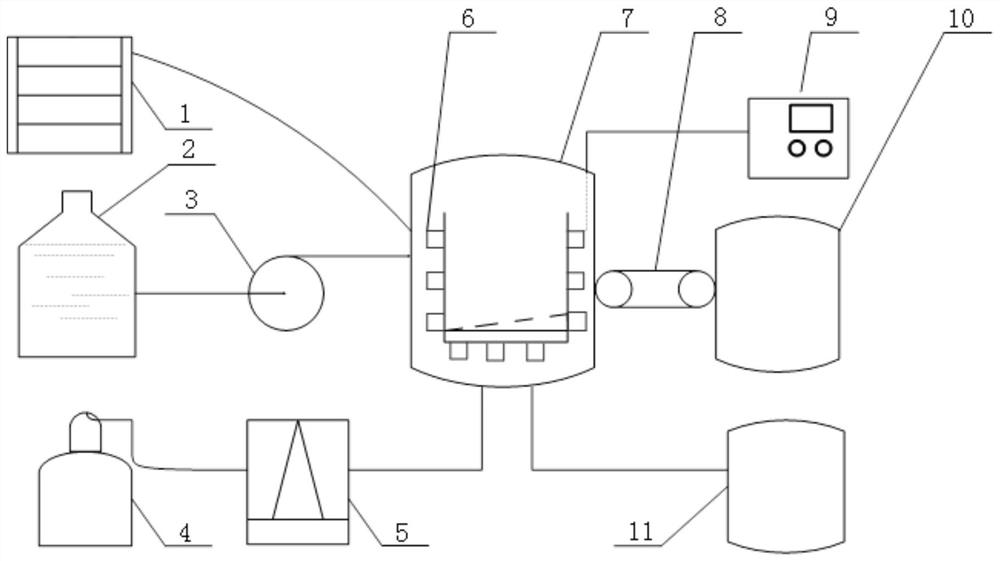

Variable-frequency ultrasonic-assisted hydrate liquid food concentration device and method

A liquid food, frequency conversion ultrasonic technology, applied in food preservation, food science, application, etc., can solve the problems of limited microbial killing effect, excessive hydrate crystals, hydrate entrainment phenomenon, etc., to reduce the limited lethal effect and promote The formation of hydrogen bonds, the promotion of nucleation and the effect of controlling the crystal form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A method for frequency conversion ultrasonic assisted hydrate concentration of liquid food in this embodiment comprises the following steps:

[0049] The litchi variety "Guiwei" is taken from a commercial orchard in Maoming, Guangdong, with a maturity of 80% to 90%. After picking, refrigerate them in foam boxes, and transport them to the laboratory within 6 hours. Fruits with uniform size, shape, and color are strictly selected for the fruit juice hydration concentration experiment. After the lychees are shelled and cored, they are homogenized with a colloid mill and filtered to obtain lychee juice with a solid content of 16 ° brix, and placed in a 1 ° C refrigerator for pre-cooling. Turn on the condensation circulation equipment connected to each tank, set the temperature of the feed tank and the concentration processor to 1°C, after the temperature reaches the set temperature and is balanced and stable, take 4L of pre-cooled cinnamon juice and pump it into the concent...

Embodiment 2

[0051] A method for frequency conversion ultrasonic assisted hydrate concentration of liquid food in this embodiment comprises the following steps:

[0052] Blueberry anthocyanin extract, solid content 4 ° brix, placed in a 4 ° C refrigerator for pre-cooling. Turn on the condensation circulation equipment connected to each tank, set the temperature of the feed tank and the concentration processor to 4°C, after the temperature reaches the set temperature and is balanced and stable, take 4L of the pre-cooled blueberry anthocyanin extract from the feed tank Pump into the inner cavity of the enrichment processor; open the gas cylinder at the same time, and adjust the diameter of the bubble to be 10 2 nm, after the pressure reaches 35bar, continue to inflate for 1min, at the same time give ultrasonic treatment, close the air valve; give 0.35W / cm 2 Ultrasonic treatment for 60s; 0.9W / cm in the phase transition stage 2 Ultrasonic treatment for 80s; crystal growth stage to give 1.4W / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com