Non-polar GaN thin film grown on LiGaO2 substrate, as well as manufacturing method and application thereof

A non-polar, substrate-based technology, applied in the field of non-polar GaN thin film and its preparation, can solve the problems of reduced carrier radiation recombination efficiency, unstable LED luminous wavelength, and affecting LED luminous efficiency, so as to eliminate quantum confinement Stark Effect, Ease of Obtaining, Effect of Improving Luminous Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

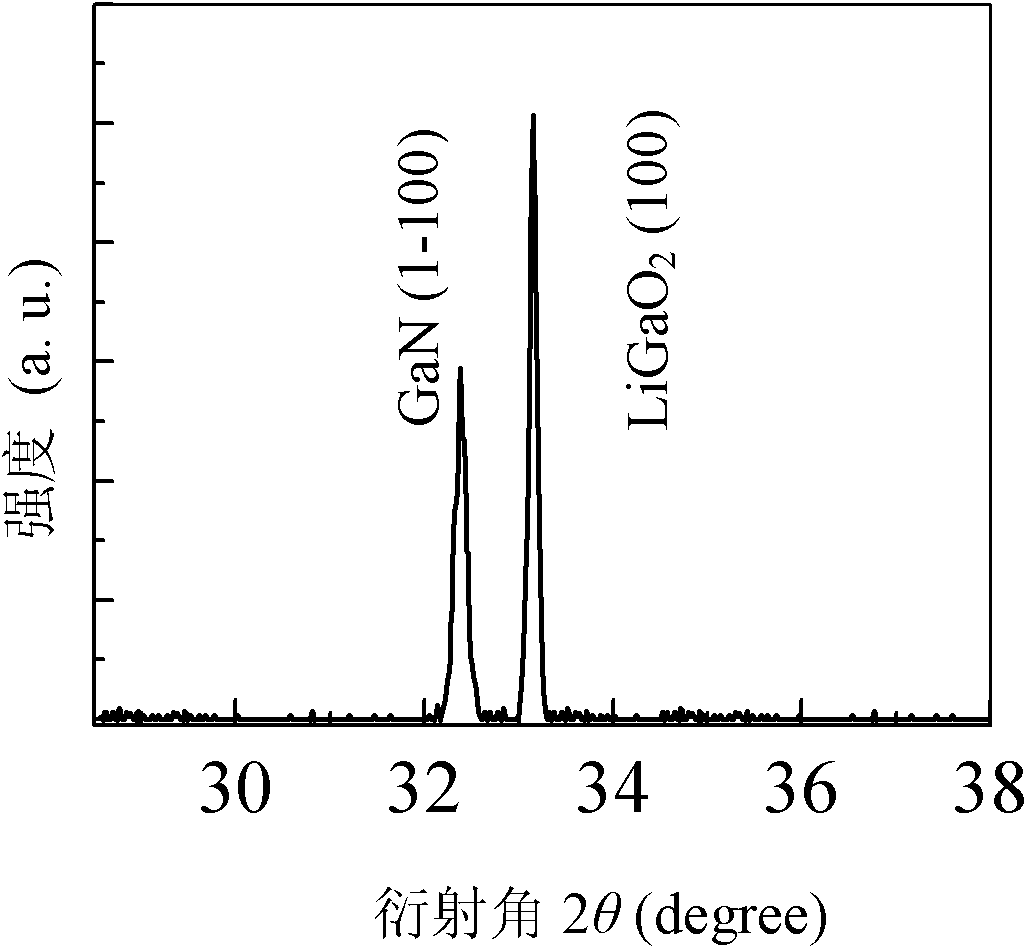

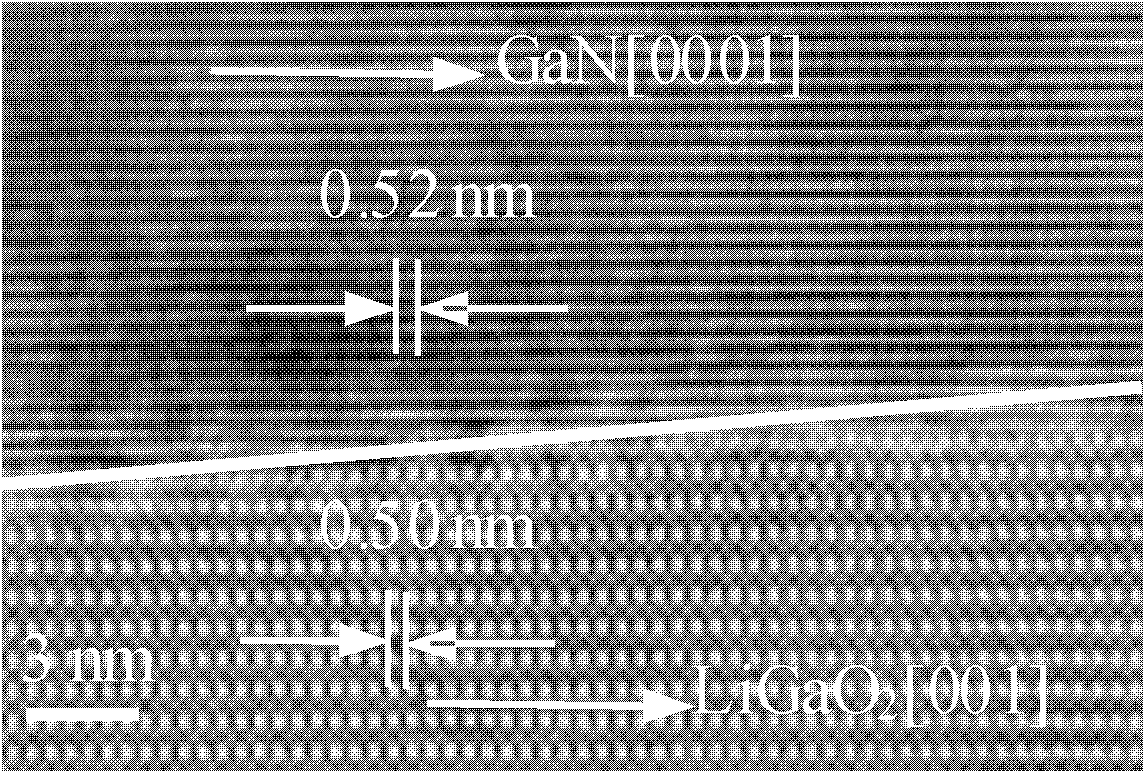

[0034] This example grows on LiGaO 2 The preparation method of the nonpolar GaN film on the substrate comprises the following steps:

[0035] (1) Select substrate and crystal orientation: use LiGaO 2 The substrate, the crystal orientation is (100) crystal plane deflected to (110) direction by 0.2°.

[0036] (2) Perform annealing treatment on the substrate: bake the substrate at 900° C. for 3-5 hours, and then cool it to room temperature in air.

[0037] (3) Clean the surface of the substrate: LiGaO 2The substrate was ultrasonically cleaned in deionized water for 5 minutes at room temperature to remove LiGaO 2 The dirt particles on the surface of the substrate are washed with hydrochloric acid, acetone, and ethanol in sequence to remove surface organic matter; the cleaned LiGaO 2 The substrate was blown dry with high-purity dry nitrogen; after that, the LiGaO 2 Put the substrate into a low-temperature molecular beam epitaxy growth chamber, raise the substrate temperature t...

Embodiment 2

[0046] This example grows on LiGaO 2 The preparation method of the nonpolar GaN film on the substrate comprises the following steps:

