Y-Ba-Cu-O coating conductor with conducting buffer layer and preparing process

A conductive buffer, yttrium barium copper oxide technology, applied in superconducting/high-conducting conductors, usage of superconducting elements, manufacturing/processing of superconducting devices, etc., can solve problems such as poor superconducting performance of YBCO superconducting film, and achieve experimental results The parameters are easy to control, the oxygen diffusion coefficient is small, and the effect of good thermal expansion coefficient transition characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

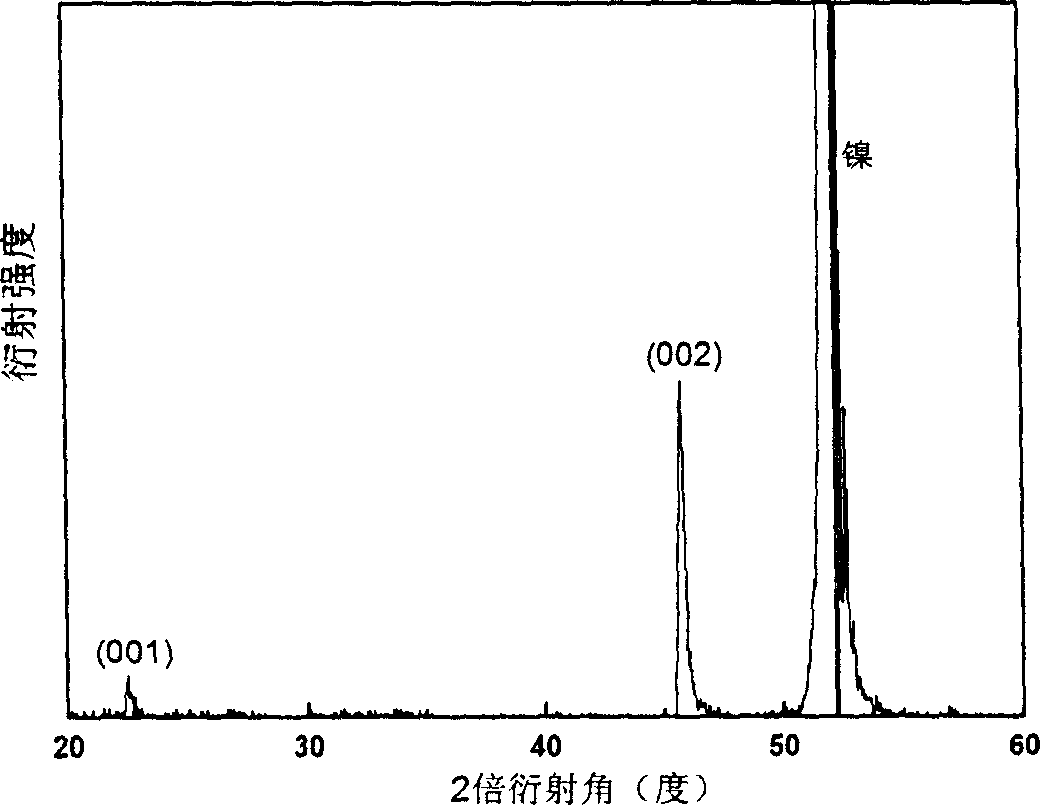

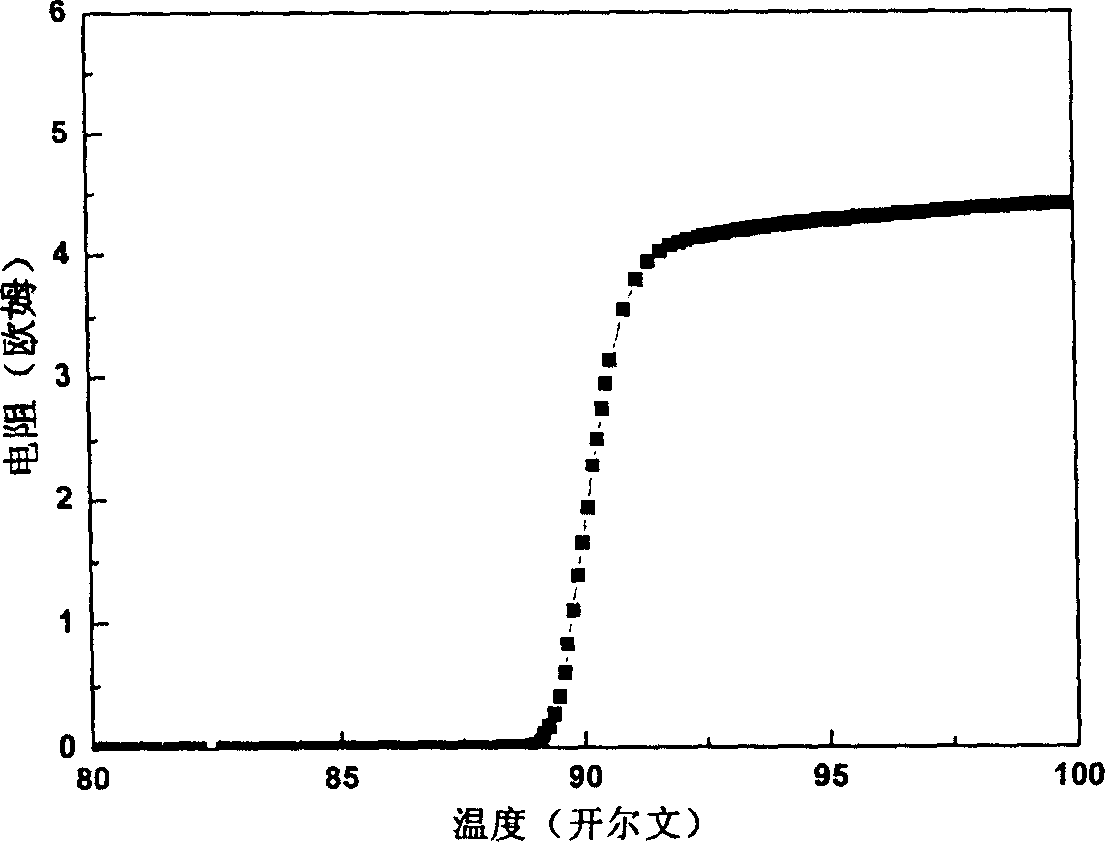

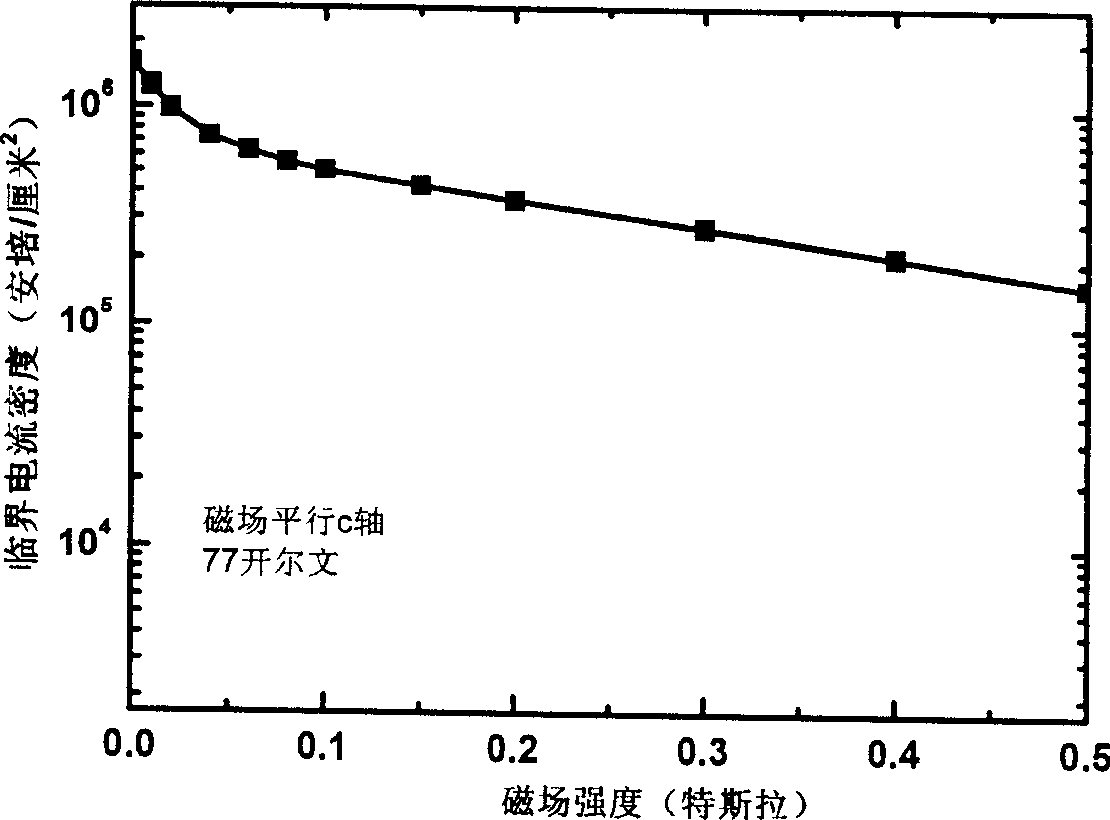

[0032] Embodiment 1: the present embodiment has SrTi 0.95 Nb 0.05 o 3 YBCO-coated conductors for the conductive buffer layer, comprising a cubic textured Ni substrate with a thickness of 0.2 μm, on which a layer of SrTi with a thickness of 100 nm is grown 0.95 Nb 0.05 o 3 conductive buffer layer, then the SrTi 0.95 Nb 0.05 o 3 On the conductive buffer layer, a yttrium barium copper oxide superconducting layer with a thickness of 600nm is grown again.

