Glucose polymer peritoneal dialysis solution and preparation process thereof

A technology of glucose polymer and peritoneal dialysis solution, which is applied in the field of glucose polymer peritoneal dialysis solution and its preparation process, can solve the problems of affecting the curative effect of peritoneal dialysis, fast degradation speed, and small size of glucose molecules, so as to improve the curative effect of clinical use, Reduced damage and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

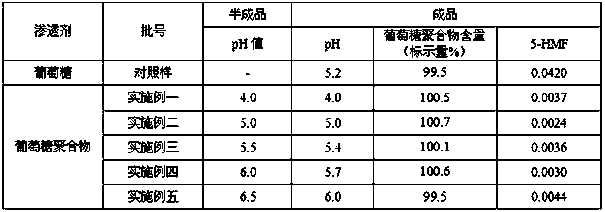

Embodiment 1

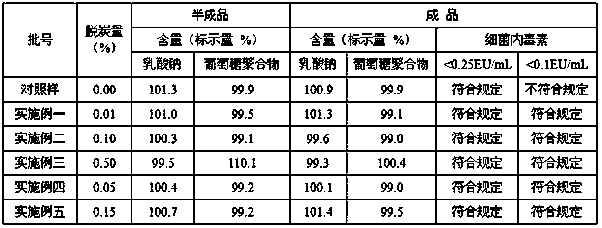

[0030] In this embodiment, the product scale of producing 300 bags of 2.0L specification is taken as an example, and the preparation volume is 600L.

[0031] (1) Weighing: glucose polymer 45kg, magnesium chloride 0.030kg, calcium chloride 0.154kg, sodium chloride 3.21kg, sodium lactate 2.688kg, where the glucose polymer is icodextrin.

[0032] (2) Add 80% of the full batch volume of fresh water for injection into the concentrated preparation container, and the temperature of the water for injection is 50°C; then, add 100% of the prescription amount of glucose polymer, calcium chloride, sodium chloride, magnesium chloride, and sodium lactate , stir to dissolve.

[0033] (3) After all the above components are dissolved, add 0.01% (W / V) activated carbon, stir well, keep warm and stir for adsorption at 50-60°C, and decarbonize and filter.

[0034] (4) Transfer the above liquid medicine to a dilute preparation tank, add the remaining water for injection after cooling, measure the ...

Embodiment 2

[0038] In this embodiment, the product scale of producing 600 bags of 1.0L specification is taken as an example, and the preparation volume is 600L.

[0039] (1) Weighing: 60kg of glucose polymer, 0.030kg of magnesium chloride, 0.154kg of calcium chloride, 3.21kg of sodium chloride, 2.688kg of sodium lactate, where the glucose polymer is maltodextrin.

[0040] (2) Add 70% of the full batch volume of fresh water for injection into the concentrated preparation container, and the temperature of the water for injection is 60°C; then, add 100% of the prescription amount of glucose polymer, calcium chloride, sodium chloride, magnesium chloride, and sodium lactate, Stir to dissolve.

[0041] (3) After all the above components are dissolved, add 0.1% (W / V) activated carbon, stir well, keep warm and stir for adsorption at 50°C, and decarbonize and filter.

[0042] (4) Transfer the above medicinal solution to the dilute preparation tank, add the remaining water for injection after cool...

Embodiment 3

[0046] In this embodiment, the product scale of producing 200 bags of 3.0 L is taken as an example, and the preparation volume is 600 L.

[0047] (1) Weighing: glucose polymer 90kg, magnesium chloride 0.030kg, calcium chloride 0.154kg, sodium chloride 3.21kg, sodium lactate 2.688kg, where the glucose polymer is icodextrin and maltodextrin according to the quality of 1:1 than the composition of the mixture.

[0048] (2) Add 60% of the full batch volume of fresh water for injection to the concentrated preparation container, and the temperature of the water for injection is 80°C; then, add 100% of the prescription amount of glucose polymer, calcium chloride, sodium chloride, magnesium chloride, and sodium lactate , stir to dissolve.

[0049] (3) Add 0.5% (W / V) activated carbon after it is completely dissolved, stir well, keep warm and stir for adsorption at 60°C, and decarbonize and filter.

[0050] (4) Transfer the above medicinal solution to a dilute preparation tank, add the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com