Method for weakening and even eliminating segregation at grain boundary of copper alloy

A copper alloy and grain boundary technology, which is applied in the field of weakening segregation at the alloy grain boundary, can solve problems that are difficult to apply to industrial production of bulk materials, and achieve the effect of improving potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

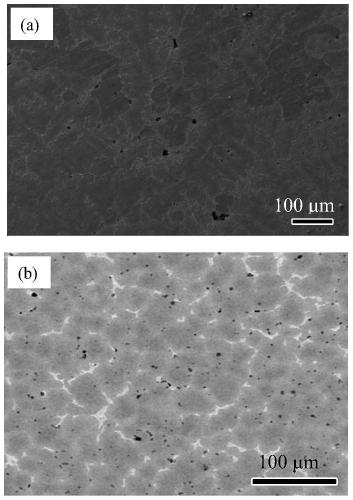

[0032] The present invention is described in detail below through exemplary embodiments. It should be pointed out that those skilled in the art can easily understand that the following examples are only some exemplary examples of the method of the present invention given by way of example, and do not imply any limitation to the present invention.

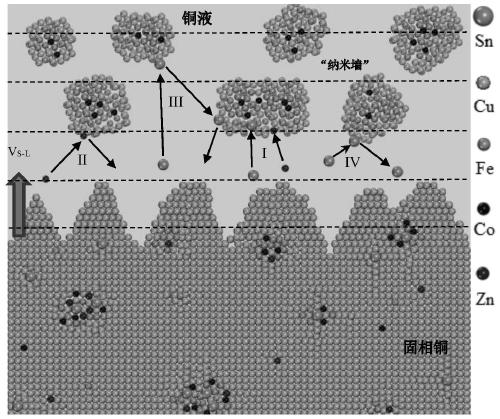

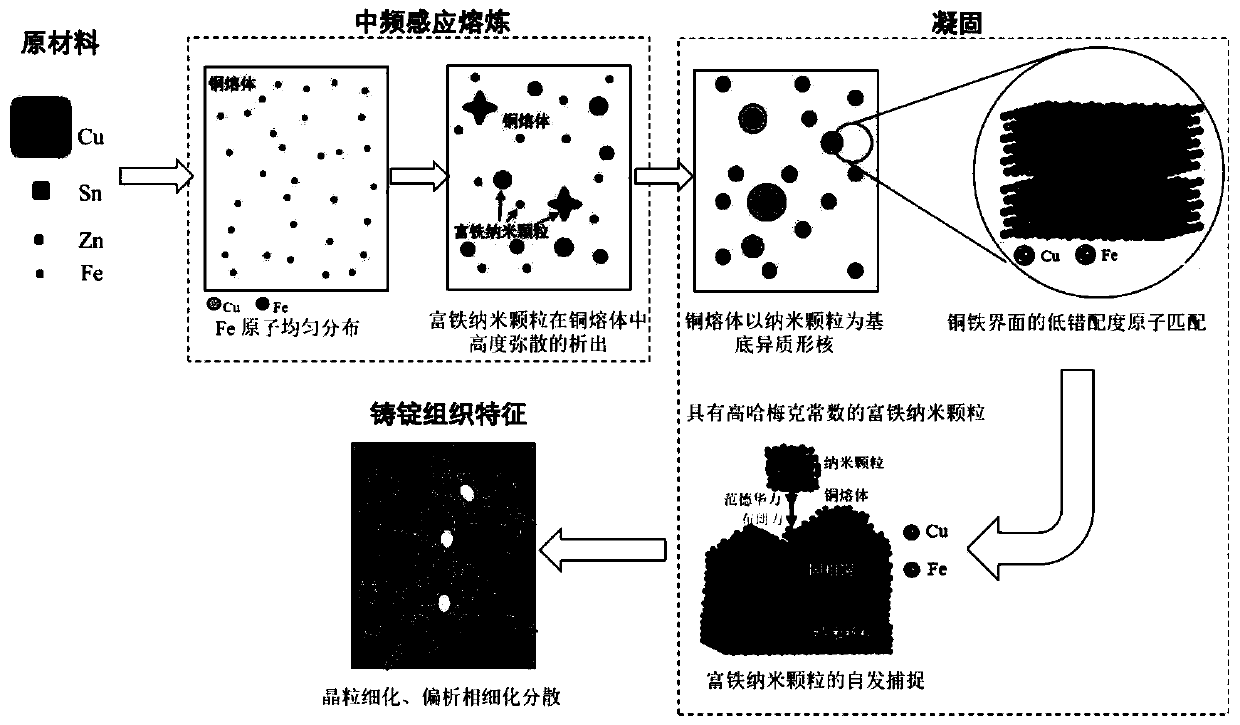

[0033] The invention relates to a method for weakening or even eliminating segregation at grain boundaries in tin bronze alloys. Firstly, highly dense in-situ precipitated nanoparticles are prepared in a copper melt. Alloying elements and the nanoparticles they form need to meet three conditions: the nanophase-forming elements meet the conditions of early precipitation in the matrix melt in thermodynamics; the lattice mismatch between the nanoparticles and the matrix is small enough, and the solidification process passes through The heterogeneous nucleation of particles produces a significant grain refinement effect, and at the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com