High-performance Al-Ti-V-B alloy refiner and preparation method and application thereof

A technology of al-ti-v-b and refining agent, which is applied in the field of aluminum alloy processing, can solve the problems of changing furnace temperature, cumbersome process, reducing refining efficiency, etc., and achieves industrial production improvement, simplified preparation process and high refining effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1A

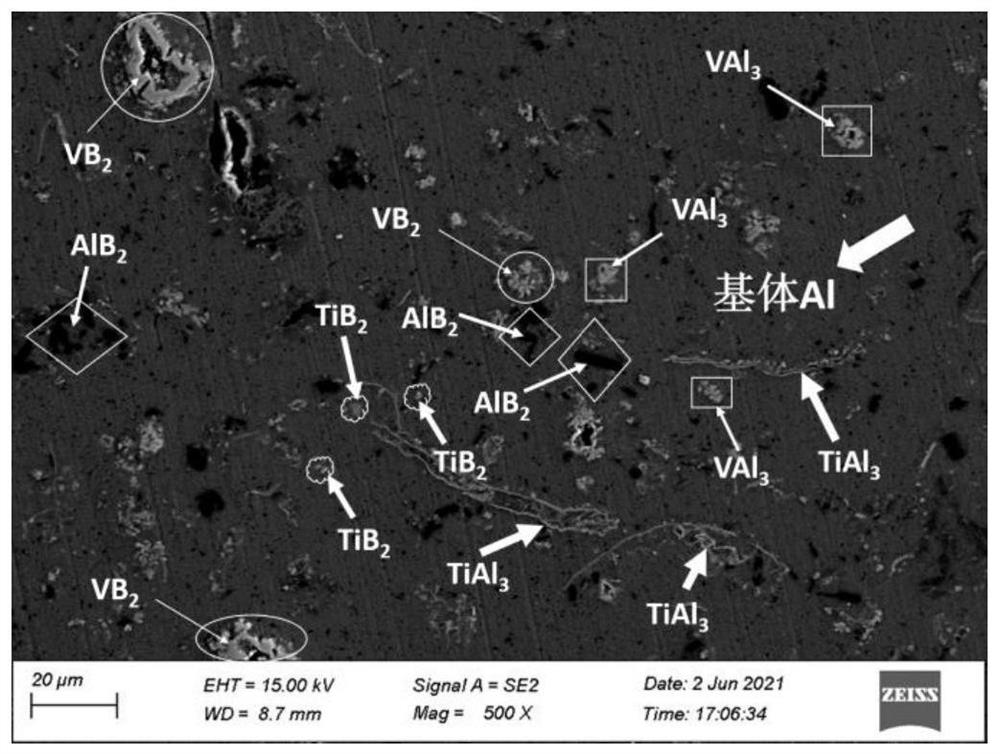

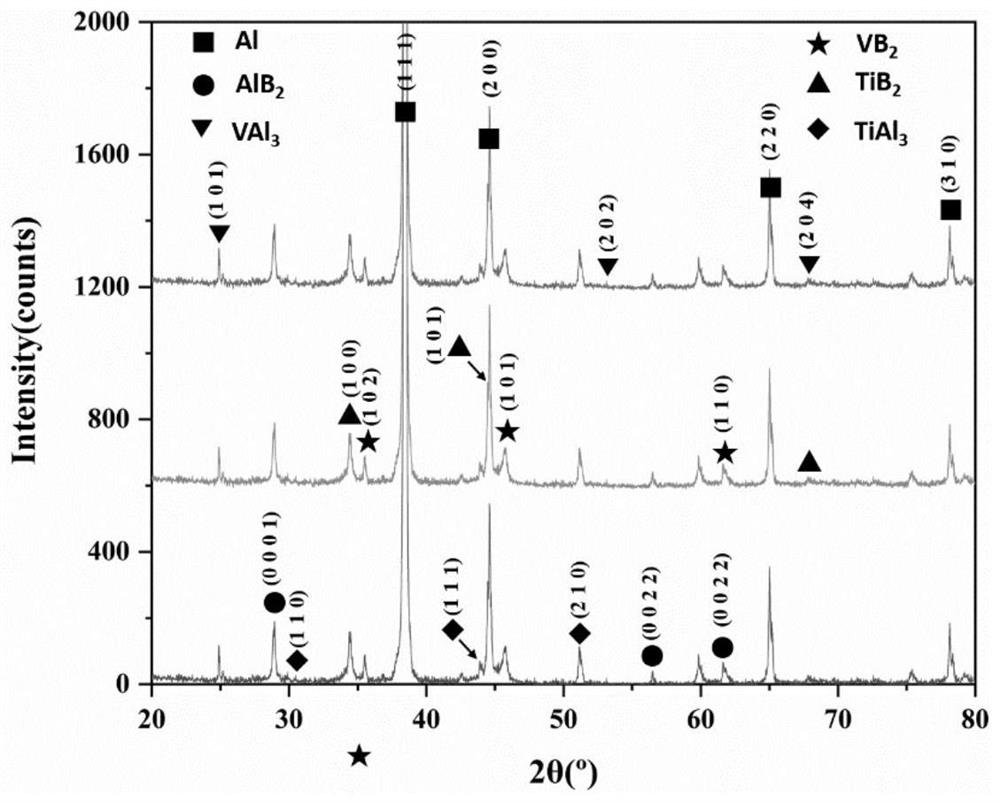

[0029] The preparation method of embodiment 1Al-1Ti-2V-3B refiner

[0030] Al-1Ti-2V-3B refiner composition: in terms of mass percentage: Ti: 1.0wt.%; V: 2.0wt.%, B: 3.0wt.%, and the unavoidable impurity content is less than 0.1wt.%, The balance is Al. Weigh the raw materials respectively according to the composition of the refiner.

