Method of synthesizing IM-5 molecular sieve by using composite template

A composite template agent, IM-5 technology, applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of IM-5 molecular sieve synthesis research, no related reports, unfavorable industrial scale-up, etc., to shorten the crystallization time and broaden the Proportion range, the effect of suppressing the formation of miscellaneous crystal phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

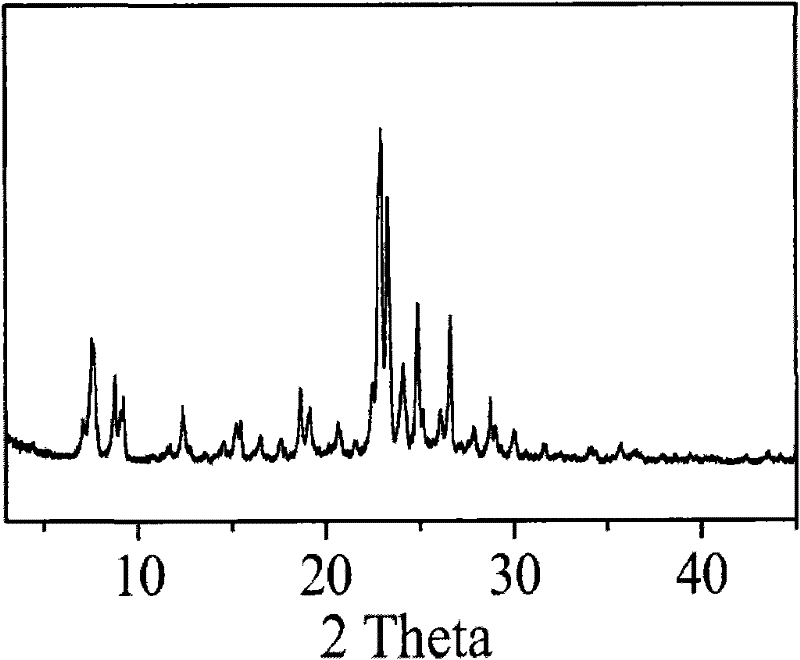

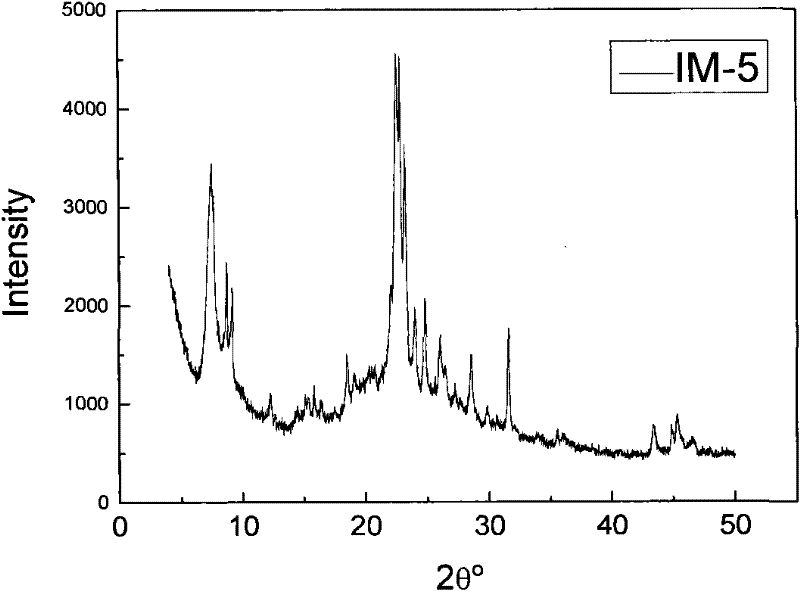

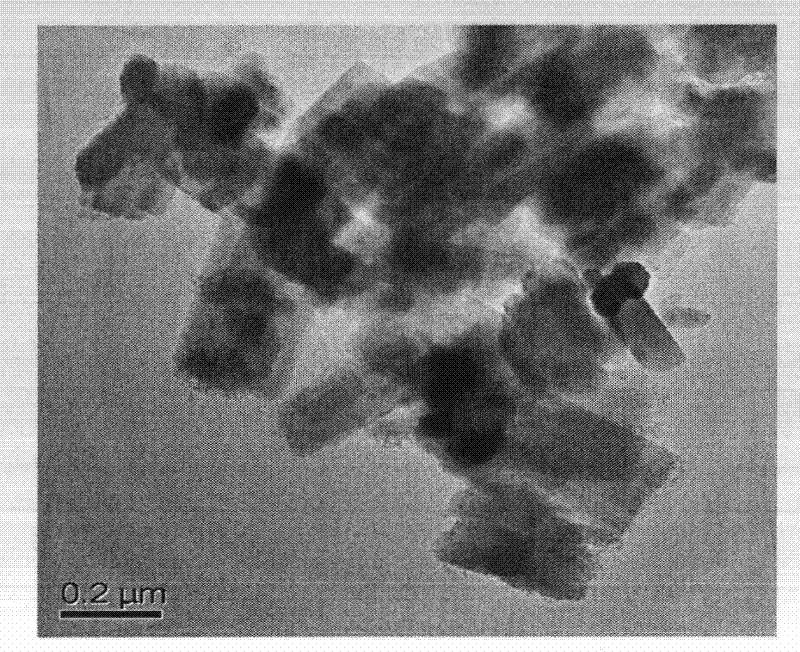

[0054] Example 1 illustrates the effect of the IM-5 molecular sieve synthesis method provided by the present invention.

[0055] (1) Preparation of sodium metaaluminate (NaAlO 2 ) solution

[0056] Weigh 194g of NaOH and dissolve it in about 500ml of deionized water, add 153g of pseudo-boehmite (66.3% solid content), and cook for 30min to obtain a clear and transparent solution. The obtained liquid was dubbed into 1L solution while it was hot, and cooled for later use.

[0057] (2) Dissolve 2.95g NaOH in 20.65g deionized water, then add 4.01g NaAlO 2 Aqueous solution, 27.40g 1,5-bis(N-methylpyrrolidine) pentane bromide salt aqueous solution and 7.58g tetrapropylammonium bromide aqueous solution are mixed uniformly, under the condition of stirring, slowly dropwise add 40g alkaline silica sol, A gel was made and stirring was continued for 2 hours. The molar composition of the reaction mixture is: SiO 2 :Al 2 o 3 :Na 2 O:R1:R2:H 2 O=60:1:13.5:9:3:1200. Transfer the prep...

Embodiment 2

[0059] Example 2 illustrates the effect of the IM-5 molecular sieve synthesis method provided by the present invention.

