Exchange-coupling composite magnetic recording medium and manufacturing method thereof

A magnetic recording medium and exchange coupling technology, applied in the field of magnetic storage, can solve the problems of weakening magnetic field, increasing distance between magnetic head and recording medium, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is further described below by means of examples.

[0030] Example description:

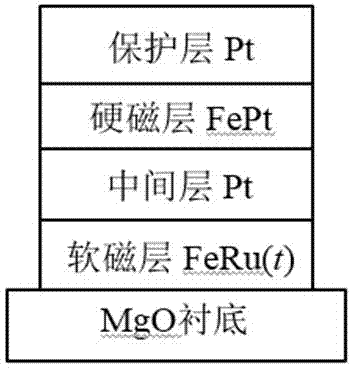

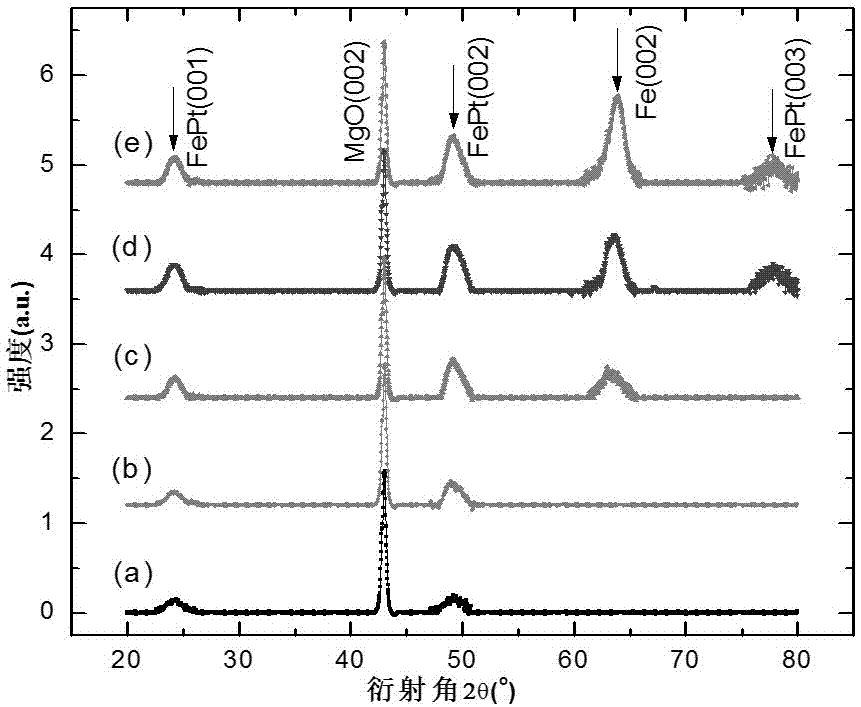

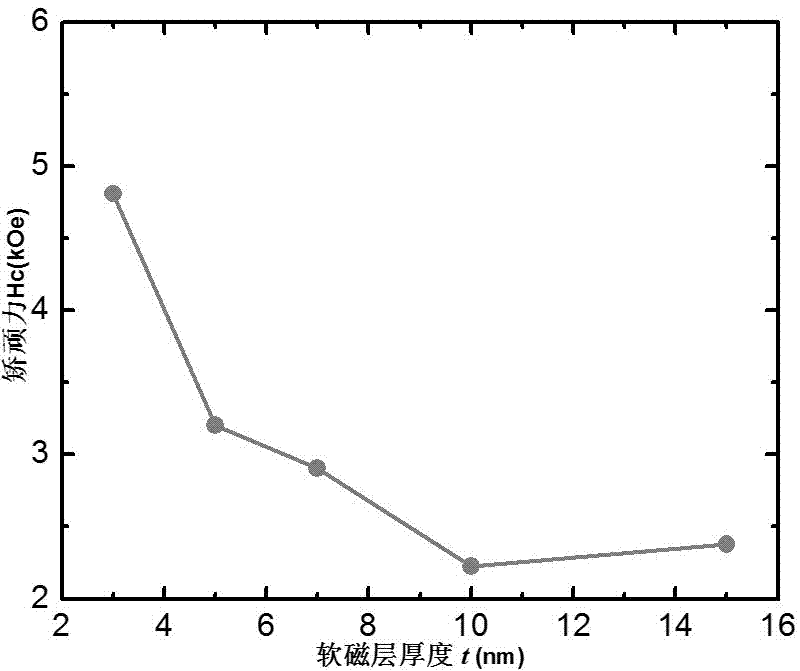

[0031] The thin film structure designed by the present invention is as follows figure 1 As mentioned above, the present invention is a new type of exchange-coupling composite film. First, it innovatively proposes to design an ECC film structure with a soft magnetic layer on the lower layer and a hard magnetic layer on the upper layer. The difficulty of realizing the composite structure lies in how to grow highly ordered FeRu layer on the soft magnetic layer. L 1 0 -FePt. We propose to insert a 3.0 nm-thick Pt intermediate layer between FeRu and FePt, which can well compensate for the lattice mismatch between the FeRu layer and the FePt layer interface, and inhibit the transfer of Fe to the FePt layer at high temperature. diffusion. figure 2 is FeRu( t ) / Pt(3.0 nm) / FePt(5.0 nm) thin film crystal structure measurement results, all thin film samples have FePt (001)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com