Temperature modulating electro-chemical electrode and its heating method

A heating method and electrochemical technology, applied in the field of electrochemistry, can solve the problem of not being able to prevent the flow of capacitive current, and achieve the effects of simplifying the structure of the device, wide application range, and good application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

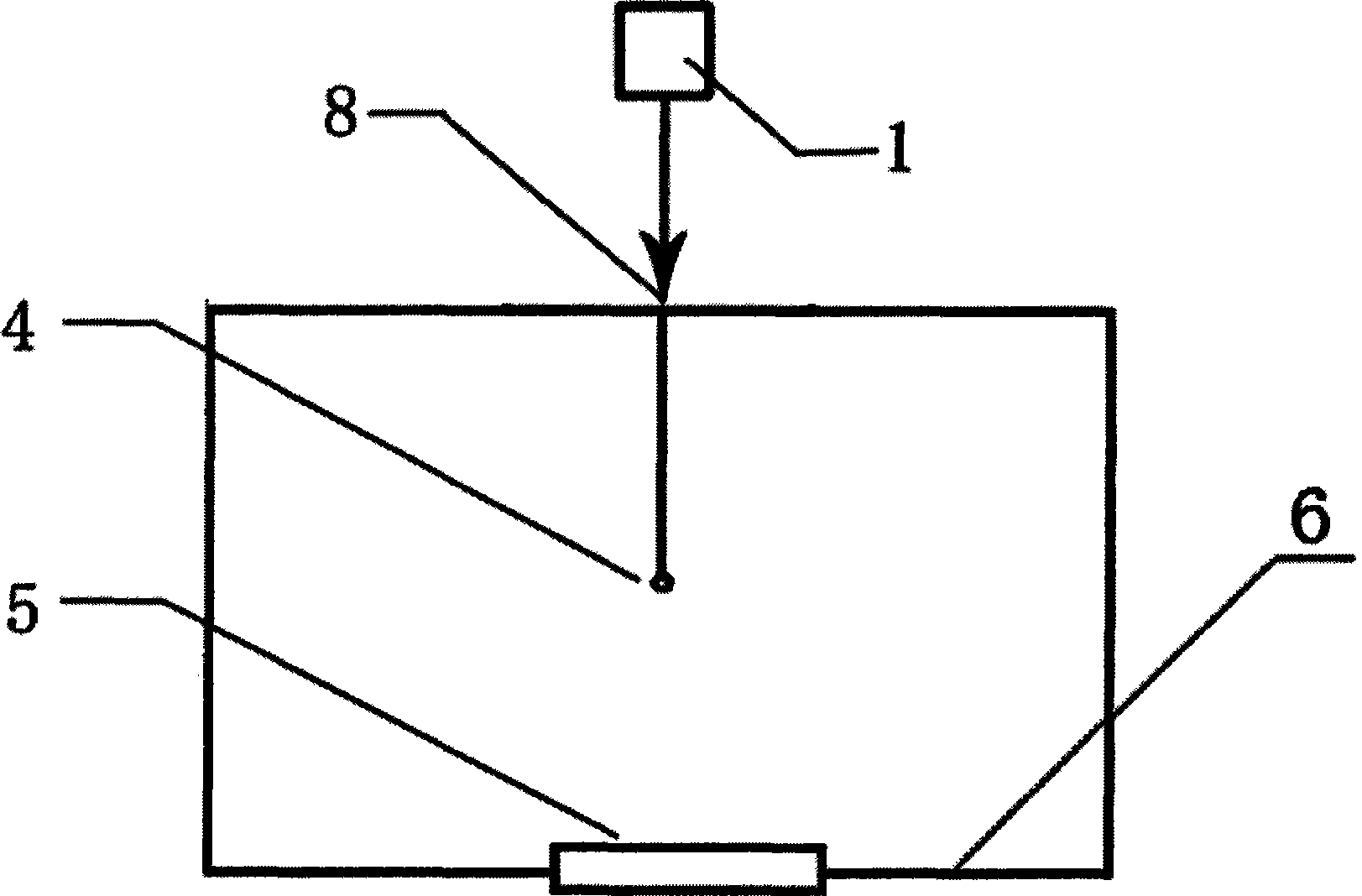

Embodiment 1

[0030]A carbon column thermoelectrode with a diameter of 104 μm was fabricated into a temperature-modulated electrochemical electrode and used as a working electrode. The electrode potential method was used to characterize the relationship between the heating current and the electrode temperature. The reference electrode is a saturated calomel electrode (SCE), the counter electrode is a platinum electrode, and the working electrode is heated by a 100KHz sine wave alternating current. The temperature modulation voltage is investigated by cyclic voltammetry in an electrochemical analyzer CHI440 (Shanghai Chenhua Instrument Co., Ltd.) Chemical electrode at 5mM K 3 Fe(CN) 6 The response to potassium ferricyanide in the +0.1M KCl system, the results of the investigation are as follows Figure 5 Shown, the experimental results and the response of the symmetrical structure design thermode to potassium ferricyanide ( Figure 4 ) For comparison, it can be seen from the figure that as heatin...

