Method for improving photoelectric detector performance by cutting band gap wavelength in lattice matching system

A photodetector and lattice matching technology, which is applied to semiconductor devices, circuits, electrical components, etc., can solve the problems of increasing optical loss and system complexity, not giving full play to device performance, and being unable to use Si detectors, etc., to achieve Reduce the intrinsic carrier concentration, good application prospects, and improve the effect of anti-interference characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

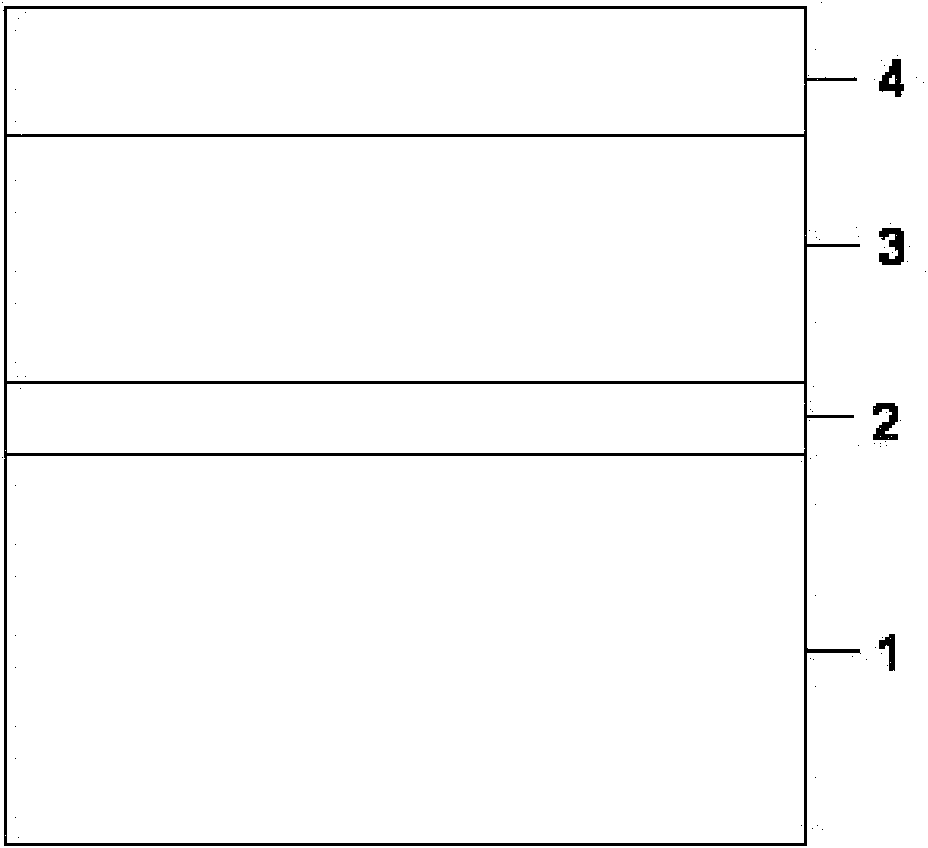

[0022] (1) A lattice-matched photodetector epitaxial structure including a buffer layer, a light absorbing layer and a wide bandgap cap layer was grown on an InP substrate by molecular beam epitaxy (MBE). The InP substrate adopts semi-insulating conductivity type; the buffer layer adopts In with narrow band gap. 0.53 Ga 0.47 As, the thickness is 200 nanometers, the doping and its concentration are determined according to the final requirements of the device; the light absorbing layer is unintentionally doped, and the thickness of the quaternary InAlGaAs set for its bandgap tailoring is 1 micron; The capping layer can be unintentionally doped, and the material is In 0.52 al 0.48 As, with a thickness of 0.5 μm;

[0023] (2) The composition of the quaternary InAlGaAs light-absorbing layer and the tailoring of the band gap are determined according to the long-wave cut-off wavelength requirements of the desired device. In the case of lattice matching with the InP substrate, the...

