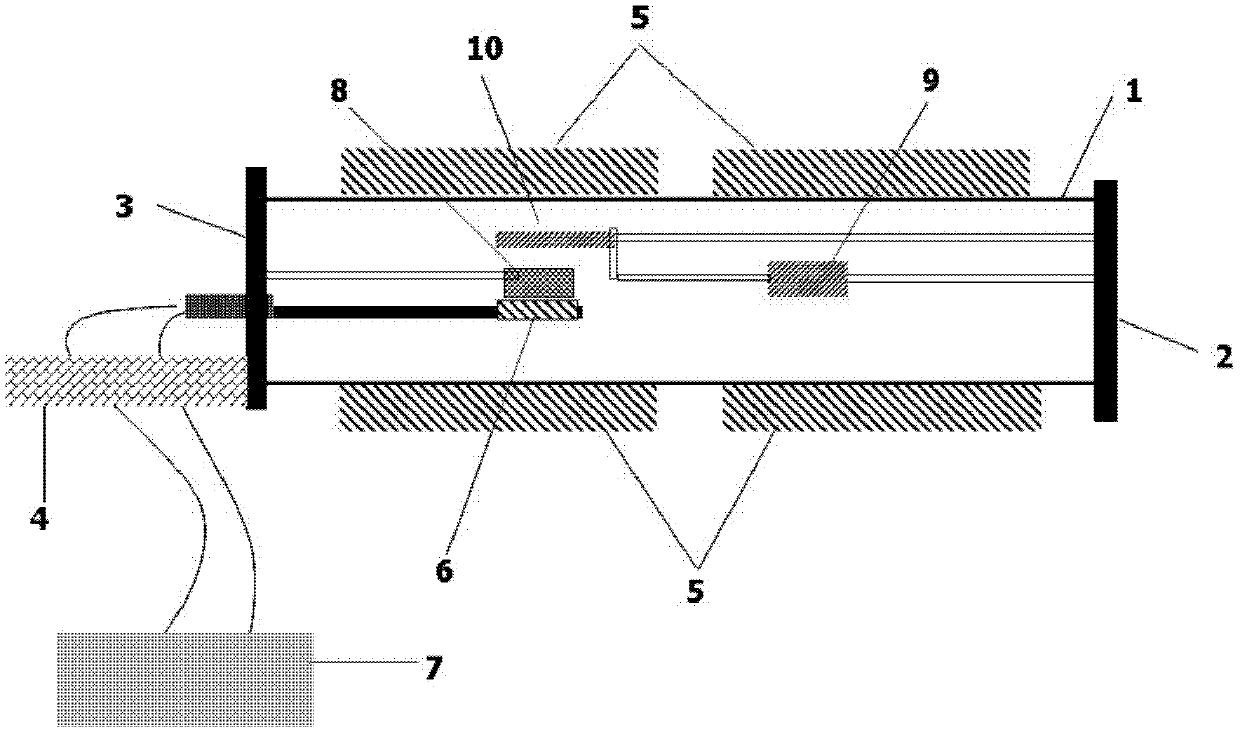

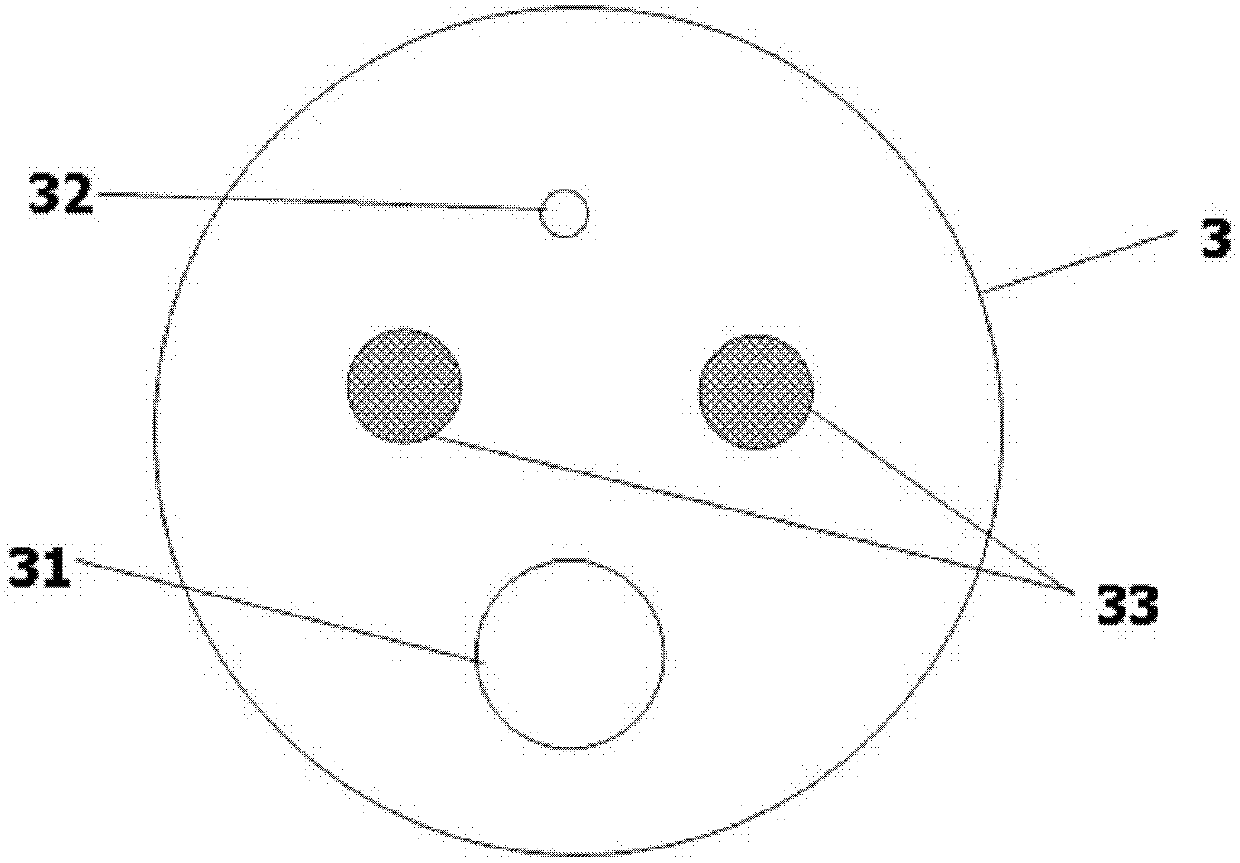

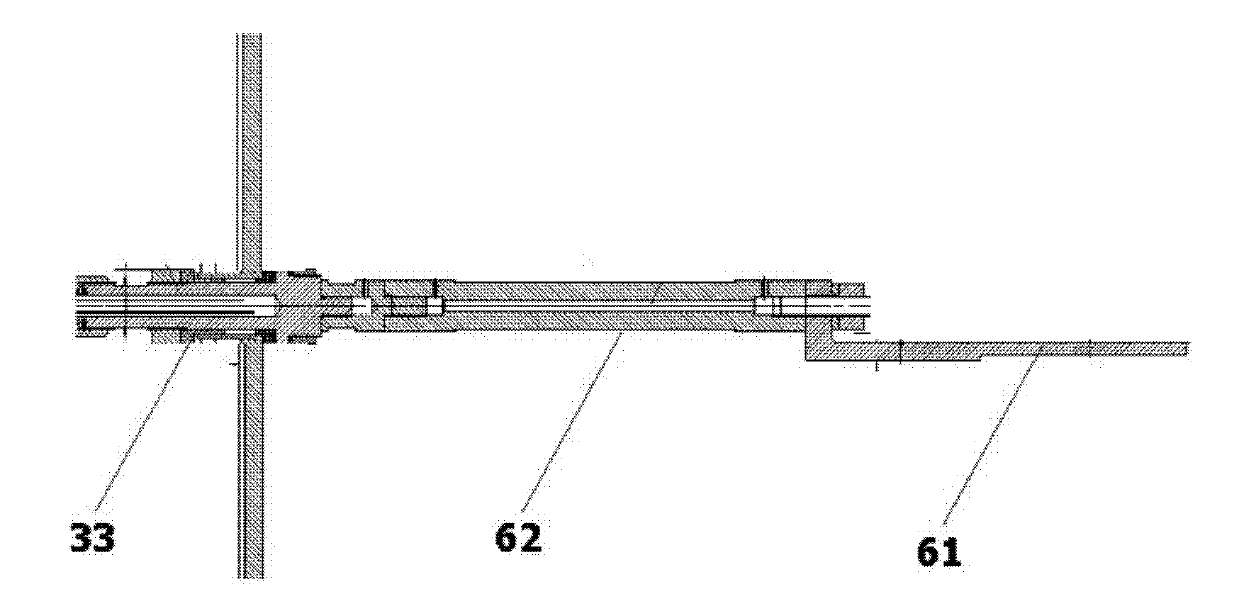

[0018] figure 1 A structural block diagram of a double-heating hydride vapor phase epitaxy growth system in the present invention is shown. Taking horizontal hydride vapor phase epitaxy (HVPE) as an example, such as figure 1 As shown, the system includes: epitaxial growth chamber 1, inlet flange 2, outlet flange 3, slide rail 4, double heating device, power supply and control system 7, sample stage 8, metal reaction source placer 9 and spray device 10. The epitaxial growth chamber 1 is a quartz epitaxial growth chamber 1 placed horizontally or vertically.

[0019] The epitaxial growth chamber 1 is tubular, made of quartz, and can be placed horizontally or vertically. For the epitaxial growth chamber 1 placed horizonta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com