Stainless steel substrate solar battery in adjustable-band-gap quantum well structure and preparation method thereof

A technology of solar cells and stainless steel, applied in sustainable manufacturing/processing, circuits, photovoltaic power generation, etc., can solve the problems of poor market competitiveness of thin-film solar cells, poor stability of photo-induced performance of solar cells, and low photoelectric conversion efficiency, etc. Corrosion-resistant tunneling barrier, light weight, and improved photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

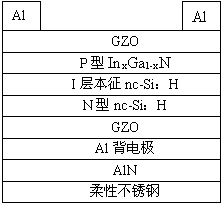

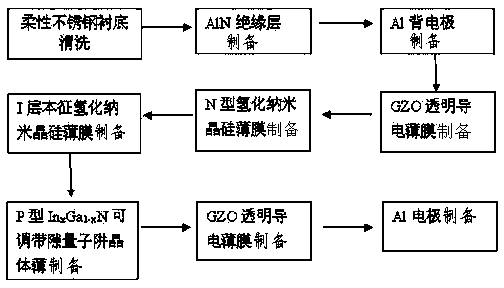

[0036] The structural diagram of the stainless steel substrate solar cell of the adjustable bandgap quantum well structure of the present embodiment is as follows figure 1 Shown, the preparation method is:

[0037] (1) After ultrasonically cleaning the stainless steel flexible substrate with deionized water for 5 minutes, use N 2 Blow dry and send into the magnetron sputtering reaction chamber, at 9.0×10 -4 Under the condition of Pa vacuum, the AlN insulating layer is deposited and prepared, and the Ar and N 2 Mixed gas reaction source, Ar and N 2 The flow rate ratio is 10:1, the substrate substrate is heated to 100°C, and the deposition time is 30min. At this time, the structure is AlN insulating layer / flexible stainless steel substrate;

[0038] (2) Continue to prepare the metal Al back electrode by magnetron sputtering, use Ar as the gas reaction source, the Ar flow rate is 10sccm, the substrate temperature is 50°C, and the deposition time is 3min. The structure...

Embodiment 2

[0049] The structural diagram of the stainless steel substrate solar cell of the adjustable bandgap quantum well structure of the present embodiment is as follows figure 1 Shown, the preparation method is:

[0050] (1) After ultrasonically cleaning the stainless steel flexible substrate with deionized water for 5 minutes, use N 2 Blow dry and send into the magnetron sputtering reaction chamber, at 9.0×10 -4 Under the condition of Pa vacuum, the AlN insulating layer is deposited and prepared, and the Ar and N 2 Mixed gas reaction source, Ar and N 2 The flow rate ratio is 10:1, the substrate substrate is heated to 150°C, and the deposition time is 45min. At this time, the structure is AlN insulating layer / flexible stainless steel substrate;

[0051] (2) Continue to prepare the metal Al back electrode by magnetron sputtering, use Ar as the gas reaction source, the Ar flow rate is 12sccm, the substrate temperature is 150°C, and the deposition time is 5min. The structure at...

Embodiment 3

[0059] The structural diagram of the stainless steel substrate solar cell of the adjustable bandgap quantum well structure of the present embodiment is as follows figure 1 Shown, the preparation method is:

[0060] (1) After ultrasonically cleaning the stainless steel flexible substrate with deionized water for 5 minutes, use N 2 Blow dry and send into the magnetron sputtering reaction chamber, at 9.0×10 -4 Under the condition of Pa vacuum, the AlN insulating layer is deposited and prepared, and the Ar and N 2 Mixed gas reaction source, Ar and N 2 The flow rate ratio is 10:1, the substrate substrate is heated to 300°C, and the deposition time is 60min. At this time, the structure is AlN insulating layer / flexible stainless steel substrate;

[0061] (2) Continue to prepare the metal Al back electrode by magnetron sputtering, use Ar as the gas reaction source, the Ar flow rate is 20sccm, the substrate temperature is 350°C, and the deposition time is 10min. The structure a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com