Method for growing single-layer graphene thin film by virtue of low-temperature chemical vapor deposition

A chemical vapor deposition and single-layer graphene technology, which is applied in the field of two-dimensional thin film material preparation, can solve the problems that the graphene growth preparation technology is difficult to meet people's needs, and the potential is difficult to be exerted.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

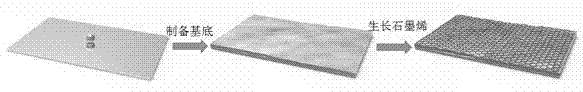

[0066] A method for growing a single-layer graphene film by low-temperature chemical vapor deposition, comprising the following steps (the flow chart of preparing graphene by chemical vapor deposition at low temperature is as follows figure 1 shown):

[0067] A nickel foil with a thickness of 25 μm was selected as the metal substrate, and the nickel foil was soaked in acetic acid, ethanol, and ultrapure aqueous solution with a volume ratio of 1:1:1 for 5 min, and then dried. Then the gallium ball whose mass fraction is 35.0% of the nickel foil is placed in the very center of the nickel foil.

[0068] Push the metal substrate into the reaction furnace, inject 300 sccm of hydrogen as a protective gas, and keep it at a constant temperature of 1000 degrees for 30 minutes to allow the two to react to form a uniform mixed-phase surface.

[0069] Put the metal substrate into the polishing solution, polish it at 5V for 30 seconds, turn off the power, and clean the metal substrate.

...

Embodiment 2

[0079] A method for growing single-layer graphene film by low-temperature chemical vapor deposition, comprising the following steps:

[0080] A cobalt foil with a thickness of 250 μm was selected as the metal substrate, and the cobalt foil was soaked in 1:1:1 acetic acid, ethanol, and ultrapure aqueous solution for 10 minutes, and then dried. Then place the indium ball whose mass fraction is 70.0% of the cobalt foil on the very center of the nickel foil.

[0081] The metal substrate is pushed into the reaction furnace, 500 sccm of argon gas is introduced as a protective gas, and the temperature is maintained at a constant temperature of 400 degrees for 120 minutes, so that the two react to form a uniform mixed phase surface.

[0082] Put the metal substrate in the polishing solution, polish it at 3V for 120 seconds, turn off the power, clean the metal substrate, and then perform mechanical polishing on it.

[0083] Put the metal substrate after the above treatment into the ce...

Embodiment 3

[0086] A method for growing single-layer graphene film by low-temperature chemical vapor deposition, comprising the following steps:

[0087] Select indium with a thickness of 50 μm as the metal substrate, soak the indium ball in acetic acid, ethanol, and ultrapure aqueous solution with a volume ratio of 1:1:1 for 10 minutes, and dry it. Then the gallium sphere whose mass fraction is 20.0% of the indium sphere is placed in the very center of the indium sphere.

[0088] Push the metal substrate into the reaction furnace, inject 600 sccm of argon as a protective gas, and keep it at a constant temperature of 500 degrees for 60 minutes to allow the two to react to form a uniform mixed-phase surface.

[0089] Put the metal substrate in the polishing solution, polish it at 3V for 120 seconds, turn off the power, and clean the metal substrate.

[0090] Put the above treated metal substrate into the center of the atmosphere tube furnace, pass hydrogen and nitrogen into the tube furna...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com