Method for manufacturing gallium nitride substrate using the hydride vapor phase epitaxy

a technology of nitride and hydride, which is applied in the direction of basic electric elements, electrical apparatus, semiconductor devices, etc., can solve the problems of reducing the crystallinity of nitride semiconductor substrates, cracks, and reducing the electrical characteristics of devices, so as to reduce the flow rate ratio of ammonia gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

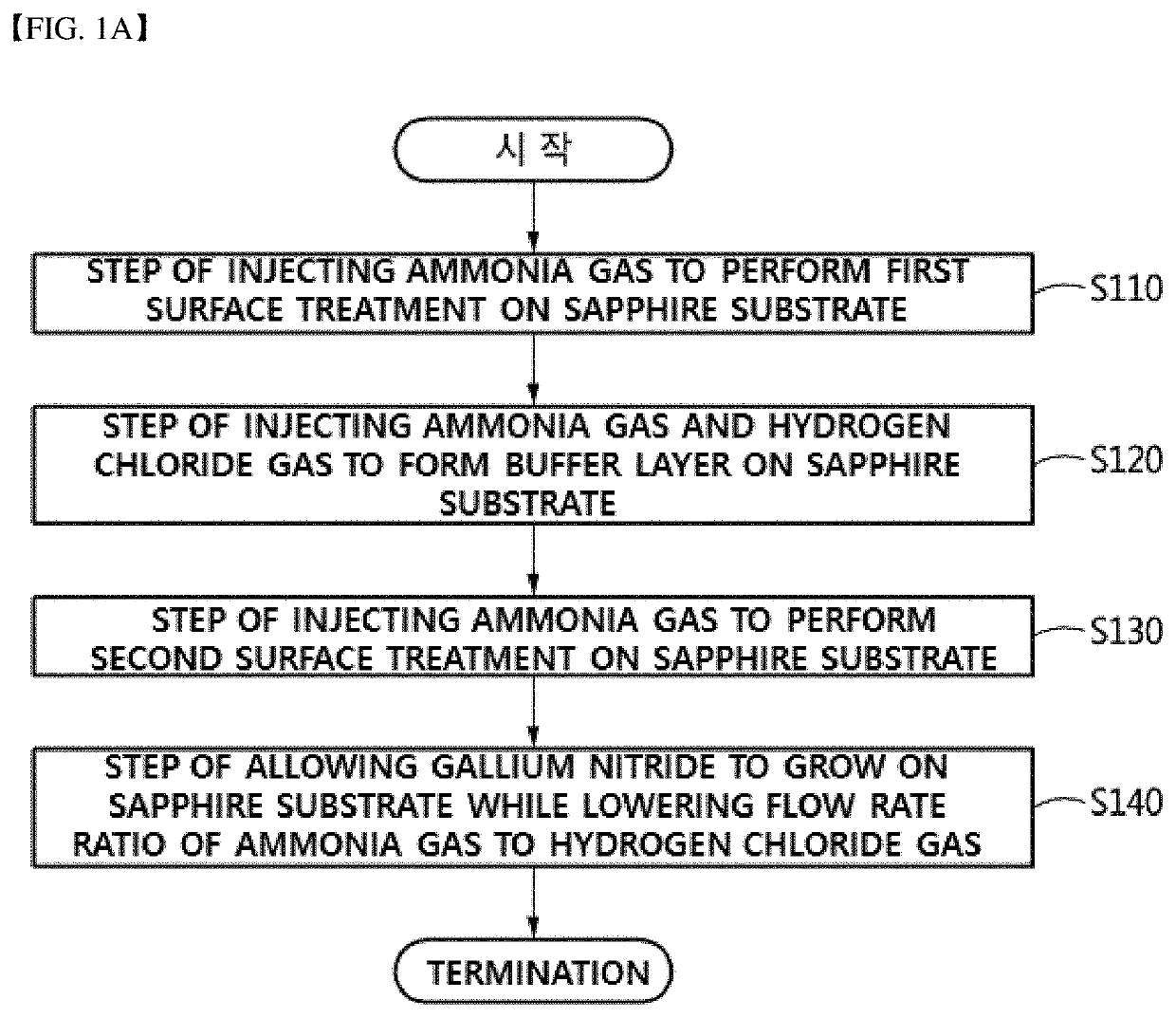

[0122]After a sapphire substrate was inserted into a hydride vapor phase growth reactor, the first surface treatment was performed at a temperature of 950° C. while ammonia gas was supplied, an aluminum nitride buffer layer was formed while ammonia gas and hydrogen chloride gas were supplied, and the second surface treatment was performed while ammonia gas was supplied again.

