System for storing and transporting natural gas based on hydrate method and use method of system

A technology for natural gas and hydrate, which is applied in the petroleum industry, solid fuels, fuels, etc., can solve the problems of simple preparation methods and few processes, blockage of water circulation loops, etc., and achieves the effects of shortening nucleation time, enhancing efficiency, and facilitating industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

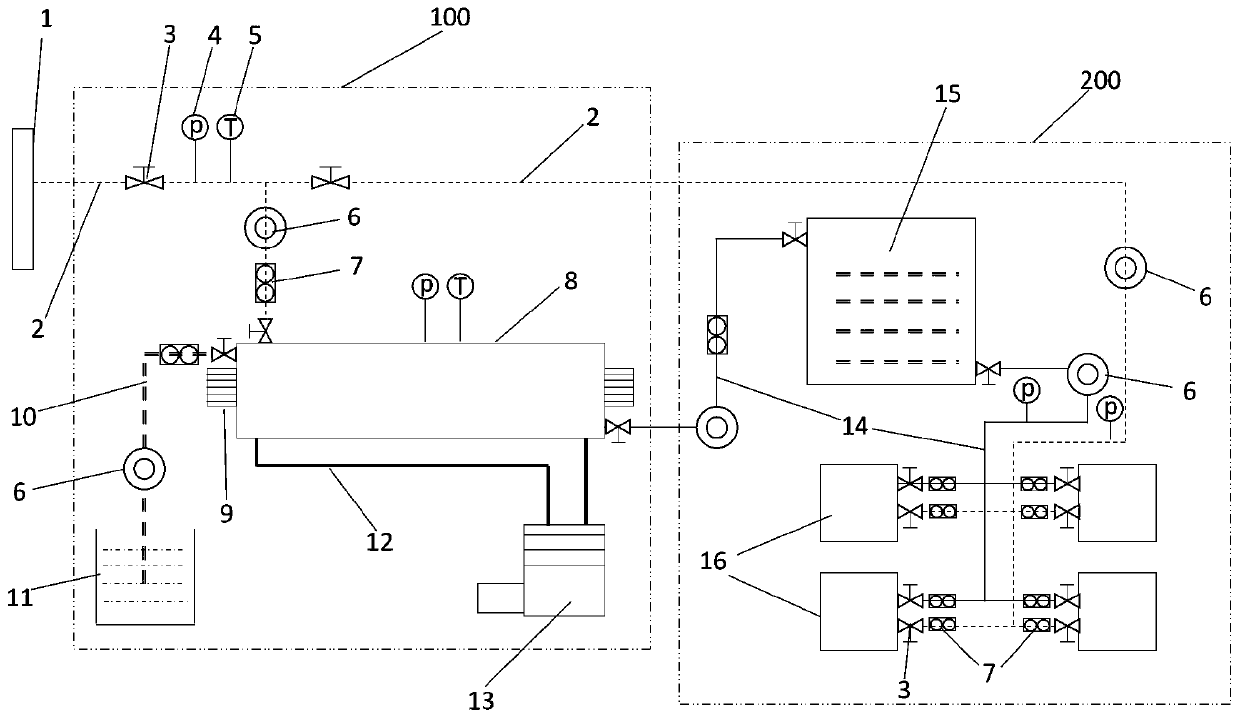

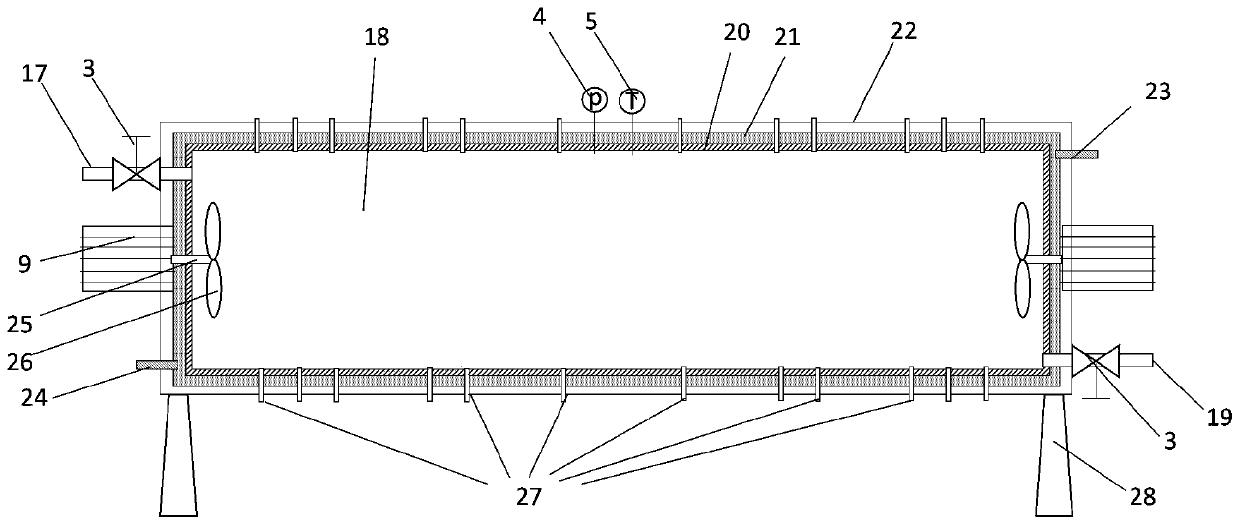

[0104] The using method of embodiment 1 is divided into the following steps:

[0105] Step 1. In the hydrate slurry preparation process, the configured water in the water tank 11 is pumped through the configured water booster pump 6, and the configured water is pumped into the hydrate slurry generating device 8 through the water delivery pipeline 10, so that the configured water fills the cavity of the slurry generating device Chamber 18, inject natural gas into the hydrate slurry generating device 8 through the gas booster pump 6 and discharge the configured water, adjust the configured water stock to 0.8 times the volume of the hydrate slurry generating device 8 through gas injection and drainage, and pass through the refrigeration unit 13 Adjust the reaction temperature in the hydrate slurry generating device 8 to 2°C, and inject natural gas through the gas injection ports 27 arranged in steps. The volume of the hydrate slurry generating device 8 changes by 1 MPa, and the h...

Embodiment 2

[0114] The using method of embodiment 2 is divided into the following steps:

