Flexible cable used for new energy automobile

A new energy vehicle, flexible cable technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of insufficient reliability and practicability, limited heat dissipation, self-cooling effect, and high processing cost, and achieves excellent heat dissipation effect and molding difficulty. The effect of small size and low molding cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

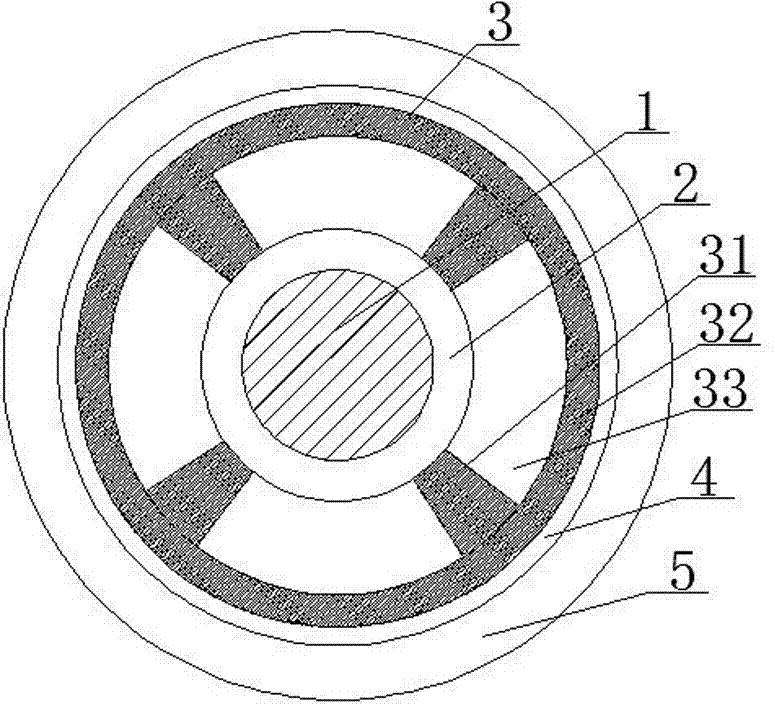

[0027] see figure 1 As shown, the present invention is a high-voltage flexible cable for new energy charging vehicles, which is mainly composed of a conductor 1 and an insulating layer 2, a cooling layer 3, a tape layer 4 and an armor layer 5 that are sequentially covered from the inside to the outside. The insulation layer 2, the cooling layer 3, the cladding layer 4 and the armor layer 5 are radially formed in layers with the conductor 1 as the center of the circle.

[0028] Wherein, conductor 1 is the sixth soft copper conductor. The diameter of the constituent copper wire of the soft copper conductor is about 0.20mm.

[0029] The insulating layer 2 is extruded by high temperature resistant ceramic silicon rubber, that is, the insulating layer 2 is formed on the outer surface of the conductor 1 by extrusion molding. The thickness of the insulating layer 2 is about 2.0mm.

[0030]The cooling layer 3 is extruded from a high-strength, low-smoke, halogen-free flame-retardant...

Embodiment 2

[0034] The invention is a high-voltage flexible cable for new energy charging vehicles, which is mainly composed of a conductor and an insulating layer, a cooling layer, a tape layer and an armor layer covered in sequence from the inside to the outside. The insulation layer, the cooling layer, the tape Layers and armor layers are radially layered with the conductor as the center.

[0035] Among them, the conductor is the sixth tinned annealed copper conductor. The annealed copper conductor consists of a tinned copper wire with a diameter of about 0.25mm.

[0036] The insulating layer is extruded with high temperature resistant ceramic silicone rubber, that is, the insulating layer is formed on the outer surface of the conductor by extrusion molding. The thickness of the insulating layer is about 2.0mm.

[0037] The cooling layer is extruded with high-strength, low-smoke, halogen-free flame-retardant material-polyolefin, and the hardness of the polyolefin material is about Sh...

Embodiment 3

[0041] The invention is a high-voltage flexible cable for new energy charging vehicles, which is mainly composed of a conductor and an insulating layer, a cooling layer, a tape layer and an armor layer covered in sequence from the inside to the outside. The insulation layer, the cooling layer, the tape Layers and armor layers are radially layered with the conductor as the center.

[0042] Among them, the conductor is the sixth soft copper conductor. The diameter of the constituent copper wires of the soft copper conductor is about 0.15mm.

[0043] The insulating layer is extruded with high temperature resistant ceramic silicone rubber, that is, the insulating layer is formed on the outer surface of the conductor by extrusion molding. The thickness of the insulating layer is about 0.80mm.

[0044] The cooling layer is extruded with high-strength, low-smoke, halogen-free flame-retardant material-polyolefin, and the hardness of the polyolefin material is about Shore 85A. In th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com