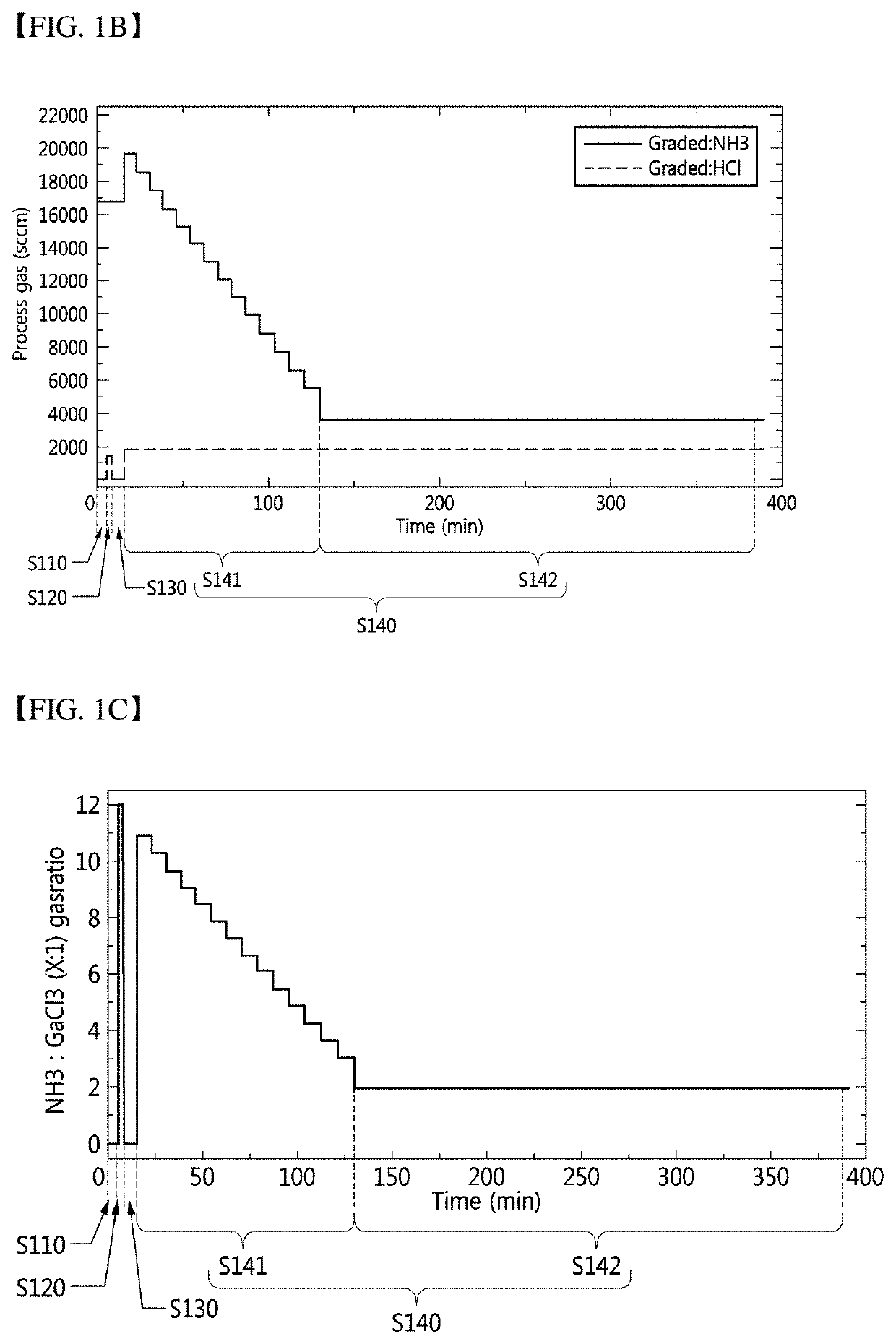

[0123]Next, gallium was placed in a gallium container included in the hydride vapor phase growth reactor, and hydrogen chloride gas was supplied while maintaining temperature at 850° C. to generate gallium chloride gas. Through another injection port, ammonia gas was supplied to the container set to a temperature of 950° C. while reducing the flow rate of ammonia gas stepwise (i.e., lowering the flow rate ratio (x:1) of ammonia gas to hydrogen chloride gas stepwise), so that gallium nitride having a thickness of about 300 μm was allowed to grow on a single crystal substrate.