[0033] The method of this embodiment utilizes the conventional pulsed laser deposition process and is carried out in pulsed laser deposition equipment; the metal baseband is selected from the Ni baseband with cubic texture, and SrTi with 100nm is prepared thereon. 0.95 Nb 0.05 o 3 The yttrium barium copper oxide coated conductor of the conductive buffer layer, its specific process is as follows:

[0034] 1. The SrTi prepared by high temperature sintering 0.95 Nb 0.05 o 3 The ceramic target is installed on the target...

Embodiment 2

[0045] Embodiment 2: the present embodiment has SrTi 0.7 Nb 0.3 o 3 YBCO-coated conductors for conductive buffer layers, including a cubic textured Ni substrate with a thickness of 0.2 μm, and a layer of SrTi with a thickness of 500 nm grown on the cubic textured Ni substrate 0.7 Nb 0.3 o 3 conductive buffer layer, the SrTi 0.7 Nb 0.3 o 3 The conductive buffer layer grows a yttrium barium copper oxide superconducting layer with a thickness of 600nm.

[0046] Fabrication of SrTi with 500nm on cubic textured Ni substrate 0.7 Nb 0.3 o 3 The conductive buffer layer of the YBCO coated conductor is as follows:

[0047] The preparation method of the present embodiment is different from embodiment 1 except step 1 and the process of preparing the conductive buffer layer, all the other repeat the steps in the embodiment 1, the process of preparing the conductive buffer layer is as follows:

[0048] Change to pre-sintered SrTi on the target support 0.7 Nb 0.3 o 3 ceramic ta...

Embodiment 3

[0051] Embodiment 3: the present embodiment has SrTi 0.9 In 0.1 o 3 The yttrium barium copper oxide coated conductor of the conductive buffer layer includes a Ni alloy substrate with a cubic texture of 0.2 μm in thickness, and a layer of SrTi with a thickness of 200 nm is grown on the Ni alloy substrate with a cubic texture. 0.9 In 0.1 o 3 conductive buffer layer, the SrTi 0.9 In 0.1 o 3 On the conductive buffer layer, a yttrium-barium-copper-oxygen superconducting layer with a thickness of 600nm is grown again.

[0052] Fabrication of SrTi with 200nm on Ni alloy substrate with cubic texture 0.9 In 0.1 o 3 The conductive buffer layer of the YBCO coated conductor is as follows:

[0053] 1. The SrTi prepared by high temperature sintering 0.9 In 0.1 o 3 The ceramic target is installed on the target holder in the reaction chamber;

[0054] 2. Remove the oxide impurities on the surface of the Ni alloy substrate;

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com