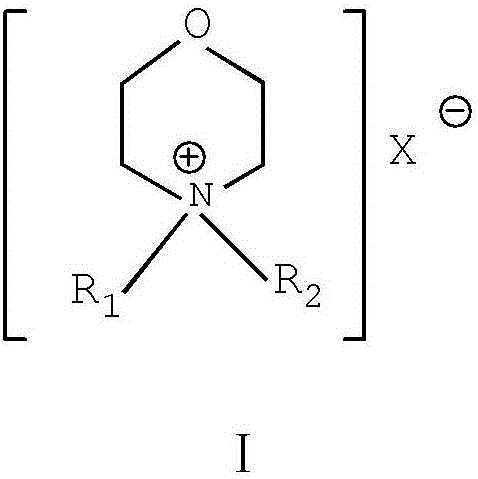

Double-effect composite hydrate inhibitor and preparation method thereof

A hydrate inhibitor and composite technology, applied in drilling compositions, chemical instruments and methods, organic chemistry, etc., can solve the problems of poor biodegradability and inability of compounds to prevent growth and aggregation, delay Effect of nucleation time and suppression cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

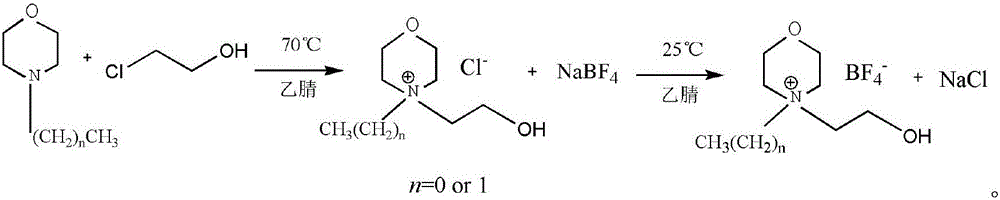

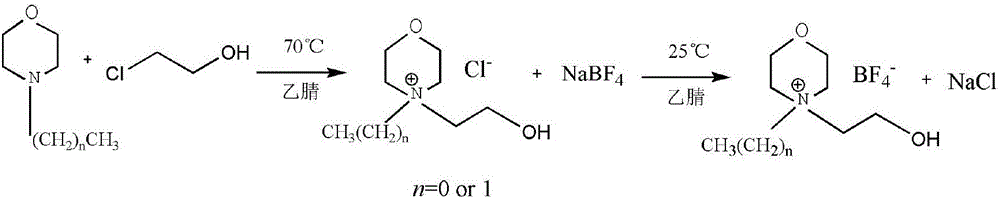

[0033] Example 1: Preparation method of double-effect compound hydrate inhibitor

[0034] The synthetic route is as follows:

[0035]

[0036] Include the following steps:

[0037] (1) Add 0.3 mol of alkylmorpholine derivatives, 0.45 mol of 2-chloroethanol, and 200 mL of acetonitrile into a 500 mL three-necked reaction flask equipped with a reflux condenser, a thermometer, a stirrer and a nitrogen inlet and outlet. Introduce nitrogen and heat to 70°C, stir and react for 48 hours; use a separatory funnel to separate the product from residual 2-chloroethanol and acetonitrile, collect and wash with acetone, and then distill under reduced pressure to further remove volatile organic impurities , drying at 45-50° C. for 24 hours under a vacuum condition of -0.08 to -0.1 MPa to obtain a hydroxylated morpholine chloride salt with a higher purity, and the yield is about 80%;

[0038] (2) Mix the hydroxylated morpholine chloride salt obtained in step (1) with 0.3 mol sodium tetrafl...

Embodiment 2

[0040] Embodiment 2: inhibition effect evaluation

[0041] Use the hydrate inhibitor performance evaluation test system to test the effect of the inhibitor, and the hydrate inhibitor performance evaluation test system includes a high-pressure reaction kettle, a buffer tank, a constant temperature water bath, a vacuum pump, a magnetic stirring system, a manual booster pump, and a gas flow meter. , gas cylinders, temperature and pressure sensors and data acquisition systems, etc. Among them, the core equipment high-pressure reactor is made of stainless steel 316 material, and the maximum working pressure can reach 25MPa. The constant temperature water bath provides -20~100°C refrigerant circulating fluid for the high pressure reactor, and the speed adjustment range of the magnetic stirring system is 0~1000r / min. The temperature in the high-pressure reactor is measured by a Pt100 platinum resistance temperature sensor, the temperature measurement accuracy is ±0.1°C, and the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com