Preparation method of InGaN thin film

A thin film and substrate technology, applied in the field of InGaN thin film preparation, can solve problems such as surface roughness and phase separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for preparing an InGaN film includes the following steps:

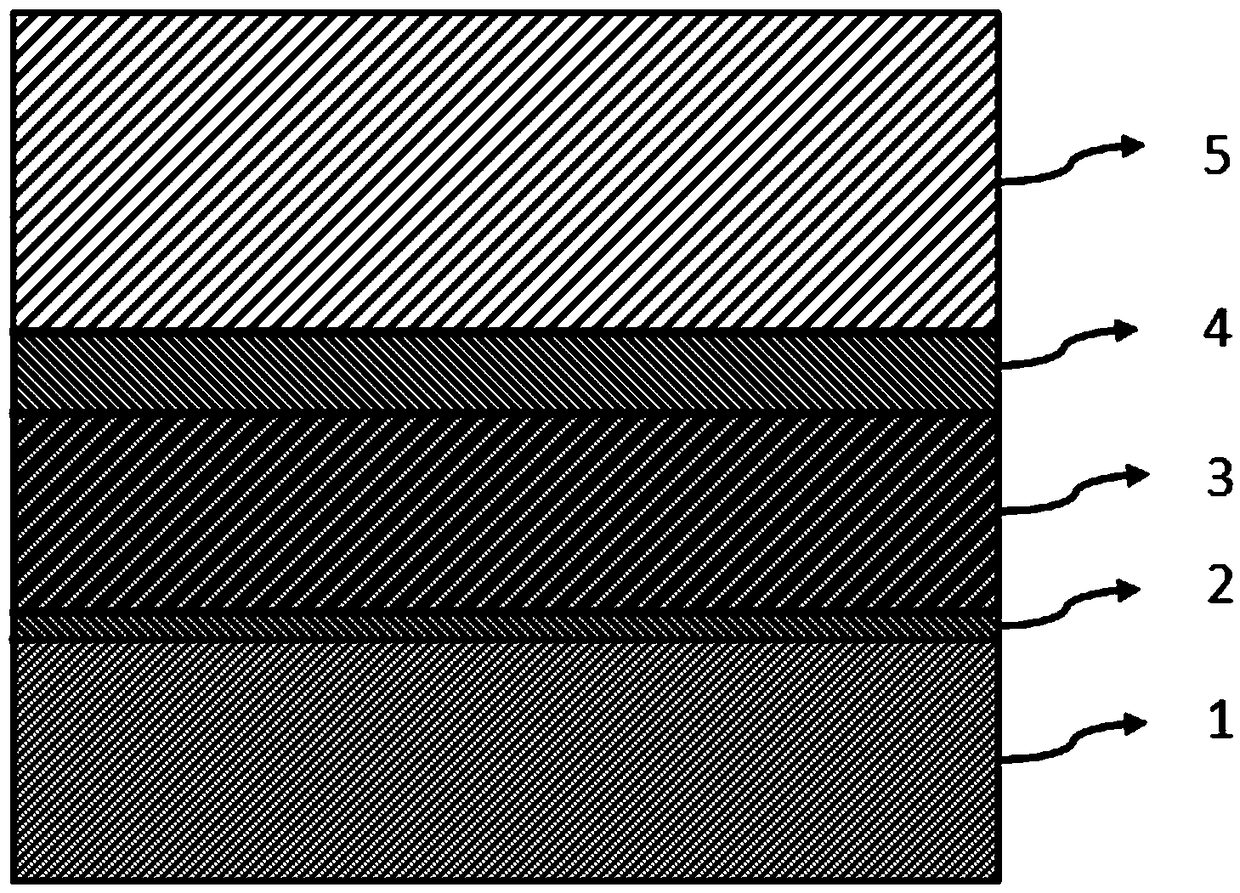

[0033] S1: Such as figure 1 As shown, a low-temperature growth GaN nucleation layer 2 is grown on a sapphire substrate 1, and the nucleation layer is annealed at a high temperature; the growth temperature of the GaN nucleation layer is 500° C., the thickness is 15 nm, and the pressure is 150 Torr. The annealing temperature is 900℃ and the time is 20min. The annealed nucleation layer transforms into an island structure with a certain grain orientation;

[0034] S2: Such as figure 1 As shown, an unintentionally doped GaN buffer layer 3 is grown on the nucleation layer 2. The growth temperature is 1150℃, the thickness is 0.2μm, and the pressure is 50 Torr;

[0035] S3: Such as figure 1 As shown, a medium-high temperature GaN layer 4 is grown on the GaN buffer layer 3. The growth temperature is 750°C and the thickness is 2nm. The medium and high temperature GaN layer is beneficial to reduce the thermal stress...

Embodiment 2

[0040] A method for preparing an InGaN film includes the following steps:

[0041] S1: Such as figure 1 As shown, a low-temperature growth GaN nucleation layer 2 is grown on a silicon substrate 1, and the nucleation layer is annealed at a high temperature; the growth temperature of the GaN nucleation layer is 700° C., the thickness is 50 nm, and the pressure is 700 Torr. The annealing temperature is 1100℃, and the time is 0.5min. The annealed nucleation layer transforms into an island structure with a certain grain orientation;

[0042] S2: Such as figure 1 As shown, an unintentionally doped GaN buffer layer 3 is grown on the nucleation layer 2. The growth temperature is 1120°C, the thickness is 4μm, and the pressure is 700 Torr;

[0043] S3: Such as figure 1 As shown, a medium-high temperature GaN layer 4 is grown on the GaN buffer layer 3. The growth temperature is 1050°C and the thickness is 200 nm. The medium and high temperature GaN layer is beneficial to reduce the thermal ...

Embodiment 3

[0048] A method for preparing an InGaN film includes the following steps:

[0049] S1: Such as figure 1 As shown, a low-temperature growth GaN nucleation layer 2 is grown on a zinc oxide substrate 1, and the nucleation layer is annealed at a high temperature; the growth temperature of the GaN nucleation layer is 600° C., the thickness is 30 nm, and the pressure is 400 Torr. The annealing temperature is 1000°C and the time is 5 min. The annealed nucleation layer transforms into an island structure with a certain grain orientation;

[0050] S2: Such as figure 1 As shown, an unintentionally doped GaN buffer layer 3 is grown on the nucleation layer 2. The growth temperature is 950°C, the thickness is 3μm, and the pressure is 300 Torr;

[0051] S3: Such as figure 1 As shown, a medium-high temperature GaN layer 4 is grown on the GaN buffer layer 3. The growth temperature is 800°C and the thickness is 5nm. The medium and high temperature GaN layer is beneficial to reduce the thermal str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com