Low-temperature epitaxy preparation method of germanium-silicon film with high germanium content

A kind of content, germanium silicon technology, applied in the field of optimization of germanium silicon thin film growth conditions, can solve the problems of complex operation, high cost, waste of time, etc., and achieve the effect of simple operation, low cost and clear interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

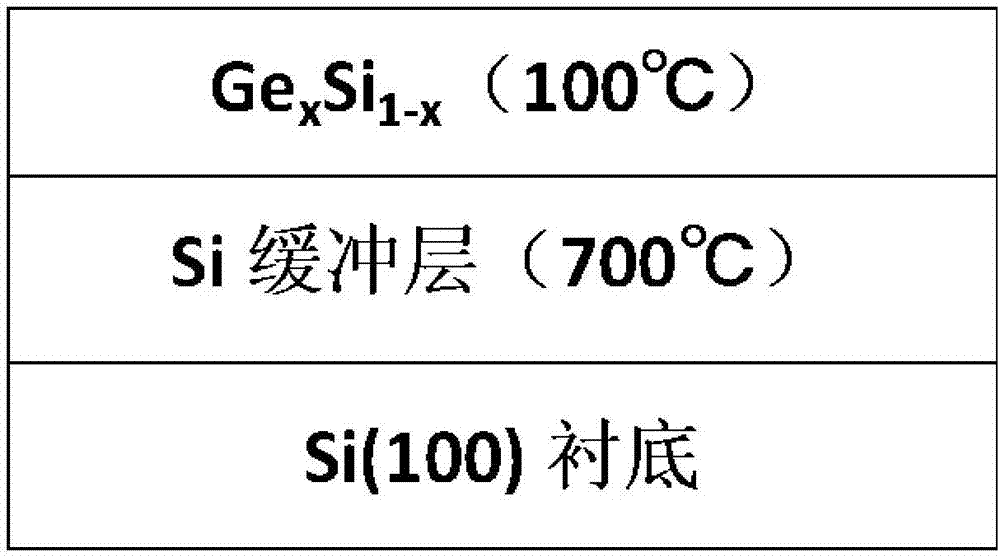

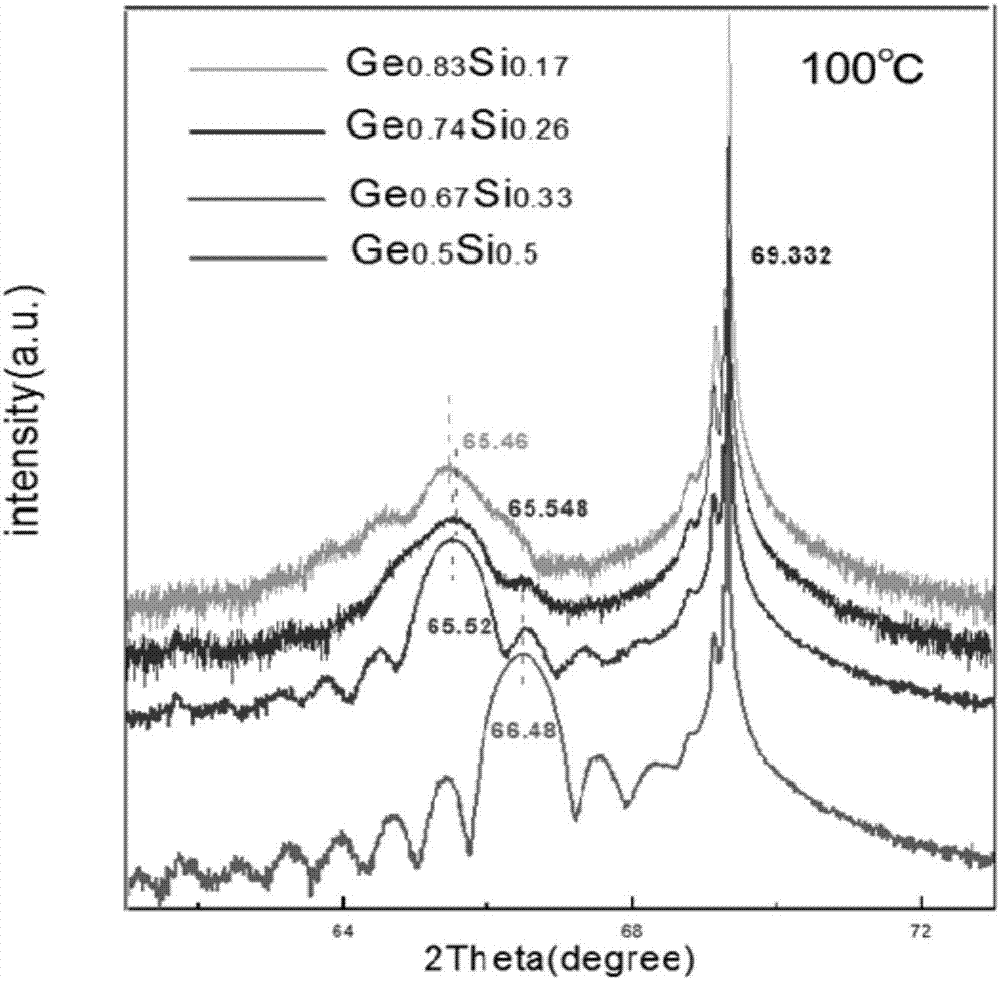

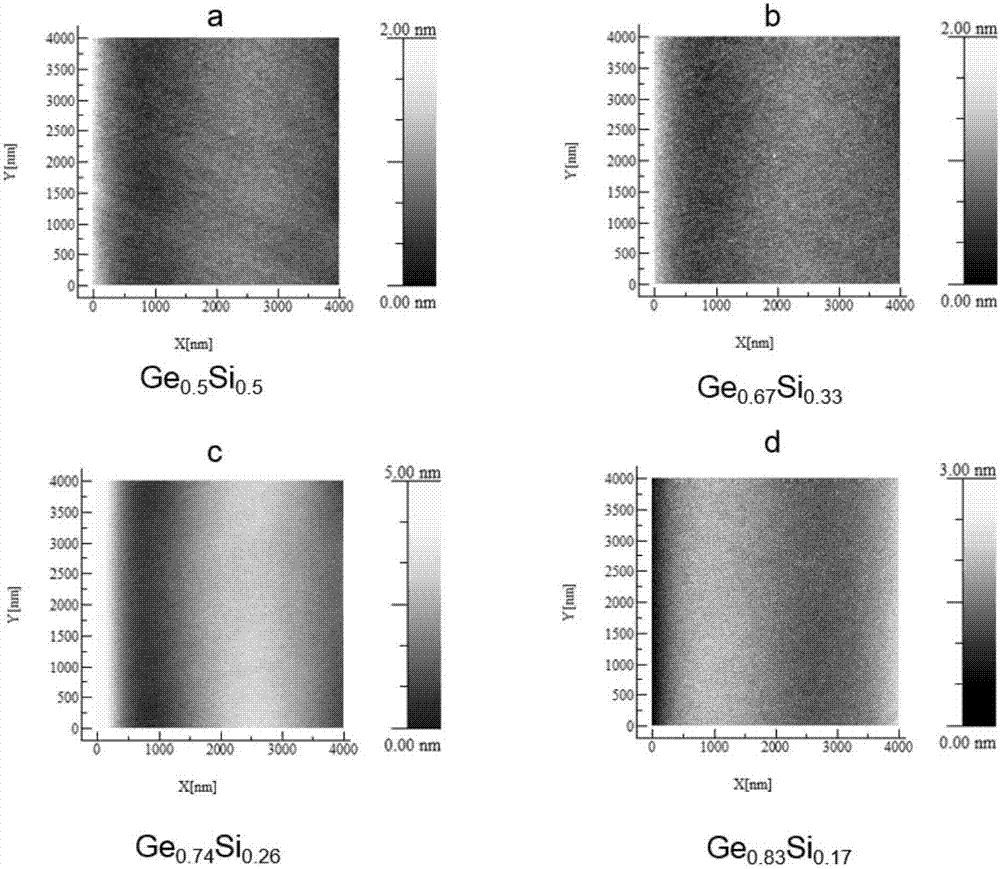

[0026] The invention provides a silicon germanium (Ge silicon) with adjustable lattice constant grown on a silicon chip by molecular beam epitaxy at low temperature. x Si 1-x ) film preparation method. figure 1 It is silicon germanium (Ge x Si 1-x ) Schematic diagram of the structure of the thin film, the specific preparation method is as follows:

[0027] Through solid-state source molecular beam epitaxy, the (100) crystal plane silicon substrate is first deoxidized, that is, the oxide on the surface is removed. Keeping the substrate rotating at a rotation speed of 10 rpm, the substrate heater was raised to 1350° C. for 10 minutes.

[0028] Then grow a 50nm Si buffer layer on the deoxidized Si(100) substrate by molecular beam epitaxy. The growth temperature was 700°C, and the growth rate was The Si source furnace used in this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com