Accelerant for generating gas hydrate

A gas hydrate and accelerator technology, applied in the field of accelerators, can solve the problems of high energy consumption, accelerated local reaction heat, etc., and achieve the effects of wide temperature range, shortened nucleation time, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

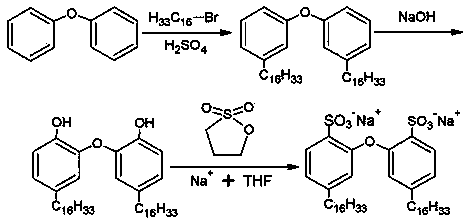

Method used

Image

Examples

Embodiment 1

[0020] Based on the total mass of 1000g, use an electronic balance to weigh 0.5g of nano-activated carbon, 0.1g of alkyl diphenyl ether disulfonate surfactant and 999.4mL of distilled water at the ratio of 0.05%, 0.01%, and 99.94% respectively; The nano activated carbon powder of g is dissolved in the distilled water of 999.4mL, and stirs 15min with the rotating speed of 500rpm with magnetic stirrer, then adds the alkyl diphenyl ether disulfonate surfactant solid of 0.1g and continues stirring, continues 30min, finally The stirred liquid is ultrasonically dispersed.

Embodiment 2

[0022] Based on the total mass of 1000g, use an electronic balance to weigh 1.5g of nano-activated carbon, 0.8g of alkyl diphenyl ether disulfonate surfactant and 997.7mL of distilled water at the ratio of 0.15%, 0.08%, and 99.77% respectively; The nano activated carbon powder of g is dissolved in the distilled water of 997.7mL, and stirs 15min with the rotating speed of 500rpm with magnetic stirrer, then adds the alkyl diphenyl ether disulfonate surfactant solid of 0.8g and continues stirring, continues 30min, finally The stirred liquid is ultrasonically dispersed.

Embodiment 3

[0024] Based on the total mass of 1000g, use an electronic balance to weigh 1.0g of nano-activated carbon, 0.2g of alkyl diphenyl ether disulfonate surfactant and 998.8mL of distilled water at the ratio of 0.1%, 0.02%, and 99.88% respectively; The nano activated carbon powder of g is dissolved in the distilled water of 998.8mL, and stirs 15min with the rotating speed of 500rpm with magnetic stirrer, then adds the alkyl diphenyl ether disulfonate surfactant solid of 0.2g and continues stirring, continues 30min, finally The stirred liquid is ultrasonically dispersed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com