Vapor-phase epitaxy deposition apparatus realizing nitride crystal homoepitaxy

A nitride crystal, vapor phase epitaxy technology, applied in the direction of crystal growth, chemical reactive gas, single crystal growth, etc., can solve the problems of inability to meet commercialization, difficult to achieve large-scale GaN single crystal, etc., to improve quality and growth. Speed, performance-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

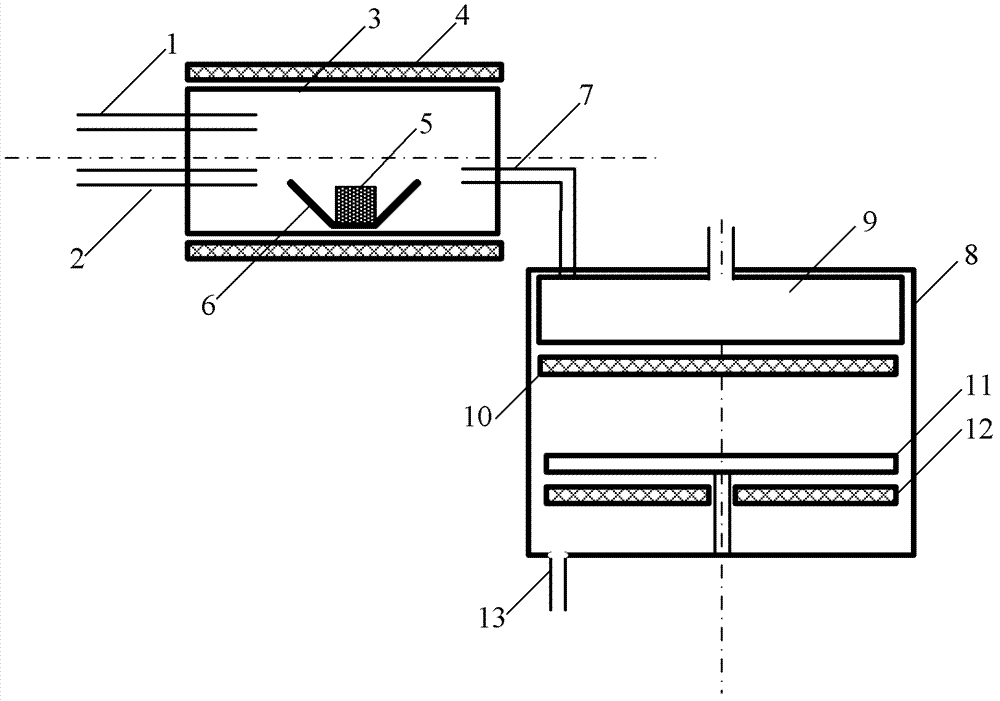

[0018] Such as figure 1 Shown is a schematic diagram of the design of the device of the present invention.

[0019] The outside of the metal chloride supply chamber 3 is provided with a heating device 4 and a ventilation pipe for introducing hydrogen chloride reaction gas or hydrogen or nitrogen as a carrier gas, and the generated metal chloride reaction gas is carried by the carrier gas into the metal organic compound vapor phase epitaxy reaction chamber; A quartz boat 6 is arranged inside the chloride supply chamber 3, and a reaction gas inlet device 9 is arranged on the upper part of the metal-organic compound vapor phase epitaxy reaction chamber 8 (abbreviation: vapor phase epitaxy reaction chamber), which can make the organic matter of gallium, indium, magnesium, and aluminum Reaction gas, group V source reaction gas such as ammonia and silane and other dopant source gases enter the reaction chamber; the lower part of the vapor phase epitaxy reaction chamber 8 is provided...