[0031] The preparation steps of Al-1Ti-2V-3B refiner:

[0032] (1) After melting Al at 750-780°C, add V powder and KBF after heating to 830°C 4 Powder and K 2 TiF 6 Powder mixture, stirred for 60s every 15min and heated for 130min to obtain a uniform Al-1Ti-2V-3B alloy melt;

[0033] (2) Cast the alloy melt obtained in step (1) into a cast iron mold preheated at 200° C., and solidify to obtain an Al-1Ti-2V-3B refiner.

[0034] Al-1Ti-2V-3B refiner refining Al-8Si alloy method:

[0035] Put 300 grams of Al-8Si alloy into a graphite crucible and heat and melt it in a resistance furnace at 750°C, then add 4.5g of Al-1Ti-2V-3B refiner, stir an...

Embodiment 2

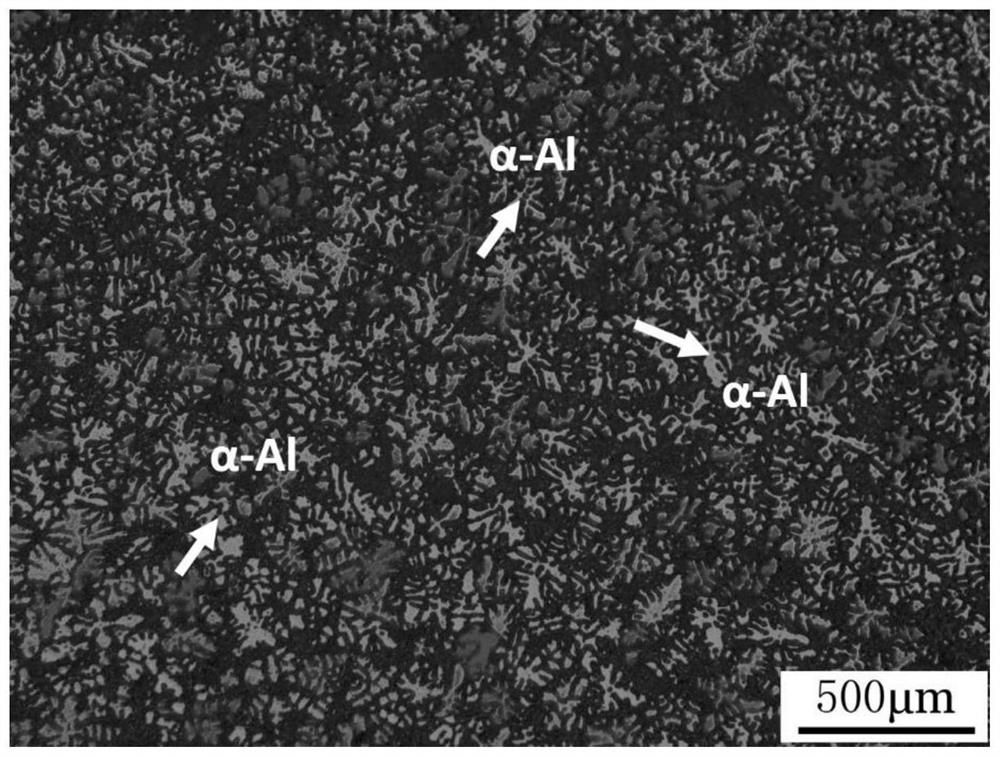

[0039] Al-1Ti-2V-3B refiner refining Al-5Si alloy method:

[0040] Put 300 grams of Al-5Si alloy into a graphite crucible and heat and melt it in a resistance furnace at 750°C, then add 4.5g of the Al-1Ti-2V-3B refiner prepared by the method in Example 1, after stirring and holding at 720°C for 45min The mixed melt is obtained, and then poured into a cast iron mold preheated at 200° C. for solidification to obtain a refined Al-5Si alloy ingot. The α-Al grain size of the refined Al-5Si alloy is about 154 μm.

Embodiment 3

[0041] The preparation method of embodiment 3Al-2Ti-2V-4B refiner

[0042] Al-2Ti-2V-4B refiner composition: in terms of mass percentage: Ti: 2.0wt.%; V: 2.0wt.%, B: 4.0wt.%, and the unavoidable impurity content is less than 0.1%, the balance for Al. Weigh the raw materials respectively according to the composition of the refiner.

[0043] The preparation steps of Al-2Ti-2V-4B refiner:

[0044] (1) After melting Al at 750-780°C, add V powder and KBF after heating to 800°C 4 Powder and K 2 TiF 6 Powder mixture, stirring for 80s every 20min and heating reaction for 150min to obtain a uniform Al-2Ti-2V-4B alloy melt;

[0045] (2) Cast the alloy melt obtained in step (1) into a cast iron mold preheated at 250° C., and solidify to obtain an Al-2Ti-2V-4B refiner.

[0046] The method of refinement Al-8Si alloy of Al-2Ti-2V-4B refiner adopts the same method as Al-1Ti-2V-3B refiner refinement Al-8Si alloy in embodiment 1, Al-2Ti- The effect of 2V-4B refining Al-8Si alloy is as a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com