[0060] 2.23g NaOH is dissolved in 15.63g deionized water, then add the NaAlO prepared by 6.02g embodiment 1 step (1) 2 Aqueous solution, 27.40g 1,5-bis(N-methylpyrrolidine) pentane bromide aqueous solution and 12.49g tetrapropyl ammonium hydroxide aqueous solution are mixed uniformly, under the condition of stirring, slowly dropwise add 40g alkaline silica sol, Then add SiO 2 The 5 wt% calcined IM-5 molecular sieve was used as a seed crystal to make a colloid, and the stirring was continued for 2 hours. The molar composition of the reaction mixture is: SiO 2 :Al 2 o 3 :Na 2 O:R1:R2:H 2 O=60:1.5:12:9:6:1200. Transfer the obtained colloid to a 50ml polytetrafluoroethylene-lined autoclave, rotate and crystallize at 160°C for 4 days, stop the crystallization reaction, wash and filter the product, and dry it overnight at 80°C to obtain IM -5 molecular si...

Embodiment 3

[0062] Example 3 illustrates the effect of the IM-5 molecular sieve synthesis method provided by the present invention.

[0063] 4.48g NaOH is dissolved in 43.19g deionized water, then add the NaAlO prepared by 2.01g embodiment 1 step (1) 2 Aqueous solution, 36.54g 1,5-bis(N-methylpyrrolidine)pentane bromide salt aqueous solution and 22.74g tetrapropylammonium bromide aqueous solution are mixed uniformly, under the condition of stirring, slowly dropwise add 40g alkaline silica sol, A gel was made and stirring was continued for 2 hours. The molar composition of the reaction mixture is: SiO 2 :Al 2 o 3 :Na2O:R1:R2:H 2 O=60:0.5:18:12:9:1800. Transfer the obtained colloid to a 50ml polytetrafluoroethylene-lined autoclave, rotate and crystallize at 140°C for 7 days, stop the crystallization reaction, wash and filter the product, and dry it overnight at 80°C to obtain IM -5 molecular sieves.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com