Embodiment 2

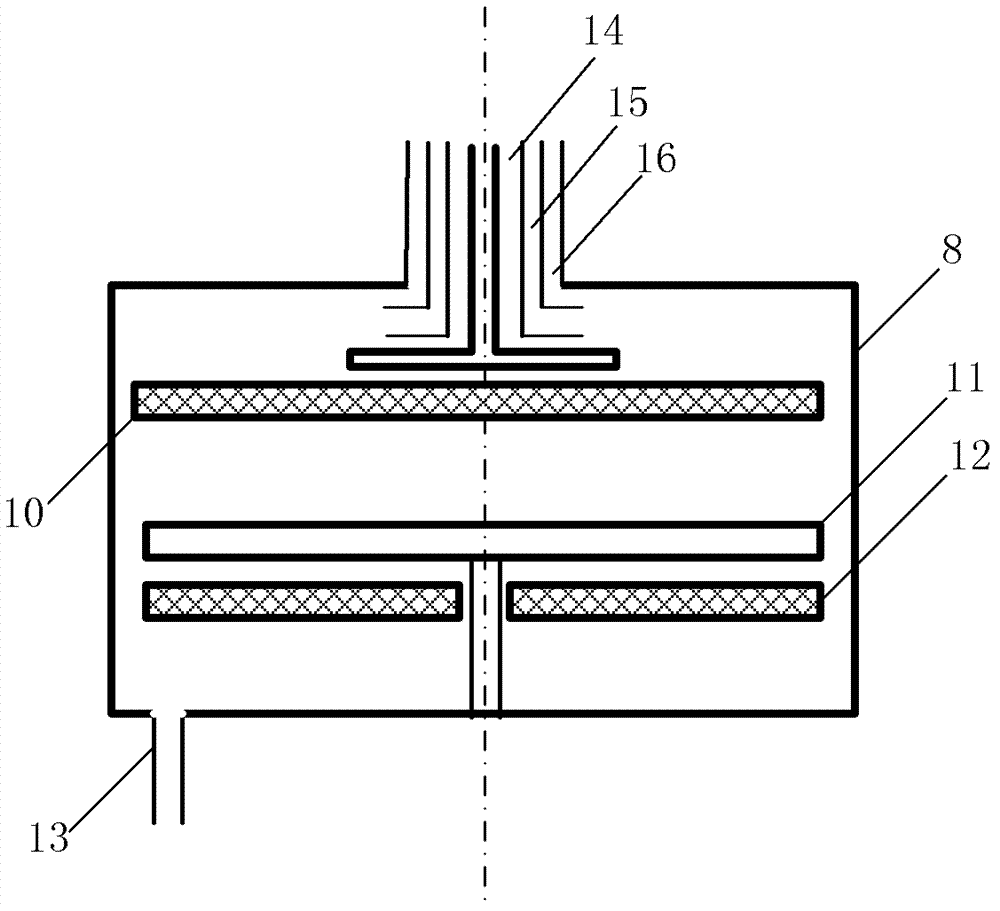

[0022] This embodiment is the same as the above-mentioned implementation one, the difference is that the reactant gas inlet device is as follows figure 2 As shown in the central three-laminar nozzle inlet structure, when the gallium nitride thick film is growing, the gallium chloride gas and the carrier gas enter the vapor phase epitaxy reaction chamber 8 through the inlet pipe 15, and the mixed gas of ammonia gas and the carrier gas It enters the reaction chamber 8 through the gas inlet pipe 14 and the gas inlet pipe 16; when growing the gallium nitride thin film, the metal gallium organic compound carried by the carrier gas is fed through the gas inlet pipe 15.

Embodiment 3

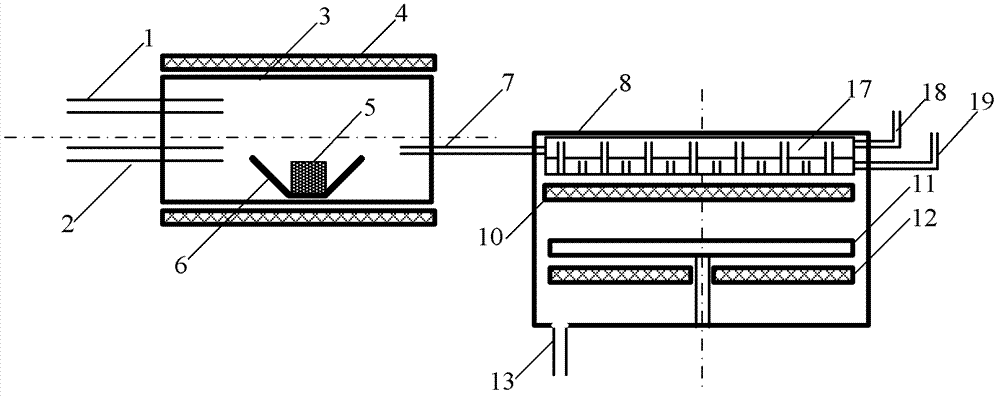

[0024] This embodiment is the same as Embodiment 1, the difference is that the reaction gas inlet device is such as image 3 In the spray structure shown, when the gallium nitride thick film is grown, the gallium chloride gas and the carrier gas enter the gas buffer chamber of the spray 17 through the intake pipe 7, and the mixed gas of ammonia gas and the carrier gas flows from the intake gas The pipeline 19 enters the gas buffer chamber of the spray 17, and the two reaction gases flow out from the spray hole and then mix and react; Gas-carried gallium metal organic compounds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com