Reactor and method for vapor phase epitaxy of nitride semiconductor material

A nitride semiconductor and vapor phase epitaxy technology, applied in the field of semiconductors, can solve problems such as complicated rotating mechanisms, and achieve the effects of simplifying devices, eliminating adverse effects and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

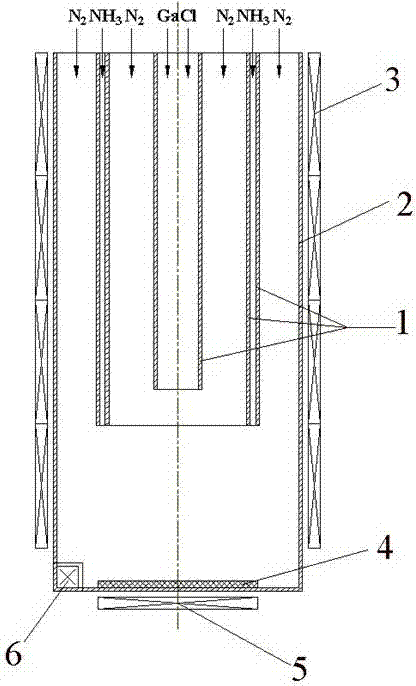

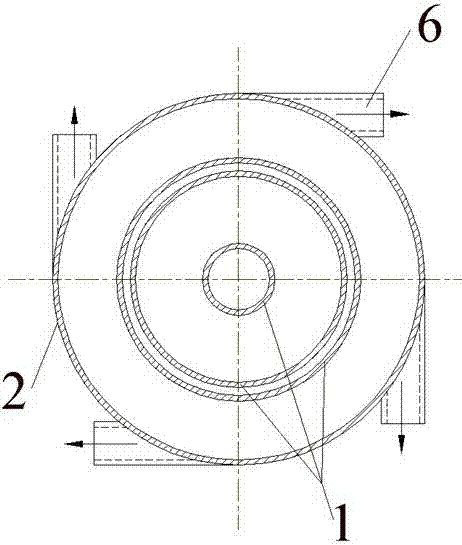

[0018] Embodiment 1: as figure 1 As shown, in the suspended vertical HVPE system, the precursor gas and barrier gas are injected from the concentric ring nozzle 1 at the top of the reactor, and the length of the inner circular tube in the precursor channel is slightly shorter than the length of the outer circular tube; the periphery of the nozzle 1 is a shaft A symmetrical cylindrical reactor cavity 2; the outer wall of the cavity is wrapped with a resistance wire heater 3 and covers the entire cavity in the axial direction; a graphite boat disc 4 is placed directly under the nozzle 1, and the upper surface of the graphite boat disc 4 is set There are a plurality of pockets in which substrate wafers are loaded. The temperature of the graphite boat disc 4 and the substrate is maintained at 1070° C. by heating the resistance wire 5 alone or by infrared light irradiation. like figure 2 As shown, the reacted mixed gas in the reactor is discharged through the outlet channel 6 ar...

Embodiment 2

[0019] Embodiment 2: as Figure 3A , 3B As shown, the reactor is further improved on the basis of Example 1. In order to further expand the effective area of the growable material, a concentric ring buffer zone 7 is set between the mixed gas outlet channel 6 and the inner wall of the cavity 2. The buffer The height of the belt 7 is consistent with the height of each gas outlet channel 6. This design expands the effective area of the substrate where materials can grow, and at the same time weakens the adverse effect of the violent flow of fluid at each outlet on the uniform growth of nitride materials on the substrate.

Embodiment 3

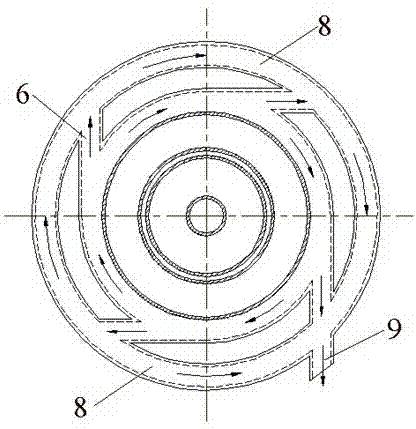

[0020] Embodiment 3: as Figure 4 As shown, in combination with the advantages of Embodiments 1 and 2, the reactor has been further improved, and a concentric ring collecting channel 8 with an axisymmetric cavity is arranged on the periphery of the gas outlet channel 6 after the reaction of the reactor. The cross-section of the collecting channel 8 is rectangular or circular, and each reaction gas outlet channel 6 is connected with the collecting channel 8, and the collecting channel 8 is only designed with one outlet 9, so as to collect the gases discharged from each outlet channel for centralized treatment.

[0021] The reactor for vapor phase epitaxy of nitride semiconductor materials proposed by the present invention replaces the graphite boat rotating device, auxiliary components and driving motors in the existing HVPE growth system by adopting a structural design of tangential discharge for the gas outlet channel after reaction, not only It greatly simplifies the device,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com