Square spray nozzle structure for vapor phase epitaxy of material

A technology of vapor phase epitaxy and nozzle, which is applied in the field of square nozzle structure for material vapor phase epitaxy, which can solve the problems of low production efficiency, small coverage area, uneven mixing of precursors, etc., and achieve the effect of improving production efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

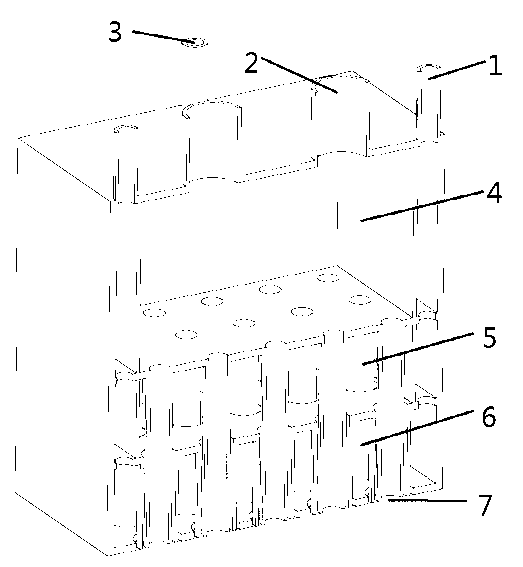

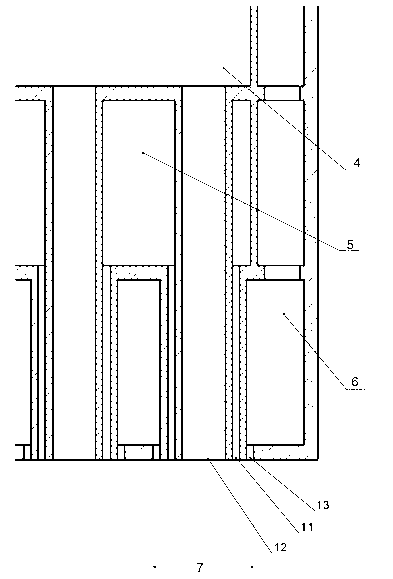

Embodiment 1

[0024] Reactions involving chemical vapor deposition (CVD) or hydride vapor phase epitaxy (HVPE) require high temperature conditions. Therefore, the material of the nozzle structure needs to be selected with high strength, no chemical reaction with the reaction gas, and a material with a low thermal expansion coefficient.

[0025] Quartz material has a low coefficient of thermal expansion, high strength, and does not react with various reactive gases, so quartz is used to make the nozzle.

[0026] After hydrogen chloride passes through the gallium source, it forms a mixture of gallium chloride, and enters the first isolation area of the nozzle through the pipe, diffuses evenly in the nozzle, and then discharges through the central pipe below.

[0027] Ammonia gas enters the sprinkler head through the intake pipe, spreads evenly in the ammonia gas area, and then is discharged through the pipe below.

[0028] Nitrogen enters the spray head through the intake pipe, spreads eve...

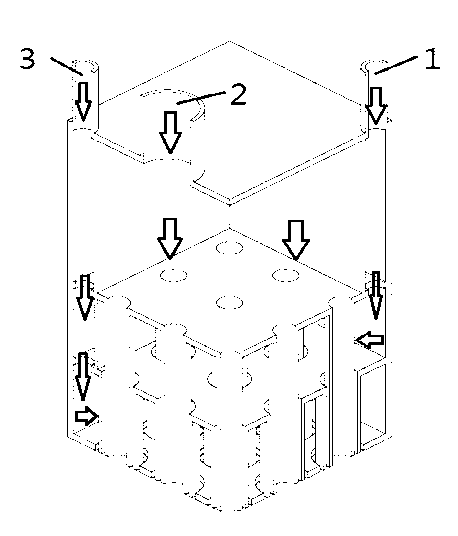

Embodiment 2

[0032]Reactions involving chemical vapor deposition (CVD) or hydride vapor phase epitaxy (HVPE) require high temperature conditions. Therefore, the material of the nozzle structure needs to be selected with high strength, no chemical reaction with the reaction gas, and a material with a low thermal expansion coefficient.

[0033] Quartz material has a low coefficient of thermal expansion, high strength, and does not react with various reactive gases, so quartz is used to make the nozzle.

[0034] By using multiple quartz shower heads in combination, a larger reaction area can be formed in the reaction chamber, which is beneficial to the growth of large-sized substrates or a large number of substrates.

[0035] After hydrogen chloride passes through the gallium source, it forms a mixture of gallium chloride, and enters the first isolation area of the nozzle through the pipe, diffuses evenly in the nozzle, and then discharges through the central pipe below.

[0036] Ammonia g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com