Hydride vapor phase epitaxy device

A technology of hydride gas phase and gas inlet device, which is applied in the direction of chemical reactive gas, gaseous chemical plating, chemical instruments and methods, etc., can solve the problem that the uniformity of large-scale GaN substrate materials cannot be guaranteed, and it is difficult to carry out large-scale production. Production and other problems, to achieve the effect of simple structure and improved crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

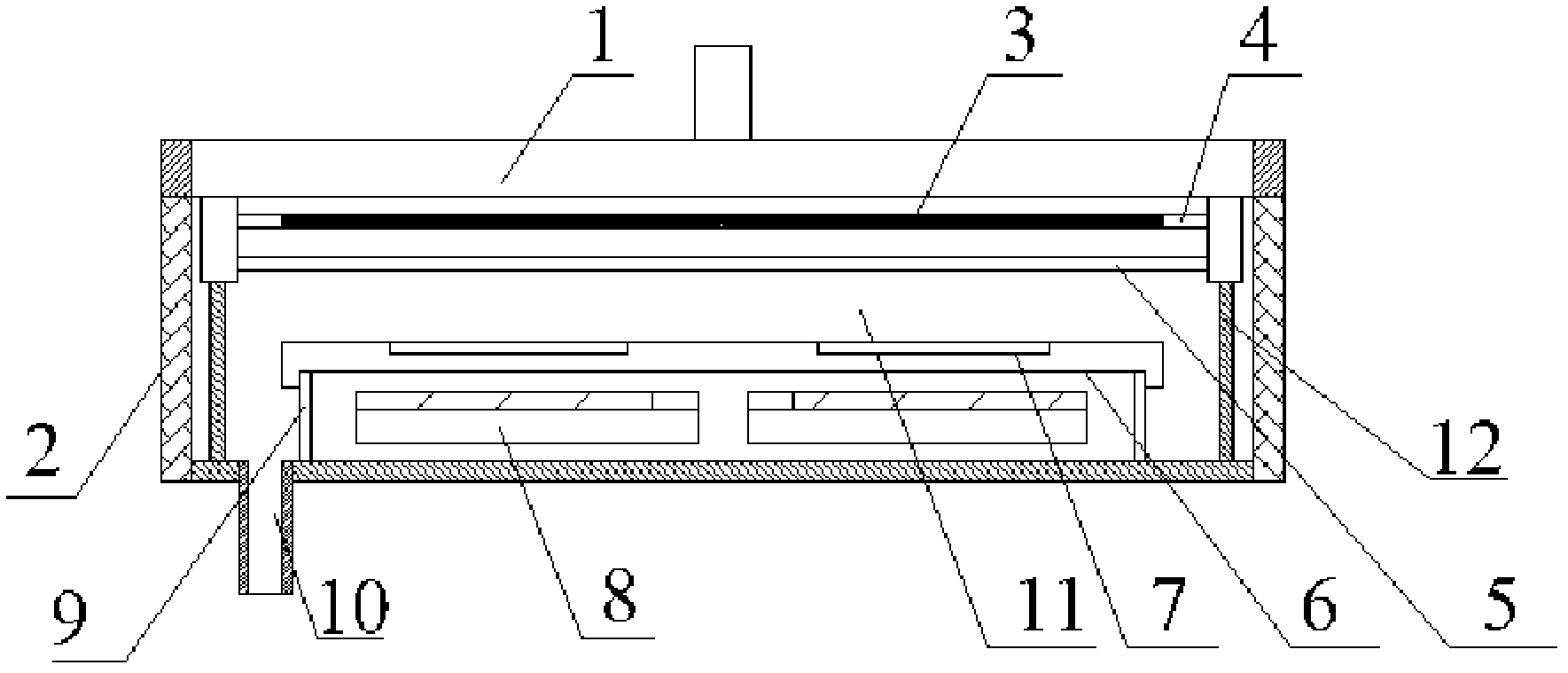

[0016] Such as figure 1 Shown is a schematic diagram of the design of the device of the present invention.

