AIN epitaxial thin film preparation method

A technology of epitaxial film and nucleation layer, which is applied in semiconductor/solid-state device manufacturing, coating, gaseous chemical plating, etc., can solve the problem of high dislocation density of AlN film and achieve low dislocation density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

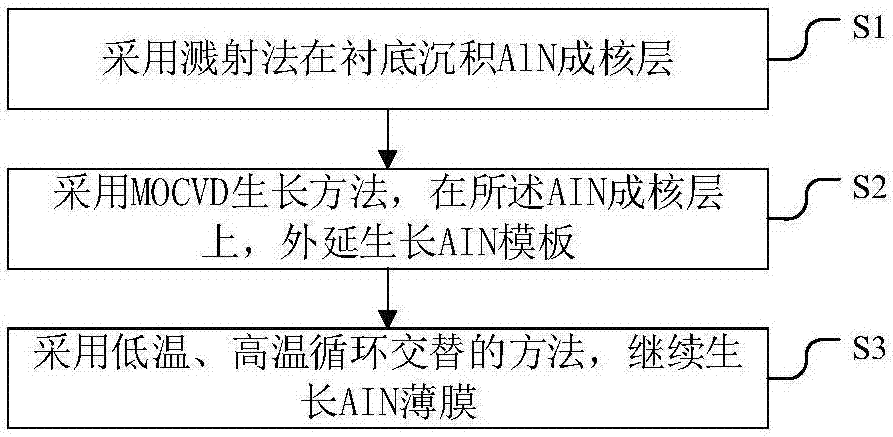

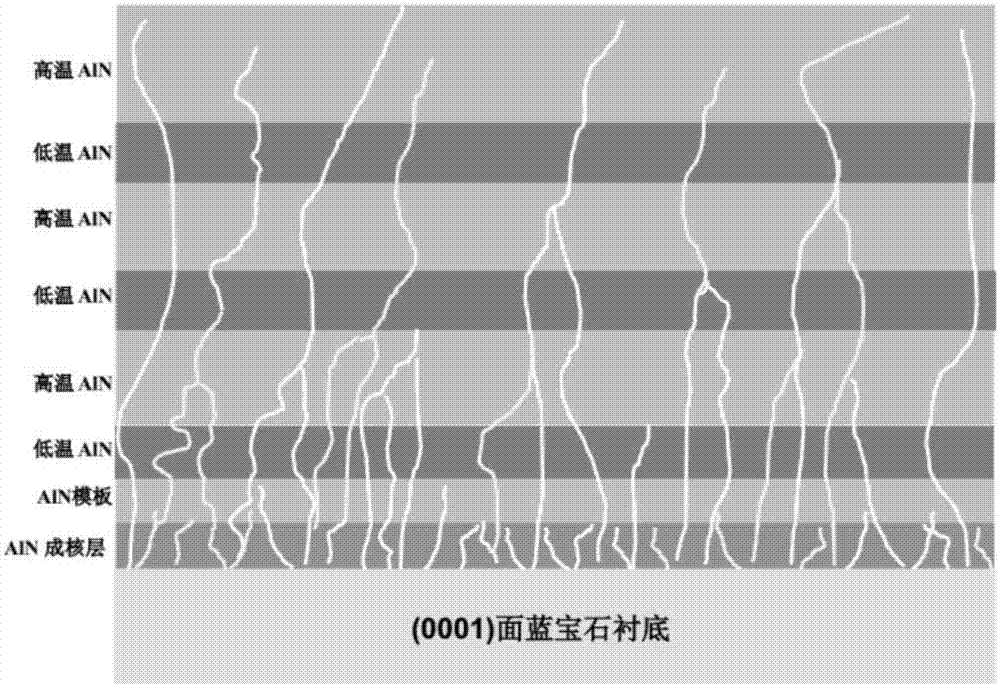

[0031] figure 1 It shows a schematic flow chart of a method for preparing an AlN epitaxial thin film provided by an embodiment of the present invention, see figure 1 , the method specifically includes the following steps:

[0032] S1. Depositing an AlN nucleation layer on the cleaned c-plane sapphire substrate by sputtering;

[0033] S2. Using the MOCVD growth method to epitaxially grow an AIN template on the AIN nucleation layer;

[0034] S3. Continue to grow the AIN thin film by adopting the low temperature and high temperature cycle alternating method.

[0035] Steps S1-S3 are described in detail below:

[0036] In the step S1, the thickness of the nucleation layer is 5-400nm, and the substrate temperature is 300-900°C.

[0037] Described step S2 comprises:

[0038] Passing hydrogen gas into the reaction chamber of the MOCVD equipment where the substrate is placed, keeping the temperature in the reaction chamber at 1200-1250°C and the pressure at 50-100mbar;

[0039] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com