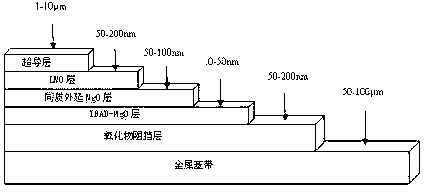

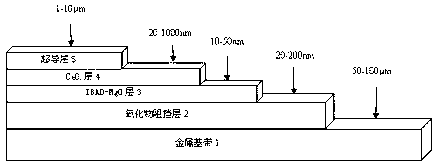

Method for quickly preparing simplified single CeO2 buffering layer on IBAD (Ion Beam Assisted Deposition)-MgO base band by using PLD (Pulsed Laser Deposition) technology

A buffer layer and technical technology, applied in coating, metal material coating process, ion implantation plating, etc., can solve the problems that it is difficult to obtain the critical current density YBCO superconducting layer, the degree of orientation cannot be obtained, etc., and reach the experimental parameters Easy to control, excellent in-plane texture, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

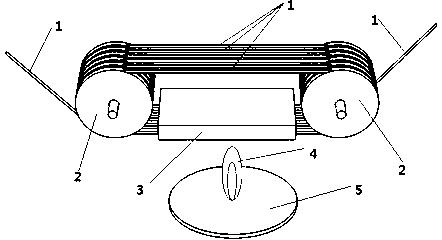

[0040] A Rapid Preparation of Simplified Single CeO on IBAD-MgO Baseband Using PLD Technology 2 The method of buffer layer, this method comprises the following steps:

[0041] Step 1, the CeO prepared by high temperature sintering 2 The oxide target material is loaded into the target holder in the cavity of the multi-channel laser coating system;

[0042] Step 2. Wrap the IBAD-MgO base tape on the rollers in the multi-channel laser coating system;

[0043] Step 3. Close the door of the multi-channel laser coating system and evacuate to 1×10 -7 Torr, then start the heater, and raise the heater to CeO at a rate of 10°C / min. 2 The temperature value required for the buffer layer coating process, that is, 500°C;

[0044] Step 4. After the temperature stabilizes, open the oxygen channel and feed in oxygen. The flow of oxygen is controlled by the gas mass flow meter. The flow of oxygen is 10 SCCM. The gas pressure is adjusted to CeO 2 The air pressure value required for the buff...

Embodiment 2

[0051] A Rapid Preparation of Simplified Single CeO on IBAD-MgO Baseband Using PLD Technology 2 The method of buffer layer, this method comprises the following steps:

[0052] Step 1, the CeO prepared by high temperature sintering 2 The oxide target material is loaded into the target holder in the cavity of the multi-channel laser coating system;

[0053] Step 2. Wrap the IBAD-MgO base tape on the rollers in the multi-channel laser coating system;

[0054] Step 3. Close the door of the multi-channel laser coating system and evacuate to 1×10 -6 Torr, then start the heater, and raise the heater to CeO at a rate of 10°C / min. 2 The temperature value required for the buffer layer coating process, that is, 600°C;

[0055] Step 4. After the temperature stabilizes, open the oxygen channel and feed in oxygen. The flow of oxygen is controlled by the gas mass flow meter. The flow of oxygen is 15 SCCM. The gas pressure is adjusted to CeO 2 The air pressure value required for the buff...

Embodiment 3

[0062] A Rapid Preparation of Simplified Single CeO on IBAD-MgO Baseband Using PLD Technology 2 The method of buffer layer, this method comprises the following steps:

[0063] Step 1, the CeO prepared by high temperature sintering 2 The oxide target material is loaded into the target holder in the cavity of the multi-channel laser coating system;

[0064] Step 2. Wrap the IBAD-MgO base tape on the rollers in the multi-channel laser coating system;

[0065] Step 3. Close the door of the multi-channel laser coating system and evacuate to 5×10 -6 Torr, then start the heater, and raise the heater to CeO at a rate of 10°C / min. 2 The temperature value required for the buffer layer coating process, that is, 750°C;

[0066] Step 4. After the temperature stabilizes, open the oxygen channel and feed in oxygen. The flow of oxygen is controlled by the gas mass flow meter. The flow of oxygen is 15 SCCM. The gas pressure is adjusted to CeO 2 The air pressure value required for the buff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com