[0017] The upper part of the vapor phase epitaxy reaction chamber is equipped with an air inlet device 1, which can be fed with different types, different flow rates or flow rates, and different concentrations of reaction gases or carrier gases such as hydrogen and nitrogen according to the requirements of the epitaxy process; a quartz boat is installed under the air inlet device 1 4. The quartz boat 4 is made of a quartz tube or a ceramic tube with openings. The metal source 3 is placed in the quartz boat 4, and the hydrogen chloride reaction gas introduced by the air inlet device 1 reacts with it to form metal chlorides; the lower part of the reaction chamber A loading tray 6 is provided to place the substrate 7; a heating device 8 is provided below the loading tray 6, and a heating device 5 is arranged between the loading tray 6 and the quartz boat 4 above the loadin...

Embodiment 2

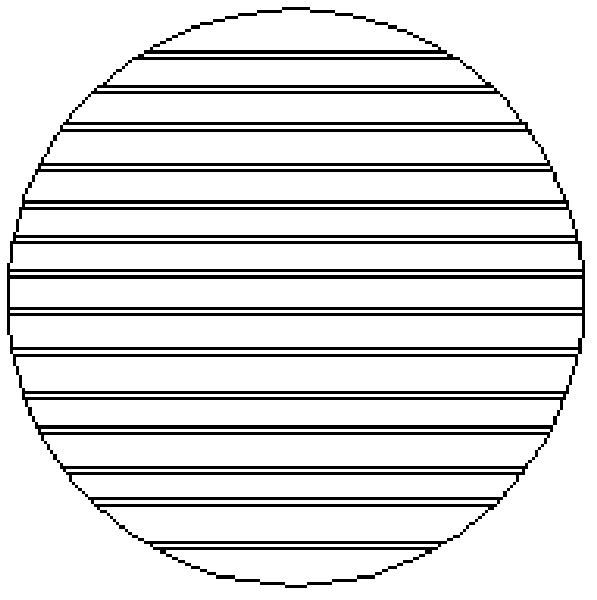

[0020] This embodiment is the same as the first embodiment, the difference is that the quartz boat 4 is a straight tube or an annular tube of a quartz tube or a ceramic tube, and a straight tube structure in which multiple tubes are arranged at intervals in a plane. Such as figure 2 So not.

Embodiment 3

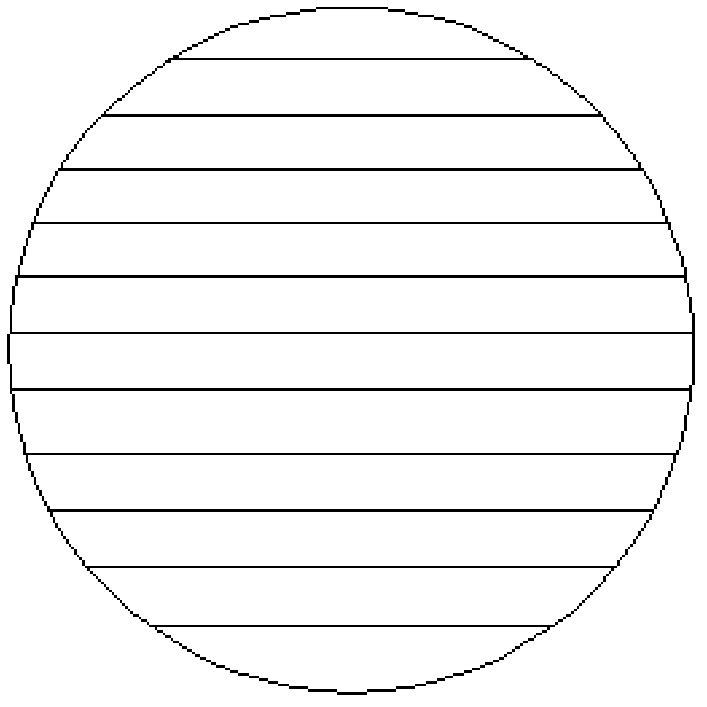

[0022] This embodiment is the same as the first embodiment, the difference is that the heating elements of the heating device 5 above the slide tray 6 are arranged at intervals in a plane. Such as image 3 shown

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com