[0115] Step 1. In the hydrate slurry preparation process, the configured water in the water tank 11 is pumped through the configured water booster pump 6, and the configured water is pumped into the hydrate slurry generating device 8 through the water delivery pipeline 10, so that the configured water fills the cavity of the slurry generating device Chamber 18, inject natural gas into the hydrate slurry generating device 8 through the gas booster pump 6 and discharge the configured water, adjust the configured water stock to 0.8 times the volume of the hydrate slurry generating device 8 through gas injection and drainage, and pass through the refrigeration unit 13 Adjust the reaction temperature in the hydrate slurry generating device 8 to 2°C, and inject natural gas through the gas injection ports 27 arranged in steps. The volume of the hydrate slurry generating device 8 changes by 1 MPa, and the h...

Embodiment 3

[0124] The using method of embodiment 3 is divided into the following steps:

[0125] Step 1. In the hydrate slurry preparation process, the configured water in the water tank 11 is pumped through the configured water booster pump 6, and the configured water is pumped into the hydrate slurry generating device 8 through the water delivery pipeline 10, so that the configured water fills the cavity of the slurry generating device Chamber 18, inject natural gas into the hydrate slurry generating device 8 through the gas booster pump 6 and discharge the configured water, adjust the configured water stock to 0.8 times the volume of the hydrate slurry generating device 8 through gas injection and drainage, and pass through the refrigeration unit 13 Adjust the reaction temperature in the hydrate slurry generating device 8 to 2°C, and inject natural gas through the gas injection ports 27 arranged in steps. The volume of the hydrate slurry generating device 8 changes by 1 MPa, and the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com