[0047] (1) Select substrate and crystal orientation: use LiGaO 2 The substrate, the crystal orientation is (100) crystal plane deflected to (110) direction by 0.2°.

[0048] (2) Perform annealing treatment on the substrate: bake the substrate at a high temperature of 1000° C. for 5 hours, and then air-cool to room temperature.

[0049] (3) Clean the surface of the substrate: LiGaO 2 The substrate was ultrasonically cleaned in deionized water for 10 minutes at room temperature to remove LiGaO 2 The dirt particles on the surface of the substrate are washed with hydrochloric acid, acetone, and ethanol in sequence to remove surface organic matter; the cleaned LiGaO 2 The substrate was blown dry with high-purity dry nitrogen; after that, the LiGaO 2 The substrate is placed in a low-temperature molecular beam epitaxy growth chamber. Under ultra-...

Embodiment 3

[0054] This example grows on LiGaO 2 The preparation method of the nonpolar GaN film on the substrate comprises the following steps:

[0055] (1) Select substrate and crystal orientation: use LiGaO 2 The substrate, the crystal orientation is (100) crystal plane deflected to (110) direction by 0.2°.

[0056] (2) Annealing the substrate: the substrate was baked at a high temperature of 950° C. for 4 hours, and then air-cooled to room temperature.

[0057] (3) Clean the surface of the substrate: LiGaO 2 The substrate was ultrasonically cleaned in deionized water for 8 minutes at room temperature to remove LiGaO 2 The dirt particles on the surface of the substrate are washed with hydrochloric acid, acetone, and ethanol in sequence to remove surface organic matter; the cleaned LiGaO 2 The substrate was blown dry with high-purity dry nitrogen; after that, the LiGaO 2 Put the substrate into a low-temperature molecular beam epitaxy growth chamber, raise the substrate temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com