Method for changing polar of gallium nitride epitaxial layer grown by hydride vapour phase epitaxy method

A hydride vapor phase and epitaxial growth technology, applied in coatings, electrical components, gaseous chemical plating, etc., can solve problems such as reducing the dislocation density of GaN thin films, and achieve the effects of low cost, simple and easy method, and improved performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

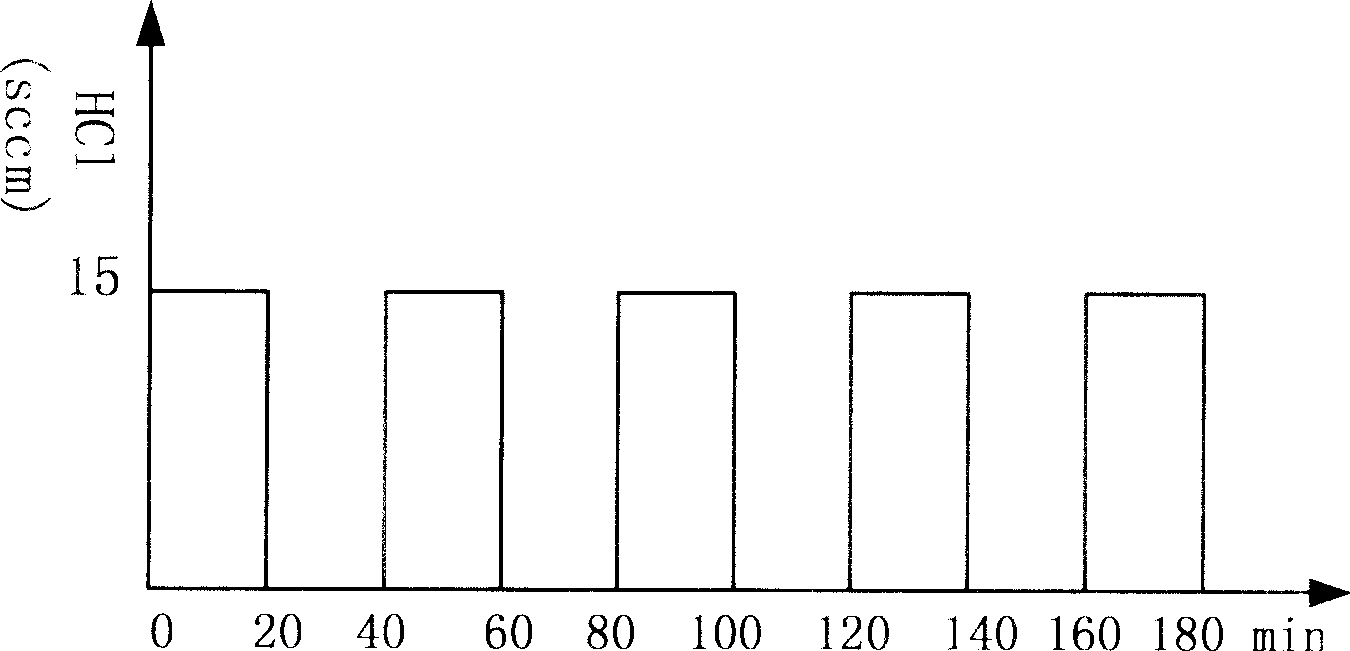

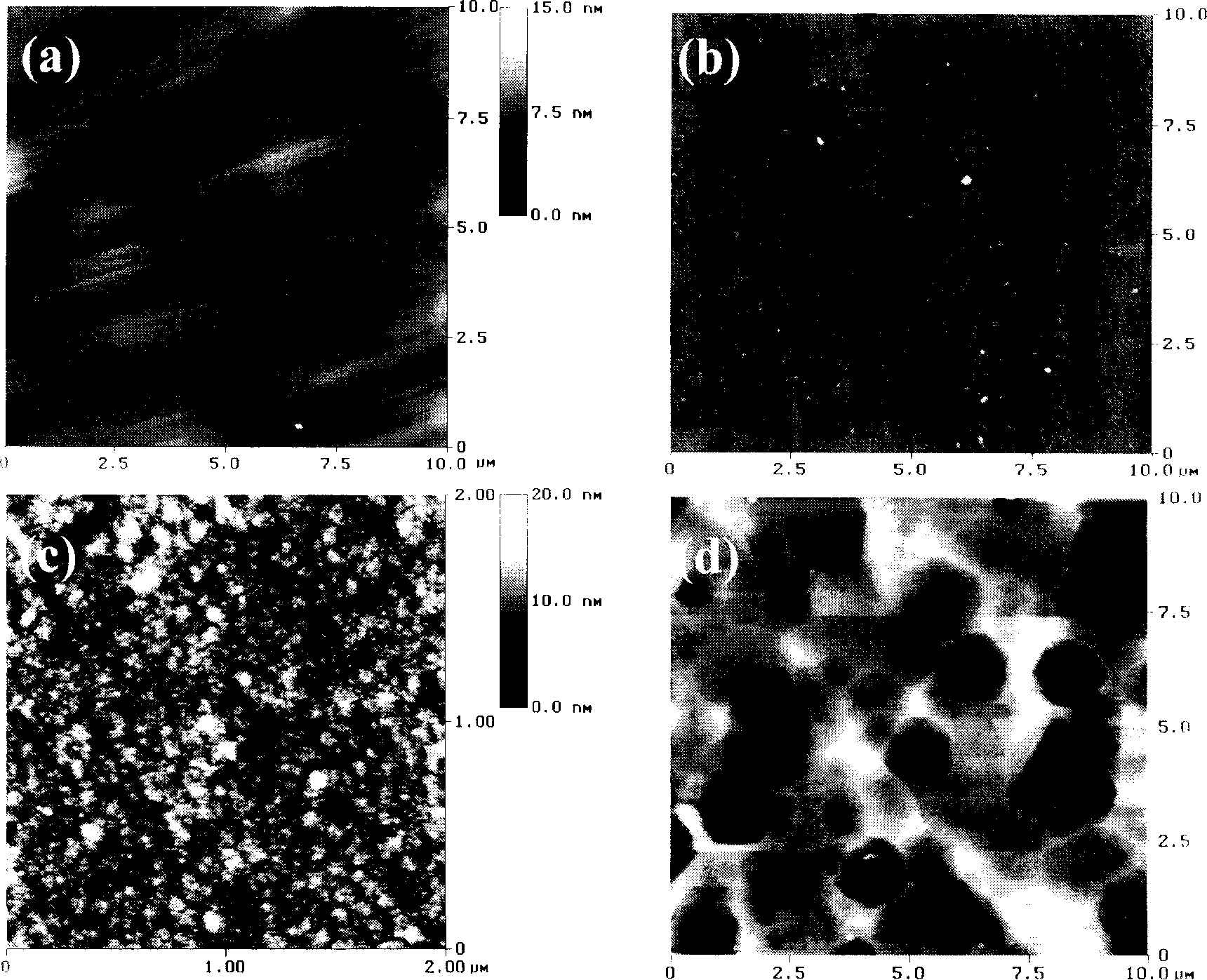

Embodiment 1

[0016] The method provided by the invention is used in HVPE to change the polarity of GaN material growth, and the growth of GaN adopts Al 2 o 3 As a substrate, first pass NH at high temperature 3 to Al 2 o 3 The substrate was nitrided for 7min, NH 3 The flow rate is 500 sccm, so that the thin AlN island structure is formed on the surface to facilitate the nucleation of GaN. Then grow with HCl gas, at this time the surface of the grown GaN film shows N polarity. After growing for 30min, the thickness of the GaN film was 10μm, then the HCl gas was turned off, and the reaction gas NH 3 and H 2 or N 2 The gas flow rate of the carrier gas remains constant, and the process lasts for 20 minutes. Then continue to open the HCl gas for growth for 20 minutes, then turn off the HCl gas for 20 minutes, and repeat this 4 times. The obtained GaN material will change from N polarity to Ga polarity with smooth surface and stable chemical properties, and its crystal quality will also b...

Embodiment 2

[0020] GaN is grown on a Si substrate, and the HCl growth is interrupted by the method shown in Example 1. The number of interruptions is 8 times, and each time is 10 minutes. The thickness of the grown N-polar GaN film is 20 μm, and the interrupted growth temperature is 950°C. The surface dislocation density of Ga polar GaN material is 1×10 7 / cm 2 . All the other are similar with embodiment 1.

Embodiment 3

[0022] GaAs substrates are used to grow N-polar GaN materials by molecular beam epitaxy growth method. The interrupted growth temperature is 900-1100°C, the number of interrupts is 2-10 times, and the duration of each time is 1-60min. NH 3 The reaction gas flow rate is 500-700sccm, and the carrier gas is N 2 and H 2 of mixed gas. The resulting GaN material has a surface dislocation density of 1×107 / cm 2 , the surface roughness is only 0.527nm (similar to Example 1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com