Hybrid material containing metal organic framework material, and preparation method thereof

A technology of metal-organic frameworks and hybrid materials, applied in the fields of alkali metal compounds, chemical instruments and methods, alkali metal oxides/hydroxides, etc., can solve the problem of low physical and chemical properties, high carboxyl arrangement density, and reduced adsorption capacity To achieve the effect of shortening the crystal nucleation time, enhancing the hydrogen bond interaction, and enhancing the mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

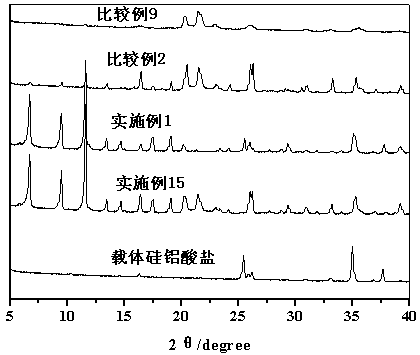

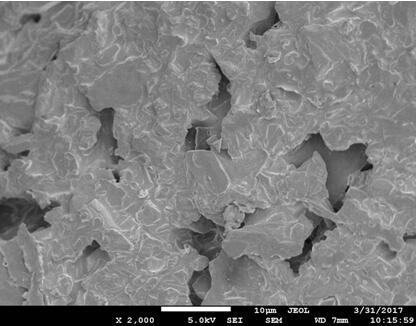

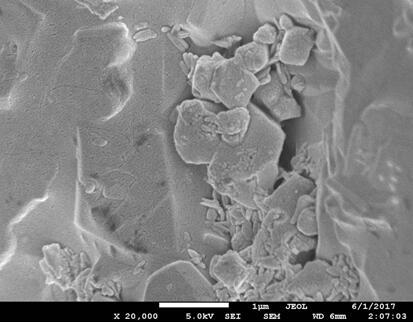

[0035] Take 20g of carrier aluminosilicate plate, its thickness is 15mm, γ-alumina mass content and silica mass content are 70% and 30% respectively, and its total pore volume, average pore diameter, specific surface area and compressive strength are 0.27cm 3 / g, 1650nm, 1.25m 2 / g and 0.02MPa. The aluminosilicate plate was placed in 200 g of a hydrochloric acid solution with a mass concentration of 15% for 4 hours, taken out, washed with deionized water until neutral, and dried at 100 °C for 10 hours for use.

[0036] 1 g of trimesic acid was placed in 10 g of anhydrous ethanol solvent, and stirred at room temperature to obtain an ethanol solution of trimesic acid. Take 10g of acidified aluminosilicate plate and immerse it in trimesic acid ethanol solution for 10h.

[0037] 0.3 g of copper nitrate trihydrate was placed in 3 g of deionized water, and stirred at room temperature to obtain an aqueous solution of copper nitrate trihydrate. The soaked aluminosilicate plate was...

Embodiment 2

[0040] Same as Example 1, the difference is that the acid treatment adopts sulfuric acid to obtain the hybrid material B containing the metal-organic framework material.

Embodiment 3

[0042] Same as Example 1, the difference is that the acid treatment adopts nitric acid to obtain the hybrid material C containing the metal-organic framework material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com