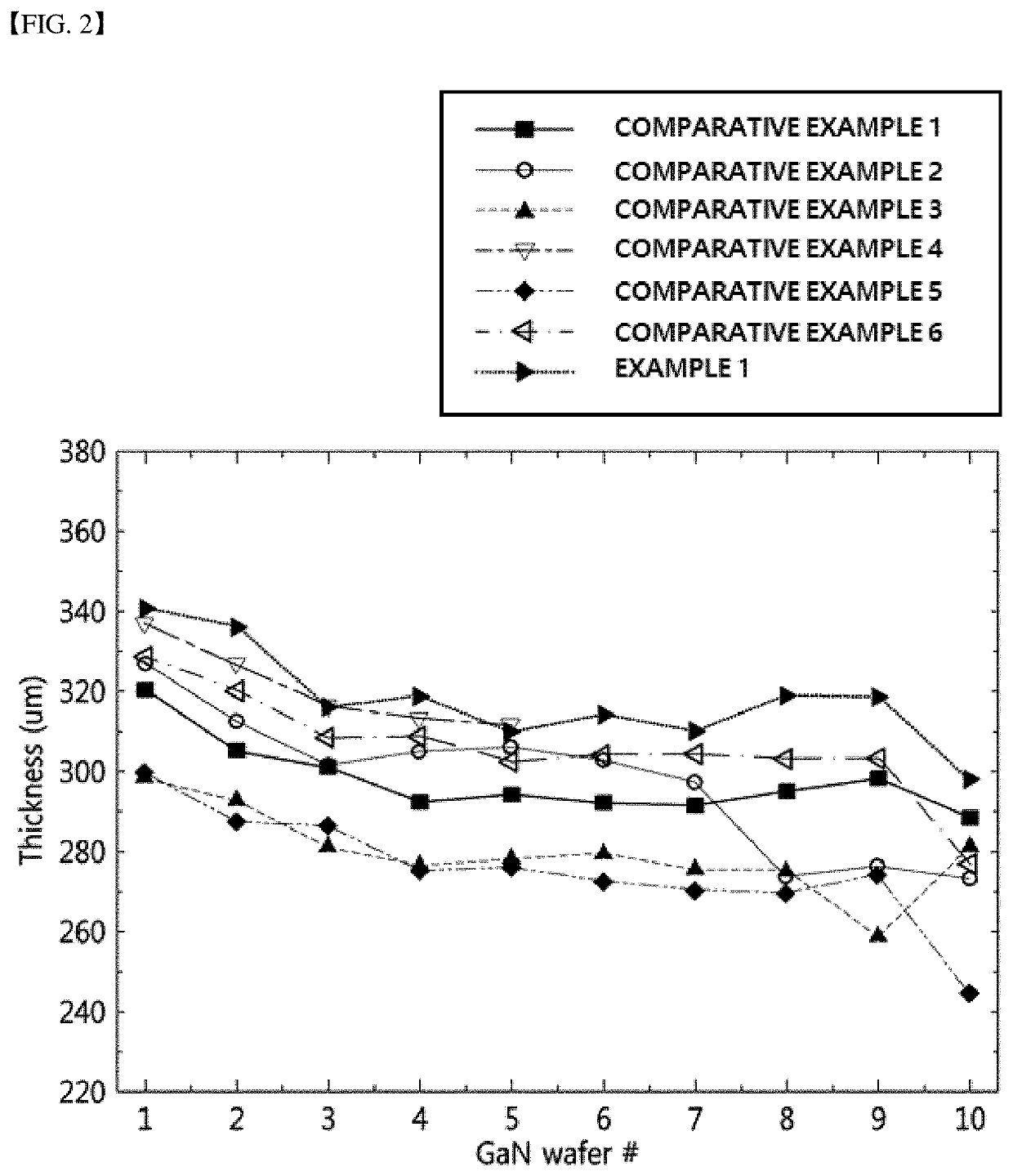

[0124]In addition, 10 gallium nitride ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com