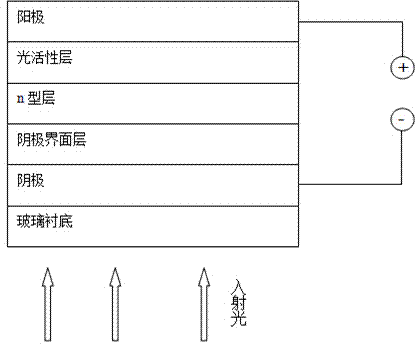

Inverted-structure CdTe nanocrystalline heterojunction high-efficiency solar cell processed by solution method, and preparation method of solar cell

A technology of solar cells and inverted structures, which is applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, and can solve the problems of difficult device stability, unfavorable carrier separation and transmission, and reduced light absorption. Efficiency and other issues, to improve battery performance, reduce roughness, improve the effect of the interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

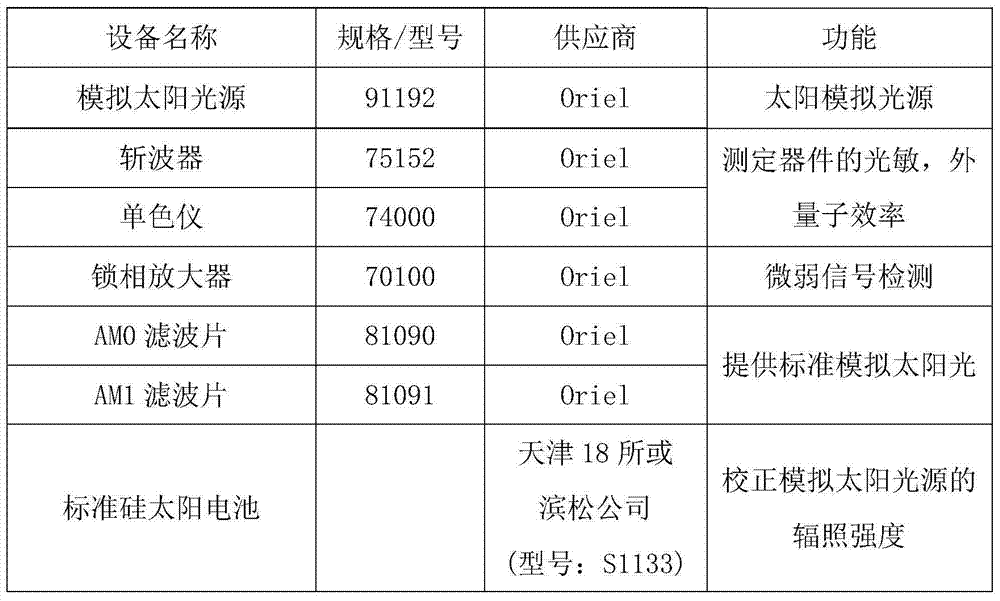

[0048] (3) Preparation of the cathode interface layer: place the ITO sheet on a homogenizer (KW-4A type), drop the ZnO sol prepared in step (2), spin-coat at high speed (3000rpm, time 20s), scrape off The ZnO layer at the cathode position was placed on a heating platform, firstly heat-treated at 200°C for 10 minutes, then heated at 400°C for 10 minutes, cooled to room temperature, placed in acetone and isopropanol and ultrasonicated for 10 minutes (ultrasonic power 1000W), blown with a nitrogen gun Dry to obtain a cathode interface layer with a thickness of 40 nm.

[0049] (4) Preparation of n-type layer:

[0050] ① Preparation of CdSe nanocrystals: Weigh cadmium myristate (1.6mmol, 906mg), trioctylphosphine oxide 2.35g, myristic acid (myristic acid, C 13 h 26COOH, 92mg) was added into a 50ml three-necked bottle (the mouth of the bottle was equipped with a thermometer, a condenser tube, and an air guide tube), and heated to 240°C under nitrogen protection. At this time, the ...

Embodiment 1

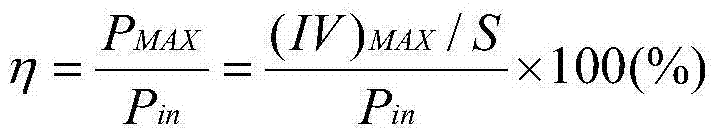

[0068] Effect of different CdSe layer thicknesses on CdTe nanocrystalline cells.

[0069] CdSe nanocrystalline layers with a thickness of 30nm, 60nm, 90nm, 120nm, and 150nm were selected as the n-type layer, ZnO was set at 40nm, CdTe layer was set at 500nm, and CdCl 2 The sintering temperature was set at 340°C to prepare CdTe nanocrystalline solar cells. Table 2 compares the device results for different CdSe layer thicknesses.

[0070] Table 2 Effect of CdSe layer thickness on performance of CdTe nanocrystalline solar cells

[0071]

[0072] Table 2 compares the effect of CdSe layer thickness on device performance. The results of multiple experiments show that when the thickness of the CdSe nanocrystalline window layer is 60-90nm, the open-circuit voltage of the device rises significantly, and the performance is obviously improved. Under this thickness, it not only ensures that enough light can pass through the CdSe layer to reach the photoactive area, but also ensures t...

Embodiment 2

[0074] Effect of different CdTe layer thicknesses on CdTe nanocrystalline cells.

[0075] Using a specific implementation method, the inverted structure is prepared as an ITO / ZnO / CdSe / CdTe / Au inverted structure device, wherein the thickness of the CdSe layer is 60nm, the thickness of the CdTe layer is respectively 200nm, 300nm, 400nm, 500nm, 600nm, and 700nm, and the thickness of the ZnO layer is 40nm, CdCl 2 The sintering temperature was 340°C. Detect the short-circuit current density (mA / cm2) of each device 2 ), open circuit voltage (V), fill factor (%), energy conversion efficiency (%). Table 3 compares the results for devices with different CdTe layer thicknesses:

[0076] Table 3 Effect of CdTe layer thickness on performance of CdTe nanocrystalline solar cells

[0077]

[0078] It can be seen from Table 3 that when the thickness of the CdTe layer is about 500nm, the energy conversion efficiency is the highest. Under this thickness, the active layer with a certain t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com