Embodiment 2

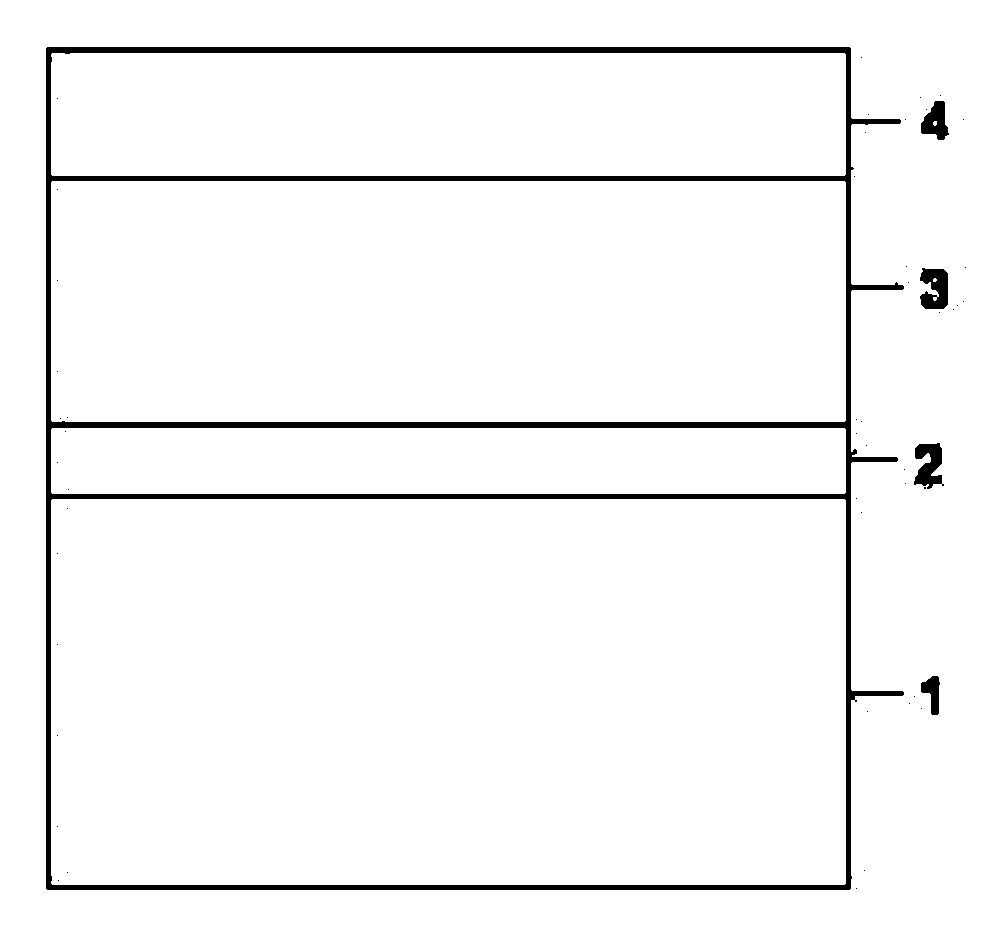

[0026] (1) A lattice-matched photodetector epitaxial structure including a buffer layer, a light absorbing layer and a wide bandgap cap layer was grown on an InP substrate by metal-organic vapor phase epitaxy (MOVPE). The InP substrate adopts N-type highly doped conductivity type; the buffer layer adopts InP material to meet the requirements of back light input, the thickness is 2000 nanometers, and the doping and its concentration can also be determined according to the final requirements of the device; the light absorbing layer is low-doped n-type, using quaternary InGaAsP set for its bandgap tailoring, with a thickness of 3 microns; the wide bandgap cap layer is a highly doped p-type material, InP, with a thickness of 1 micron;

[0027] (2) The composition of the quaternary InGaAsP light-absorbing layer and the tailoring of the band gap are determined according to the long-wave cut-off wavelength requirements of the desired device. In the case of lattice matching with the I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com