Embodiment 2

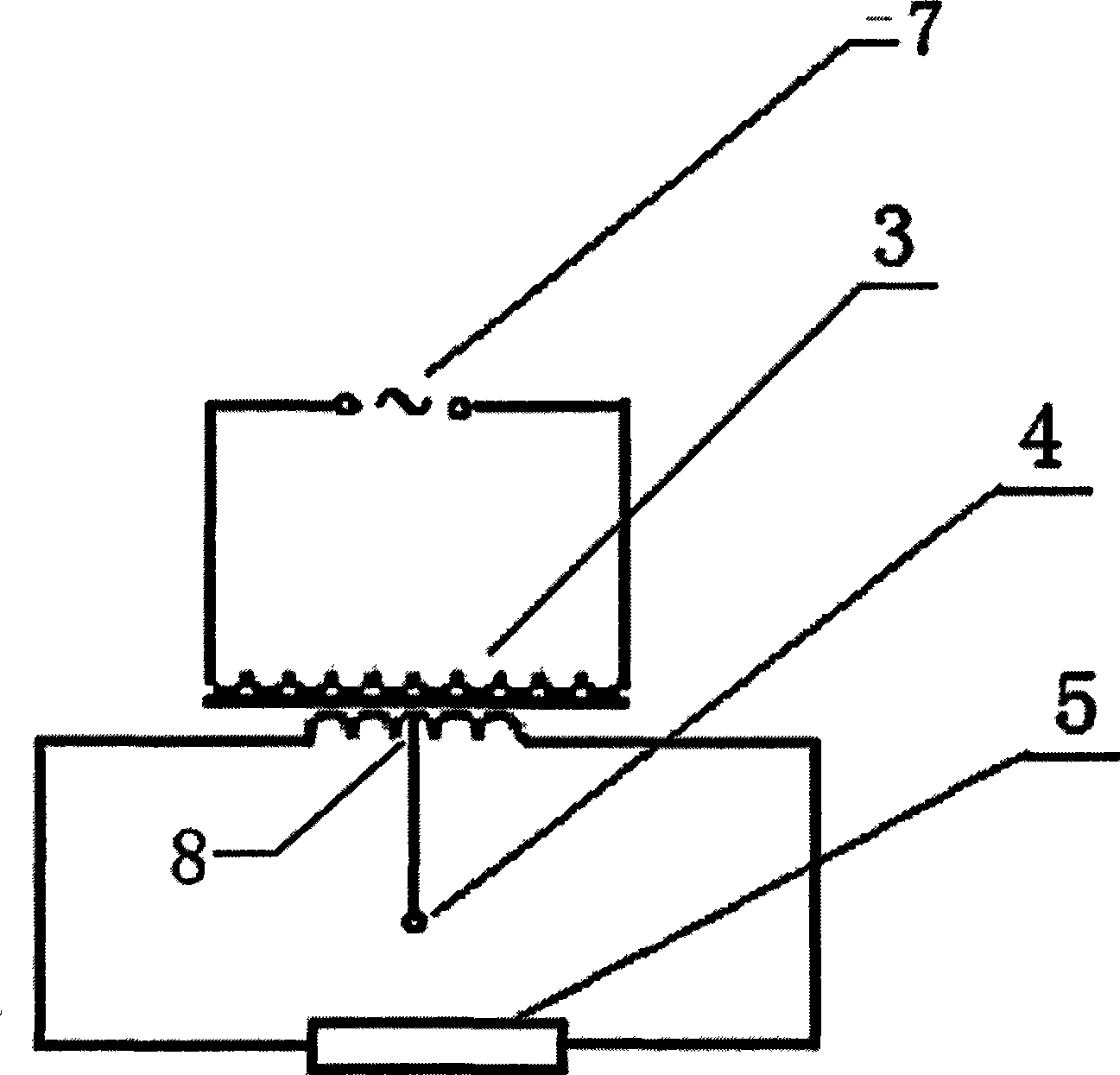

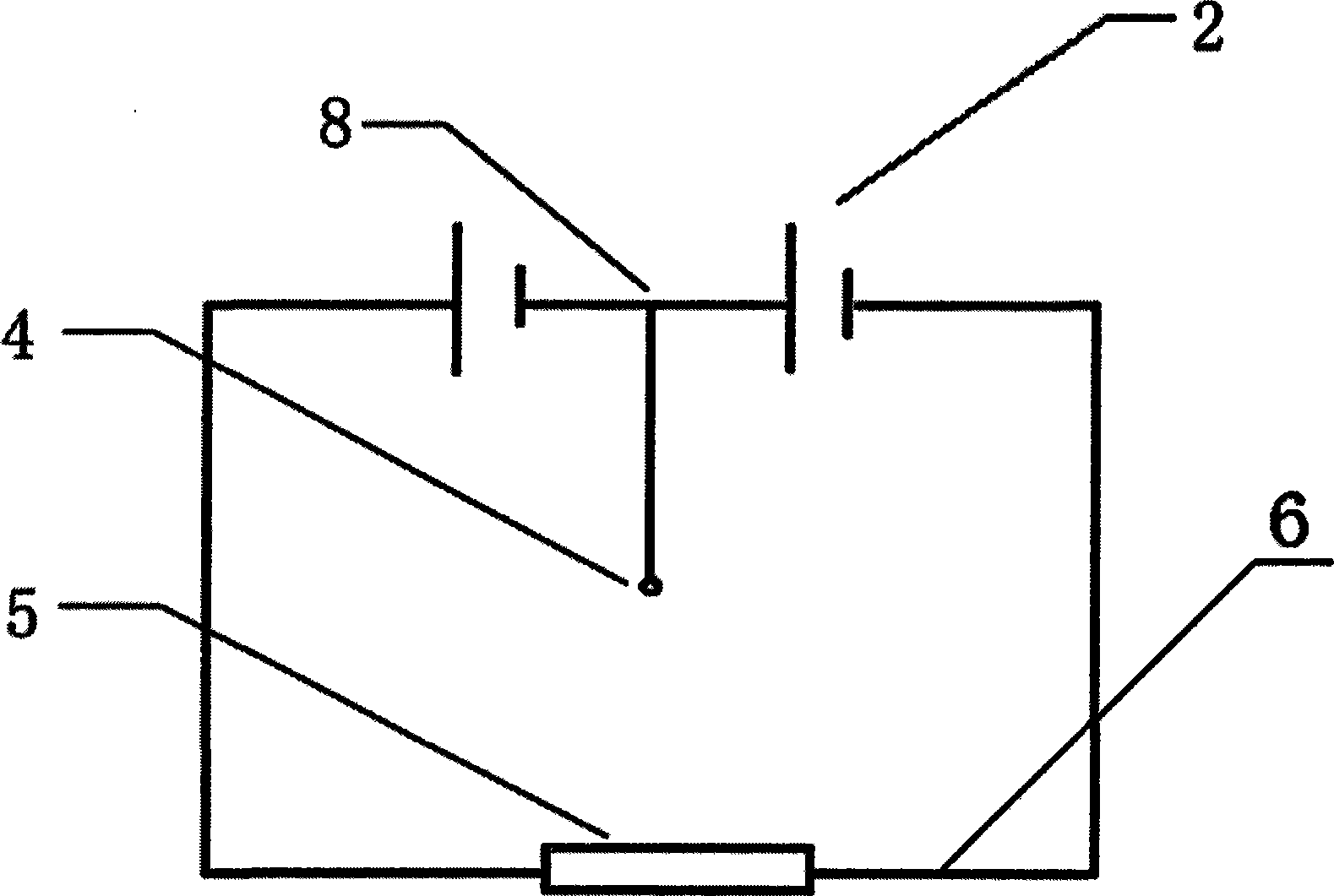

[0032] A carbon column thermoelectrode with a diameter of 150 μm was fabricated into a temperature-modulated electrochemical electrode and used as a working electrode. The electrode potential method was used to characterize the relationship between the heating current and the electrode temperature. The reference electrode is a saturated calomel electrode (SCE), the counter electrode is a platinum electrode, and the working electrode is heated by two DC power supplies connected in series. The heating method is as follows: image 3 As shown, the measurement connector is connected to the middle position between the two DC power supplies. The electrochemical analyzer CHI440 (Shanghai Chenhua Instrument Co., Ltd.) uses cyclic voltammetry to investigate the temperature-modulated electrochemical electrode at 5mM K 3 Fe(CN) 6 The response to potassium ferricyanide in +0.1M KCl system. As the applied heating current increases, the surface temperature of the temperature-modulated electroche...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com